Noise Fault Analysis of Vertical Motor

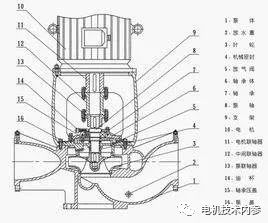

A motorist said that their plant produced a YE3-355-4 export vertical motor, but due to excessive vibration and noise, it didn't met the assessment requirements and was not allowed to leave the factory. After consulting and discussing with the company's experts, it was decided to make some fine adjustments in the axial direction of the motor. The original faults were all eliminated during the test again. In response to this problem, Ms. participated in the discussion on the characteristics of large-scale vertical motors, shared experience, and communicated with everyone.

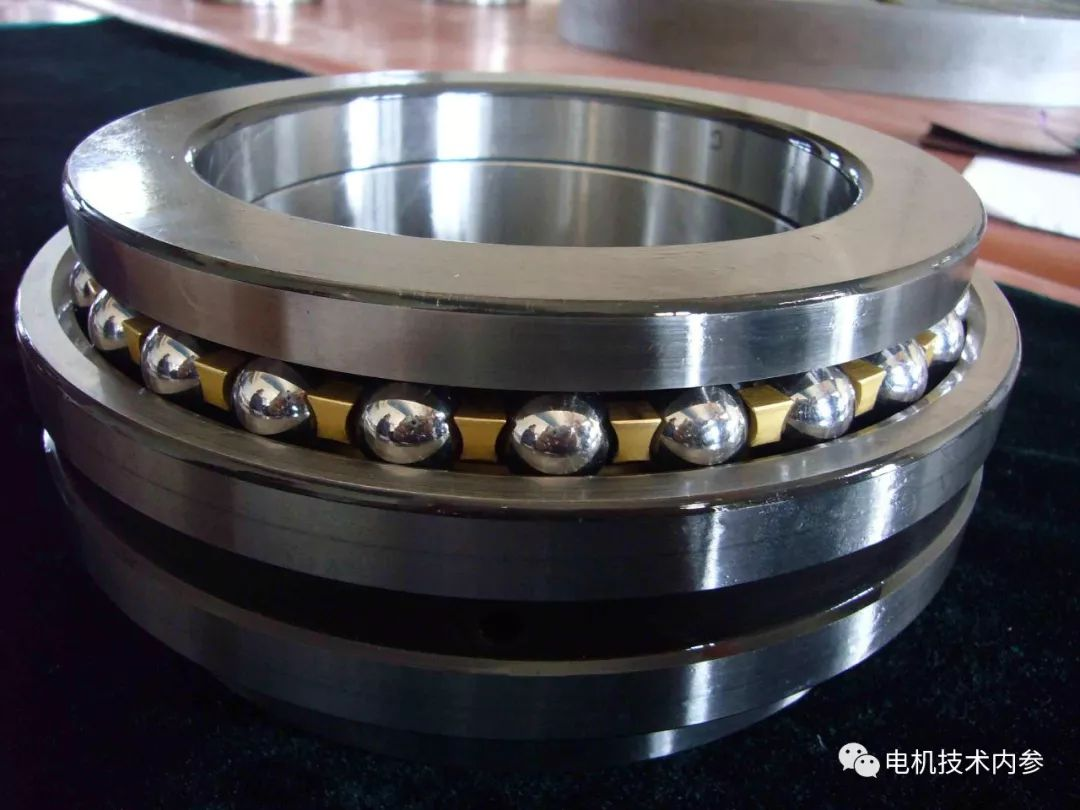

Compared with the horizontal motor, the bearing system of the vertical motor, especially the large-scale vertical motor, has its particularity, and an angular contact ball bearing is used at one end of the motor . Due to the particularity of the structure of angular contact ball bearings, the wrong direction of bearing assembly must not occur, otherwise the bearing will be reimbursed directly. When the bearing is not in place or the axial fit of the bearing itself is misaligned when the motor is running, it may cause abnormal vibration and strange noise of the motor.

Single row angular contact ball bearings are designed for combined loads and can provide high thrust in one direction . Most vertical motors use a set of single row angular contact ball bearings at the non-shaft end for axial forces high enough to exceed those of deep groove ball bearings. In terms of size, it can be interchanged with the single row deep groove bearing of the corresponding motor, avoiding a series of unpredictable problems caused by redesigning the structural parts.

Angular contact ball bearings are also commonly used in gear reducers, pumps, worm gear drives, vertical shafts and machine tool spindles where the axial force is large, and they are often installed in various pairs .

Angular contact ball bearings are used in vertical motors. The purpose is to apply an axial force that is balanced with the weight of the motor rotor to ensure that the axial relative positions of the rotor and the stator are in a balanced state. When the angular contact ball bearing is located below the motor rotor, it is a lifting method; when it is located above the motor rotor, it is a suspension method.

Regardless of the lifting or suspension installation, during the operation of the motor, in addition to the matching relationship of the axial dimension itself, after the motor is powered on, the magnetic force centerline of the stator and the rotor will be aligned spontaneously under the action of electromagnetic force, which may cause the rotor axial Displacement, due to the inevitable accumulative machining errors of parts and the assembly deviation of the whole machine, the actual displacement will lead to axial misalignment of the bearing itself to varying degrees. When the bearing misalignment is serious, the electromagnetic force of spontaneous alignment and the gravity of the rotor become the exciting force of each other, which aggravates the noise and vibration of the bearing.

In the design of the motor, it is necessary to carefully analyze the bearing force, fully consider the possible axial excitation force, and make more fuss about the selection of the motor bearing structure, such as the paired use of angular contact ball bearings, the limit of the axial direction of the bearing, etc. The motor adopts three-bearing structure, the stator and rotor of the motor are properly pre-displaced and other specific measures. Among them, the pre-dislocation size of the stator and rotor of the motor must be moderate, otherwise the result will be counterproductive.

In particular, it should be reminded that during the storage, transportation and testing process of the vertical motor, it is necessary to ensure that the motor is in the correct vertical state, so as to avoid the harmful external force resulting in damage to the bearing .

XINDA

XINDA