An article to understand new energy vehicle drive motors and domestic mainstream suppliers

The component with the highest production cost of a new energy vehicle is the power battery, accounting for about 30%, while the motor accounts for 10%. At present, many domestic manufacturers are producing and developing new energy vehicle motors. In this field, domestically produced technology is still relatively advanced, which has more advantages than engines for fuel vehicles, and there are many fewer technical barriers. Therefore, the manufacture of domestically produced motors The standard is no worse than that of overseas companies.

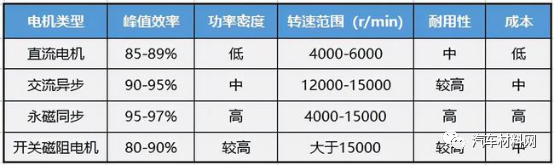

At present, the classification of motors mainly includes four types: DC, AC induction, permanent magnet synchronous and switched reluctance. At present, permanent magnet synchronous motor is the mainstream type of motor due to its better performance. The price of the AC asynchronous motor is moderate, but the performance is slightly inferior, and it is used by some manufacturers in the United States and China. The main advantage of the switched reluctance motor lies in its lower price, but at the same time there are technical problems of noise and vibration. If these problems can be solved, the switched reluctance motor will have a large market. At this stage, the drive motors suitable for new energy vehicles mainly include permanent magnet synchronous, AC asynchronous and switched reluctance. Because of their different characteristics, each has its application occasions.

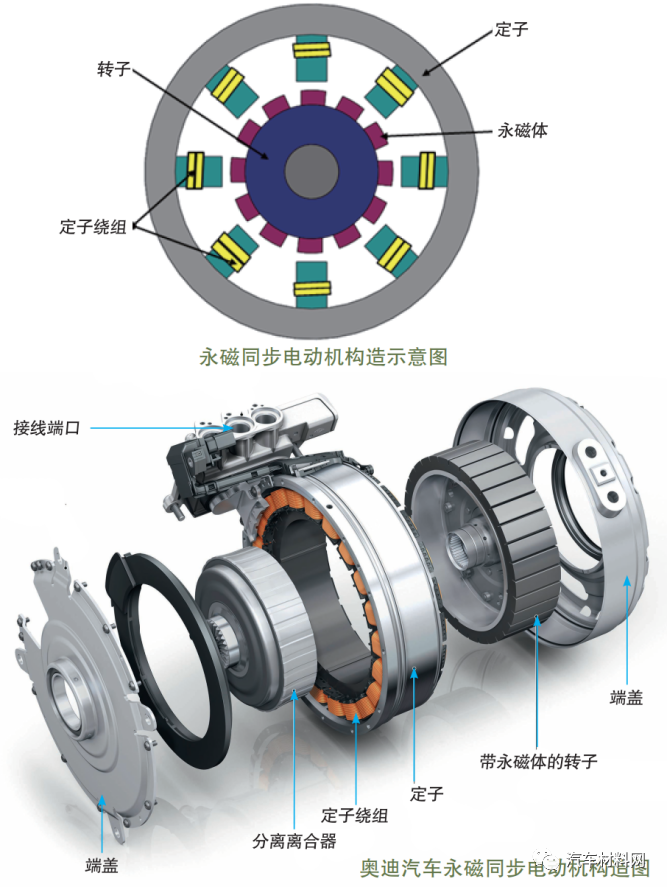

The permanent magnet synchronous motor is small in size, light in weight, high in power density, high in reliability, high in speed regulation accuracy, and fast in response; but its maximum power is low and its cost is high. Since the permanent magnet synchronous motor has the highest power density, its working efficiency can reach up to 97%, and it can output the maximum power and acceleration for the vehicle. Therefore, it is mainly used in new energy passenger vehicles that require the highest energy volume ratio.

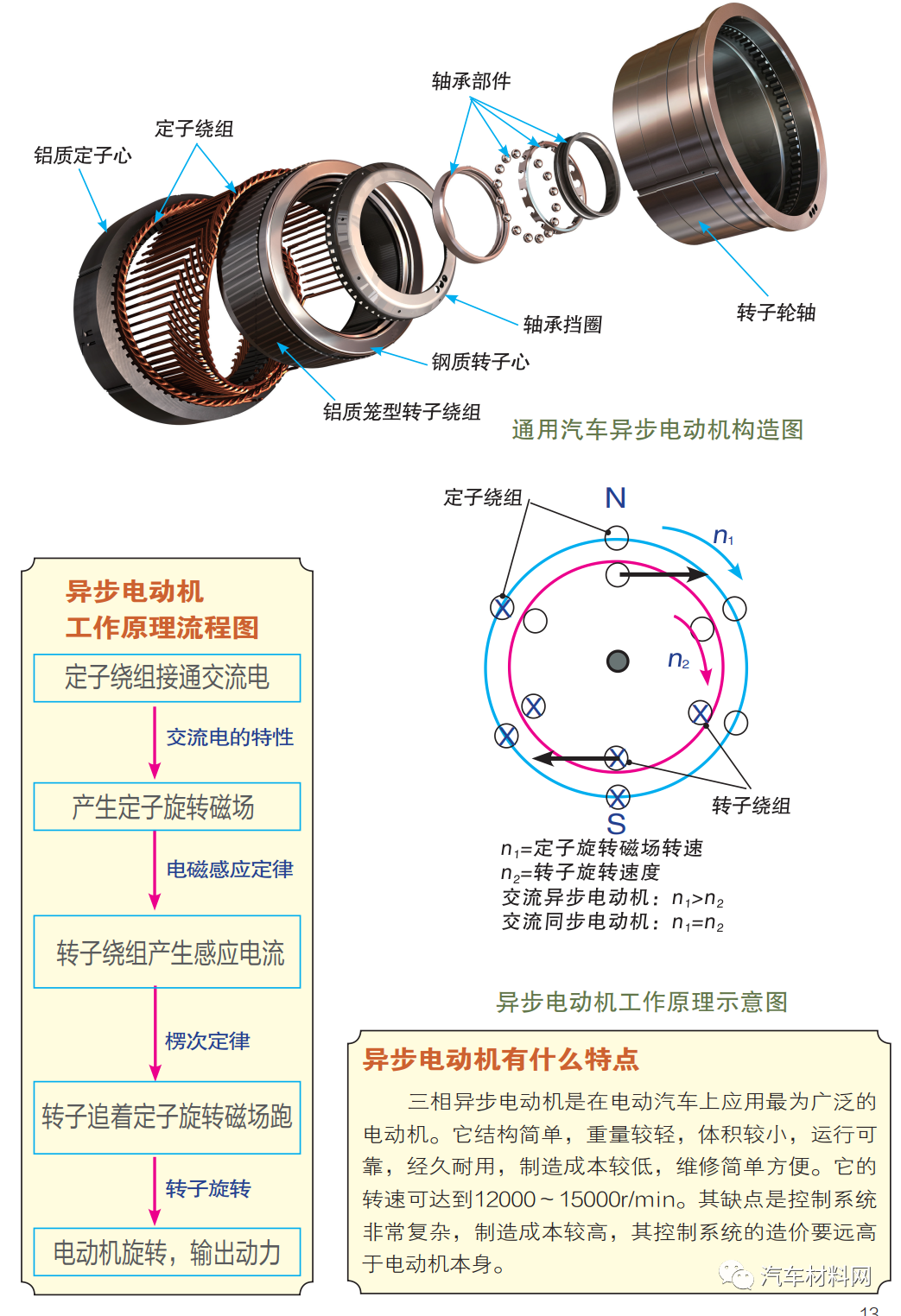

AC asynchronous motors are low in price and reliable in operation; however, their low power density, complex control, and small speed range are inherent limitations. The price advantage makes it widely used in new energy buses. Switched reluctance motors are low in price, simple and reliable in circuit, and wide in speed regulation range; however, they have large vibration and noise, complex control system, and will generate a large pulse current to the DC power supply, and are used in large passenger cars.

New energy vehicle drive motors are developing toward the goals of: small and lightweight; high efficiency; better torque characteristics; long service life, high reliability; low noise; low price.

AC asynchronous motors are mainly used by American car companies headed by Tesla and some European companies. On the one hand, this is related to Tesla’s initial technology path choice, mainly because of the scarcity of rare earth resources, the low price of AC induction motors, and the large size does not hinder American cars; on the other hand, the developed highway network in the United States , the high-speed range efficiency performance of the AC motor is excellent.

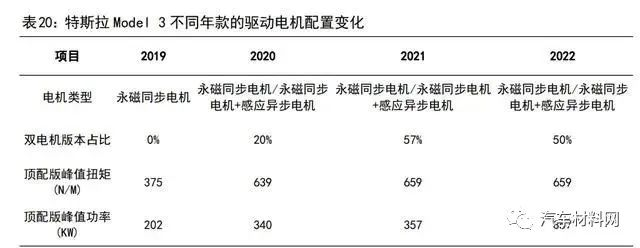

Tesla’s early models mostly used induction asynchronous motors (Roadster, etc.). The 2019 overseas Tesla Model 3 is still equipped with an induction asynchronous motor in the single-motor version, and a front-drive permanent magnet synchronous motor in the dual-motor version. Rear drive induction asynchronous motor. The 2019 domestic version of the Tesla Model 3 single-motor version is equipped with a permanent magnet synchronous motor. At this stage, Tesla Model 3, Model Y, Model S, Model X and other models are equipped with a permanent magnet synchronous motor on the single motor version, and a permanent magnet synchronous motor + induction asynchronous motor on the dual motor version. The three-motor version of the new Tesla Model S Plaid is equipped with permanent magnet synchronous motors. Overall, the trend of Tesla's drive motor configuration is increasing in number and performance, and the penetration rate of permanent magnet synchronous motors is getting higher and higher.

Based on the complementary performance of permanent magnet synchronous motors and induction asynchronous motors that have been analyzed in detail above, Tesla's main performance models all use a dual-motor solution with permanent magnet synchronous motors and induction asynchronous motors. Tesla's new Model S Plaid version is equipped with a three-motor solution that uses permanent magnet synchronous motors, and has implemented many of Tesla's cutting-edge technologies on drive motors.

The most widely used motors for new energy vehicles in other countries including China and Japan are still permanent magnet synchronous motors. Suitability to national road conditions is the main factor. Permanent magnet synchronous motors can still maintain high efficiency during repeated start and stop, acceleration and deceleration, and are the best choice for working conditions with limited high-speed road networks.

Automobile companies such as Toyota, Honda, and Nissan in Japan basically use permanent magnet synchronous motor drive systems, such as Toyota's Prius and Honda's CIVIC. Because in Japan, there are many companies that supply rare earth magnets used in permanent magnet motors, and most of the cars run at low and medium speeds, so it is more appropriate to use permanent magnet synchronous motors with higher efficiency during acceleration and deceleration. Japan is a world leader in the development of hybrid vehicles, the most famous of which is the Toyota Prius.

my country is rich in rare earth reserves, and Japan's rare earth permanent magnet industry has a supporting foundation is also an important factor. At present, the use of permanent magnet synchronous motors in my country's new energy vehicles accounts for more than 90%, and the motor technology is close to the world's advanced level. Therefore, it is expected that permanent magnet motors will occupy the motor market of China's new energy vehicles for a long time.

Judging from the popular models in the domestic market, most of them use permanent magnet synchronous motors, such as BYD Han, Model 3/Y, Ideal one, Xiaopeng P7, Weilai ES6, EC6, Aion Y, LX, etc.

Some models are equipped with front and rear dual motors, which will be used in combination with permanent magnet synchronous and AC asynchronous. For example, BYD has always used permanent magnet synchronous motors, and as early as the 2015 BYD Tang New Energy, it has implemented a dual-motor four-wheel drive structure, which is forward-looking and advanced. In terms of pure electric platform, BYD's latest E platform 3.0 adopts the technical solution of front-drive induction asynchronous motor + rear-drive permanent magnet synchronous motor. Dual motors for maximum output.

In general, permanent magnet synchronous motors have distinct advantages over induction motors. However, the current cruising range of pure electric vehicles is bound to be an extremely important indicator, and the high efficiency of permanent magnet synchronous motors can better improve the cruising range. Moreover, the successful development of NdFeB permanent magnets with high heat resistance and high magnetic properties and the further development and improvement of power electronic components have further improved the development of rare earth permanent magnet synchronous motors. But as far as the current development trend is concerned, the permanent magnet synchronous motor seems to have a better prospect. With the rapid development of new energy vehicle drive technology, many new structures or new concept motors have been put into research. Among them, the new permanent magnet brushless motor is one of the most promising motors at present, including hybrid excitation type, hub type, double stator type, memory type and magnetic gear compound type. In addition, amorphous motors have also begun to enter the field of new energy vehicles. As a new generation of high-performance motors, their own advantages will definitely play a huge role in promoting the development of the new energy vehicle industry.

At present, the domestic new energy vehicle motor industry is mainly divided into three categories: car companies, new energy vehicle motor companies, and traditional motor manufacturers.

According to data from Gaogong Intelligent Automobile Research Institute, in 2022, the Chinese market (excluding imports and exports) will be equipped with drive motors (including single motors, dual motors, and three motors) of new energy passenger vehicles. 81.65%; Among them, 922,000 new cars were delivered with dual motors, a year-on-year increase of 90.3%, accounting for 17.62% of the market, and still maintaining a rapid growth trend.

The top five in the domestic motor market share are BYD's Fudi Power (28.26%), Tesla (12.87%), Founder (5.60%), Nidec (5.27%), and Inovance Technology (5.15%).

Industry experts predict that by 2025, the market size of electric motor control for new energy vehicles will exceed 300 billion yuan. From the perspective of the development trend of the motor industry, domestic new energy car companies have focused on the direction of independent research and development, such as BAIC, NIO, BYD, and Geely all have their own or invested motor production plants. There are also many car companies that choose to make joint ventures with motor manufacturers. Traditional motor manufacturers such as GAC, FAW, and BAIC have established joint ventures with Nidec and Dayang Electric to customize new energy vehicle motors and power systems for car companies. Car companies are the leading parties and have more say.

Whether it is independent research and development or joint venture production, it will promote the development of the domestic motor industry and the improvement of technology. In the domestic market, BYD and Tesla firmly occupy the first and second places. With the help of their own technological advantages and supply chain resources, independent research and development and production of motors will help control costs and supply. According to the current development trend of the new energy vehicle industry, more and more car companies will turn to their own research and development and production of motors in the future, and master the core technologies of "three electric" (battery, motor, and electronic control) of new energy vehicles.

XINDA

XINDA