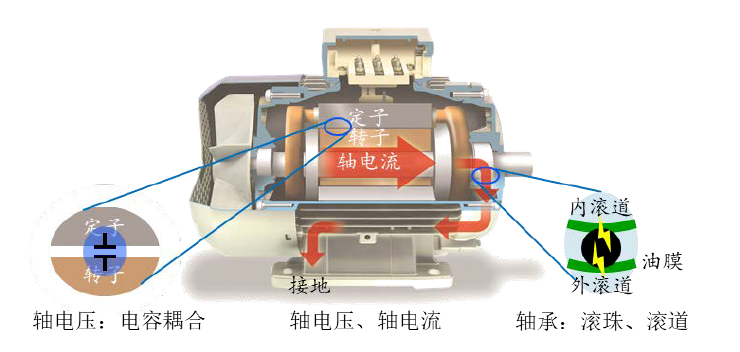

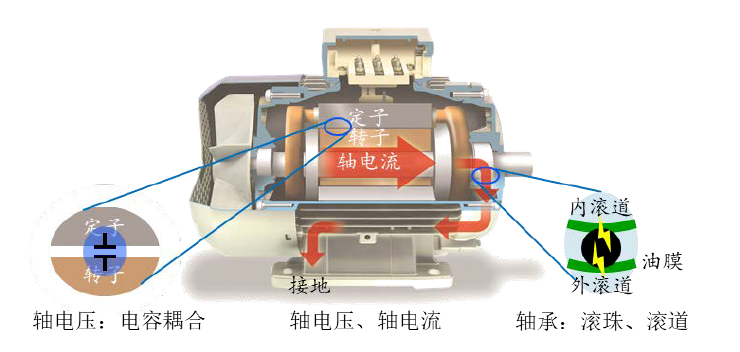

Where does the motor shaft current come from?

The generation of shaft current is due to the shaft voltage and closed loop, and it mostly occurs when the motor has shaft voltage, and the editor reminds that the shaft current will cause great damage to the motor bearing system, which will affect whether the motor bearing system can be used stably It can be said that the shaft current is the "culprit" of the damage to the motor bearing system!

Today, the editor sorts out the data for everyone to analyze why the motor generates shaft voltage/axis current.

First of all, we need to know what is shaft voltage? What is Axial Current?

Shaft Voltage - The potential difference between the ends of the shaft or between the shaft and the bearings.

Shaft current—shaft voltage consists of a loop consisting of journal, oil film, bearing, base and foundation base. When the oil film insulation is damaged, current will be generated in the loop.

The shaft voltage/shaft current event can be simply understood as EDM, and the inner and outer raceways of the bearing are short-circuited instantaneously due to the large discharge current.

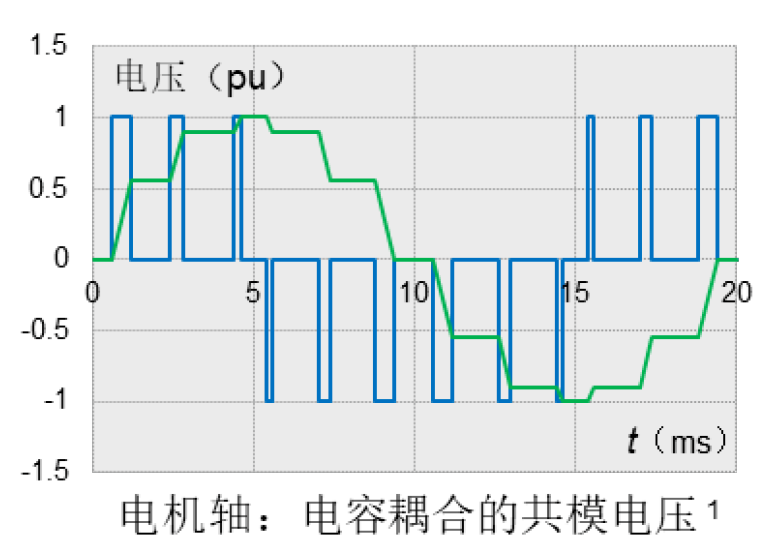

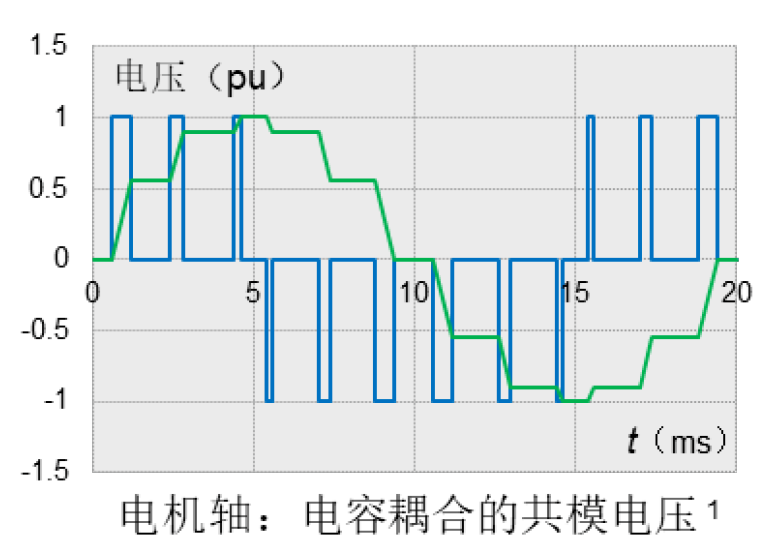

Causes of shaft voltage/shaft current: magnetic imbalance generates shaft voltage; variable frequency power supply generates shaft voltage—zero sequence voltage component (common mode voltage); electrostatic induction generates shaft voltage; external power supply intervenes to generate shaft voltage.

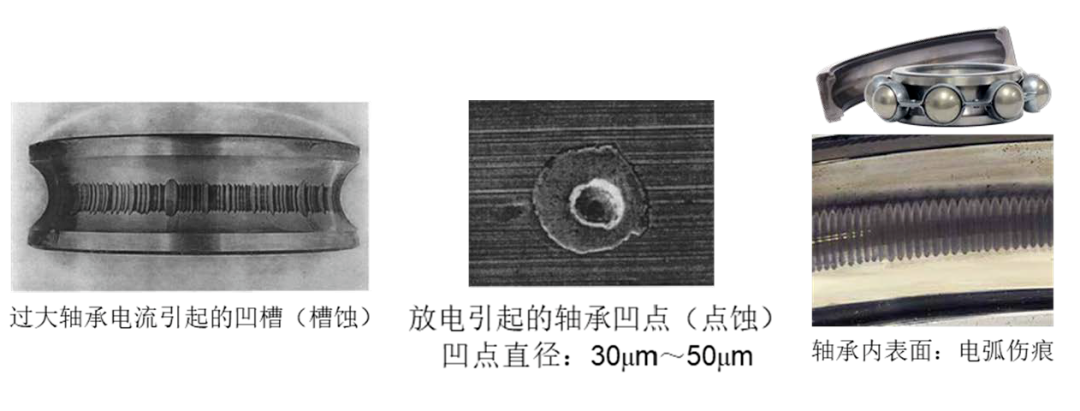

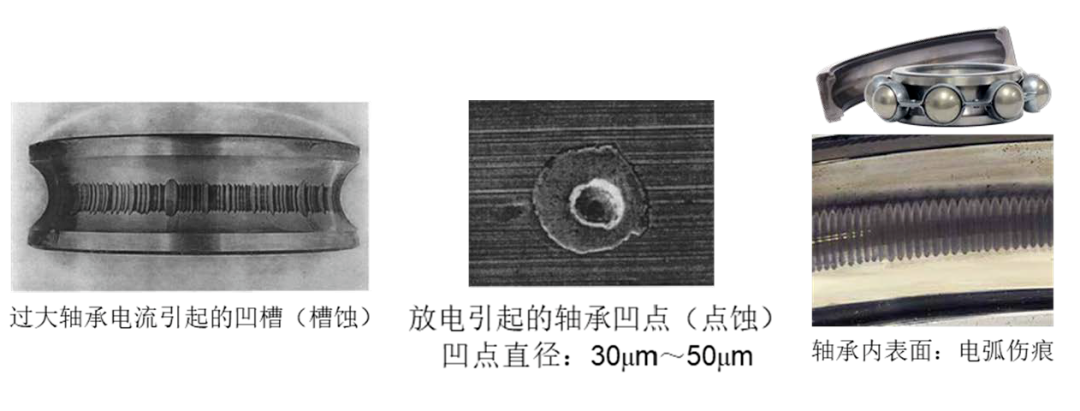

Hazards caused by shaft voltage - be aring damage: due to the point contact between the ball and the inner surface of the raceway, the discharge current density is very high;

aring damage: due to the point contact between the ball and the inner surface of the raceway, the discharge current density is very high;

The instantaneous high temperature of the current may burn the bearing, resulting in electrical corrosion and grooves in the bearing race;

Solutions to Prevent Shaft Voltage Events

Shaft voltage is generally unavoidable, and its damage to the bearing must meet two conditions-the existence of shaft voltage; the shaft current path.

Generally, after the test on site, the following measures can be considered: use isolated cables for the power line between the inverter and the motor, and guide the common mode current into the ground grid; install carbon brushes at the shaft end to reduce the shaft potential; a good grounding system; The bearing seat at the non-shaft extension end is provided with an insulating partition to cut off the shaft current.

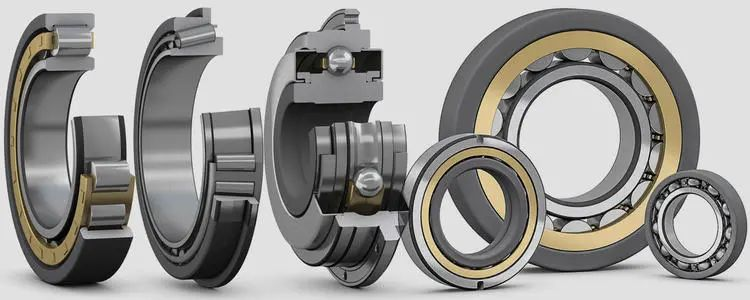

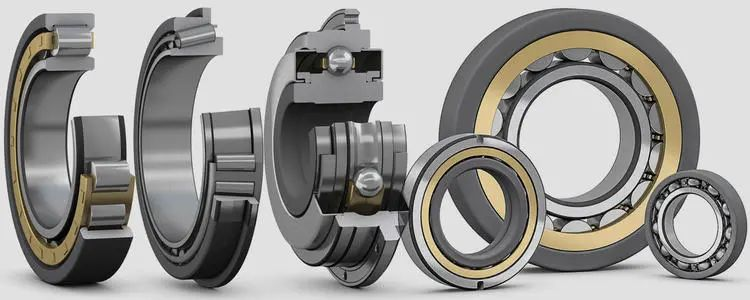

Using insulated bearings: The prevention of shaft voltage is not only about testing and taking measures, but more importantly, from the perspective of predictive maintenance, regularly verify the effectiveness of the measures taken, so as to realize the real protection of bearings, motors and safety.

aring damage: due to the point contact between the ball and the inner surface of the raceway, the discharge current density is very high;

aring damage: due to the point contact between the ball and the inner surface of the raceway, the discharge current density is very high;

XINDA

XINDA