Key control process: Welding of motor windings

Motor winding welding is a key production process in the motor production process, such as the welding of the winding main line and the main line, the welding of the main line and the lead wire, the welding of the copper bar rotor guide bar and the end ring, etc., all of which are directly related to the motor. operational reliability and quality levels . Motors of different types or sizes involve different welding processes, which cannot be simply treated equally. Today Ms. will talk to you about common winding welding methods.

Welding methods can be divided into two main categories: fusion welding and brazing . Fusion welding directly melts the two workpieces together, and the metal at the joint must heated to a molten state to complete the welding. Brazing uses a metal material with a lower melting point than the base metal as the solder, heats the weldment and the solder to a temperature higher than the melting point of the solder and lower than the melting temperature of the base metal, uses the liquid solder to wet the base metal, fills the gap between the joints and The mutual diffusion of the base metals realizes the joint welding. Brazing is mostly used for the welding of motor windings. Although there is also welding, in most cases, brazing is assisted to make up for welding defects .

Common welding methods for motor windings

Silver brazing (gas welding)

This welding method is suitable for occasions with high working current, high temperature and high reliability requirements , and it is also the welding method adopted by most motor manufacturers. Welding equipment is acetylene oxygen torch. When welding, in order to prevent the insulation of the motor wire near the wire end from being scalded, an asbestos rope dipped in water should be wrapped near the wire end. At the same time, it is necessary to prevent solder and flux from flowing into the gap of the coil, which may burn the insulation and cause a short circuit.

Soldering

Soldering is easy to operate and the welding point is firm, so it is the most widely used, but the working temperature is low . Commonly used soldering includes soldering iron soldering and pouring tin. When the number of welding wire ends is large, the method of pouring tin can be used. Due to the limitation of the low melting point of solder tin, it is only used in small motors and motor windings with low temperature rise.

Arc welding

When the wire of the winding is thin, arc welding can be used for welding . The characteristic of arc welding is that it does not require flux, and is fast and convenient. However, when there are many parallel connections and many wire ends, if the operation is not skilled, it is easy to miss welding or not weld firmly.

Copper-aluminum welding Oxygen welding

When soldering, first tin the connecting part of the copper wire or copper lead wire, then twist the scraped aluminum wire on the copper wire, and make the aluminum wire slightly higher than the copper wire. Then apply a layer of aluminum welding powder, and use a neutral flame of gas welding to melt the aluminum wire, so that the aluminum is fused to the top of the copper to form a spherical solder joint. This method is adopted in the welding link between the main line and the lead wire in many motor factories .

Argon arc welding

Argon arc welding is based on the principle of ordinary arc welding, using argon gas to protect metal welding materials, and through high current, the welding materials are melted into a liquid state on the base material to be welded to form a molten pool, so that the metal to be welded and the welding materials reach a A welding technique of metallurgical combination . Due to the continuous supply of argon gas during high-temperature fusion welding, the welding material cannot be in contact with the oxygen in the air, thereby preventing the oxidation of the welding material. This welding plays a good role in the welding quality of the multi-turn winding .

High Frequency Induction Brazing

Induction brazing is to place the metal workpieces to be welded (mostly copper) in the induction coil, pass high-frequency alternating current, generate an induced electromagnetic field, couple on the surface of the workpiece to generate an induced electromotive force, form an induced eddy current on the metal surface, and rely on the metal surface to generate The eddy current generates heat, and welding powder is generally coated on the welding part, and it can be welded when the workpiece reaches the melting temperature of the solder. Induction brazing is currently the cleanest and most environmentally friendly heating welding method in the world.

This type of welding is widely used in copper bar rotors, because the welding operates several solder joints at the same time, the consistency of the process parameters is good, and the deformation of the solder joints is also effective, no matter in terms of work efficiency, reliability and appearance . It is a good process in many aspects , but due to the relatively high cost of equipment and the cost of the corresponding induction coil is also very expensive, so not every manufacturer adopts this welding technology.

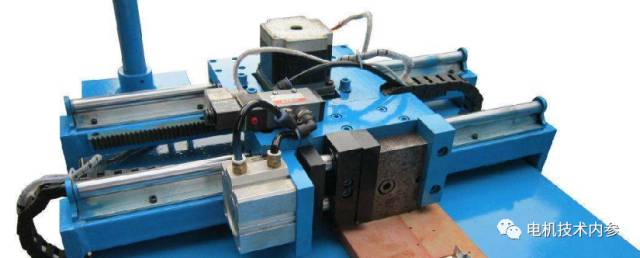

Intermediate frequency induction brazing

Intermediate frequency induction brazing equipment is to assemble the workpieces with cleaned surfaces together in a lap joint type, and place the solder near the joint gap or between the joint gaps.

Intermediate frequency induction brazing equipment can replace outdated heating methods such as oxyacetylene heating, coal oven heating, box-type electric furnace heating, etc., for brazing and quenching heat treatment. It can greatly improve product quality, effectively save electric energy and improve working conditions. When the workpiece and the solder are heated to a temperature slightly higher than the melting point of the solder, the solder melts (the workpiece is not melted), and is sucked into the gap between the solid workpiece by capillary action, and the liquid solder and the metal of the workpiece diffuse and dissolve. After cooling, a brazed joint is formed. The characteristics of intermediate frequency induction brazing equipment: 1. Since the principle of intermediate frequency induction heating is electromagnetic induction, the heat is generated by the workpiece itself. This heating method has fast heating metal The surface is only slightly depigmented, and light buffing returns the surface to a mirror-like luster, effectively achieving consistent material properties. 2. Uniform heating, high temperature control precision Uniform heating ensures small temperature difference between the heating core and surface. The temperature can be precisely controlled through the temperature control system to ensure product repeatability .

Intermediate frequency induction brazing is widely used in the welding of bare copper rotor guide bars. This welding method has strict requirements on guide bar cutting, forming and related headgear shapes, otherwise the welding effect will be greatly reduced .

Based on the above information, each motor manufacturer should make a comprehensive evaluation based on its own equipment characteristics and product characteristics, but the reliability of welding quality is the key technology for manufacturing.

XINDA

XINDA