Answer:The technology of electric loader motors is developing in the direction of high efficiency, intelligence and greenness. Whether it is to improve work efficiency or to reduce the impact on the environment, all of this demonstrates the infinite potenti...

Answer:1. Engine parts: including engine, piston, cylinder head, crankshaft, camshaft, etc. 2. Chassis parts: including suspension system, brake system, steering system, transmission system, etc.

Answer:The general specifications of induction motors

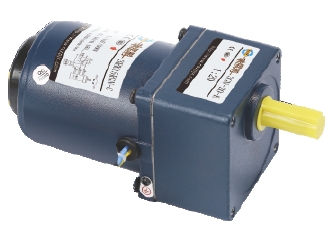

Answer:AC reduction motor with gearbox and regulator model representation method

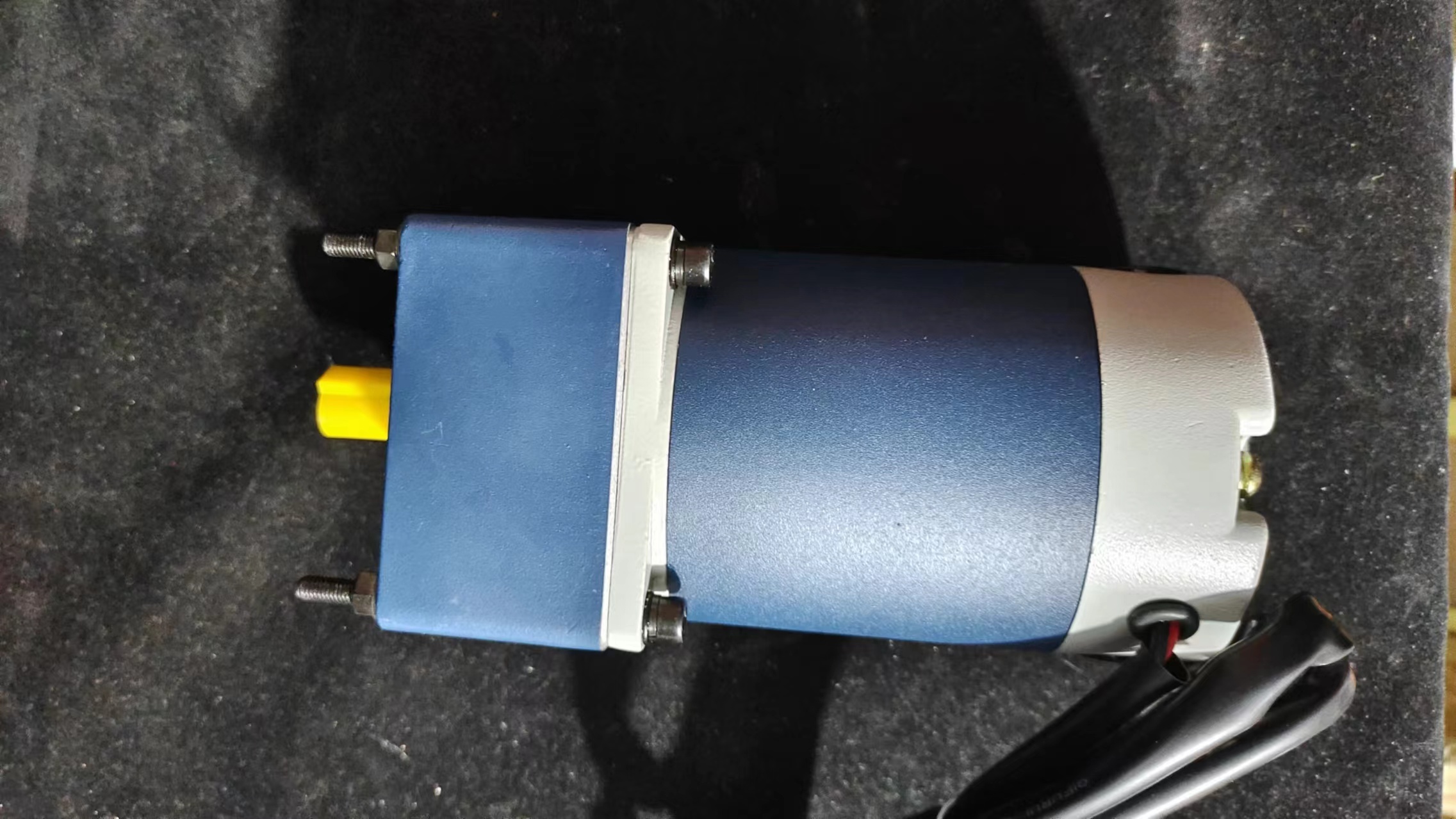

Answer:Before the reduction motor is put into operation, it needs to be installed with an aluminum shell, which can make the motor heat dissipation better: when the motor is working, due to high-speed operation, the motor itself generates excessive temperat...

Answer:Keep the motor clean: In order to ensure the normal operation of the medium-sized reduction motor, you must pay attention to cleaning the reduction motor at ordinary times. Only by ensuring that the reduction motor is clean and dust-free can the norm...

Answer:The selection of AC motor and its gearbox

Answer:method for calculating motor capacity

Answer:Most industrial control and automatic control applications belong to this category. In such applications, energy is often transmitted, so there are special requirements for the dynamic response of speed and torque, and the requirements for the contro...