Ten billion market linear motor working principle and market, prospect analysis

Linear motor is an important branch of servo system. Compared with rotary motors, linear motors do not require intermediate transmission links during motion, so linear motors have certain advantages in accuracy, speed and acceleration compared to rotary motors. The disadvantages applied to Z-axis motion also affect its market size to a certain extent. At present, the main application fields of linear motors include maglev trains, 3C, semiconductors and lithium batteries . With the increase of downstream application scenarios, the gradual maturity of technology and the continuous decline of prices, linear motors are expected to become a more cost-effective choice. In 2025 The annual market size is expected to reach 6 billion yuan, and it will become a tens of billions market in the future.

1. The structure of the linear motor

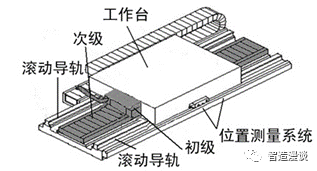

Servo motors can be broadly divided into two categories: rotary servo motors and linear servo motors. Traditional servo motors are generally rotary motors. Linear motors are also called linear motors, linear motors, linear motors, etc., and their motion is along a straight line, unlike rotary motors that require screw drives. The linear motor is mainly composed of a stator (primary), a mover (secondary), a sliding guide rail, a position measurement system and a workbench, as follows:

Figure 1 Structure of linear motor

The stator of a linear motor is usually composed of a coil winding and an iron core tooth yoke structure/epoxy resin tooth yoke structure (the difference between an iron core motor and an iron core motor); the mover of a linear motor is usually composed of a yoke (metal Plate), permanent magnet and epoxy resin protection structure, after the stator wiring is energized, a magnetic field will be generated between the stator and the mover, and then electromagnetic thrust will be generated to realize the linear motion of the moving parts.

Figure 2 Motion diagram of linear motor

Rolling guides are usually composed of linear guides, linear motion sliders and rolling bearings, which are used to support and guide moving parts to move smoothly in a given direction for reciprocating linear motion.

The position measurement system is usually composed of a magnetic scale/grating scale and a reading head, which is used to detect and feed back the position and speed of moving parts, forming a fully closed-loop control, and its accuracy largely determines the positioning accuracy of the entire system.

The working table is composed of a drag table and a base, the stator is fixed on it, and the mover drives it to move freely, and the function is to drive the load to quickly translate linearly and position accurately.

Second, the basic working principle of linear motor

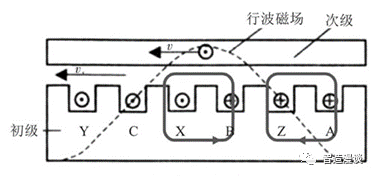

The working principle of the linear motor is the same as that of the rotary motor. After the stator winding is fed with three-phase alternating current, according to the magnetic effect of the current, the electrified coil will generate a magnetic field. This magnetic field and the magnetic field generated by the mover permanent magnet will synthesize a sine wave magnetic field moving along a straight line, that is, a traveling wave magnetic field. The moving direction of the magnetic field is determined by the phase sequence of the three-phase alternating current.

According to Lenz's law, under the cutting of the traveling wave magnetic field, the metal plate of the mover will induce electromotive force and generate a current, which will interact with the traveling wave magnetic field to generate electromagnetic thrust, driving the mover to move in a straight line along the direction of the traveling wave magnetic field , or use the reaction force to drive the stator to move in the opposite direction.

Figure 3 Basic working principle of rotary motor and linear motor

Fig. 4 Motion diagram of working principle of linear motor

3. Advantages and disadvantages of linear motors compared to rotary motors

When the rotary motor is actually used in linear motion, it needs a series of intermediate transmission links , such as couplings, leadscrews, etc. These parts will produce elastic deformation when the servo system completes startup, acceleration and deceleration, reverse rotation, parking and other actions. Friction, backlash, etc., cause movement lag and many nonlinear errors, resulting in power consumption. In addition, these intermediate links also increase the inertial mass of the system, which affects the rapid response to motion commands, and the lead screw is a slender rod, which will deform under the action of force and heat, which will affect the processing accuracy.

The birth of the linear motor has canceled all the intermediate transmission links from the motor to the workbench. When doing linear motion, there is no need to convert the rotary motion into a linear motion additional device, which simplifies the motor structure and realizes "direct transmission", that is, " Zero transmission" eliminates various errors caused by intermediate links and reduces power loss. Therefore, the performance of linear motors has performance indicators and advantages such as high precision, high speed, and high acceleration that cannot be achieved by the original rotary motor drive method:

1. High-speed response . Because the linear motor cancels some mechanical transmission parts (such as lead screws, etc.) with large response time constants, the dynamic response performance of the entire closed-loop control system is greatly improved.

2. Accuracy , the linear motor cancels the transmission gap and error generated by the mechanical mechanism such as the lead screw, and reduces the tracking error caused by the lag of the transmission system during the interpolation movement.

3. The speed is fast and the acceleration and deceleration process is short . Due to the high-speed response of "zero transmission", the acceleration and deceleration process of the linear motor is greatly shortened, so as to achieve high speed when starting, and stop precisely when running at high speed.

Although linear motors are superior to rotary motors in terms of speed, acceleration, and accuracy, they also have certain disadvantages compared with rotary motors in terms of price and installation requirements:

1. The price is high . The cost of the grating scale, the core component of the linear motor, remains high, making the price of the linear motor higher than that of the rotary motor.

2. The installation requirements are high . The linear motor is a high-precision product, and its installation process will also affect its positioning accuracy. The installation work requires a certain technical background.

3. There is generally no brake device . If the linear motor is installed vertically, it will fall vertically under the influence of gravity when there is a sudden power failure or failure. Therefore, linear motors are generally used for plane motion, but cannot be used for Z-axis motion in a wide range.

4. Application of linear motor

01

Linear motor market prospect

With the rapid development of China's industrial field, the requirements for product quality are getting higher and higher, and the requirements for machine performance are gradually increasing, especially in CNC machine tools, semiconductor integrated equipment and other machinery. In the future, CNC machine tools will adopt linear The proportion of motor feed drive will gradually increase, and the industrialization prospect of the linear motor industry is self-evident.

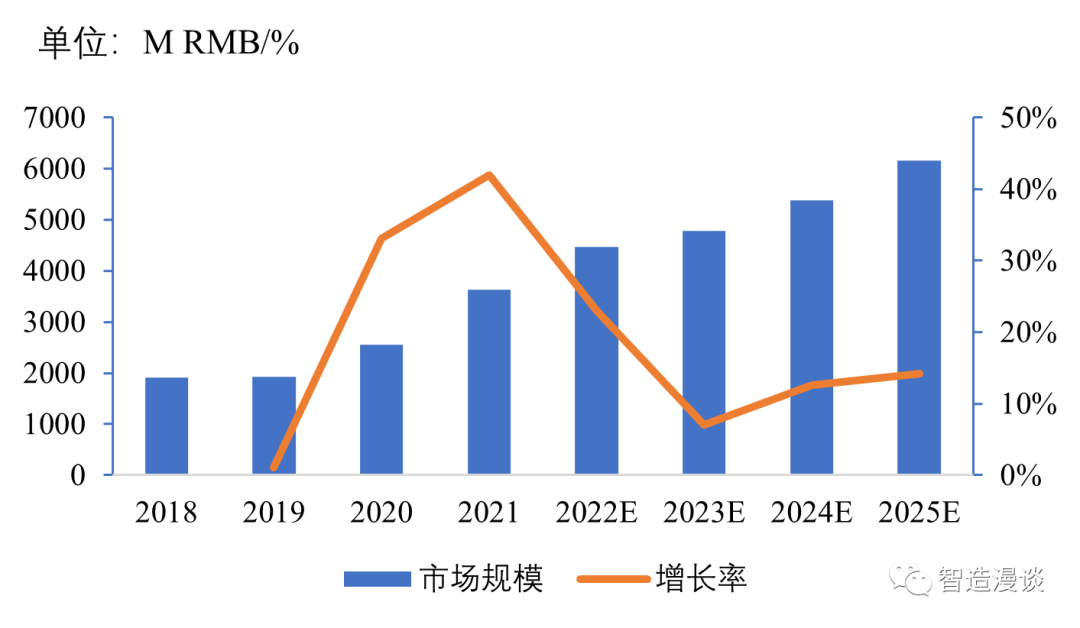

According to the "2021 Linear Motor Market Data Interpretation Report", the OEM (Original Equipment Manufacturer) market is generally sluggish in 2019, and the growth of motion control products including linear motors is generally slow or even declining. Despite the impact of the epidemic in 2020 and 2021, the demand for multiple downstream industries where linear motors are more widely used is exploding and suppliers are actively expanding, so the linear motor market continues to grow at a high speed.

In terms of downstream industry applications, on the one hand, 3C, semiconductors, lithium batteries, laser processing machine tools and other industries will have a high boom in 2021, and the demand for automation products is generally strong; on the other hand, there are more and more models using linear motors in the industry. More and more, especially for models with higher requirements on precision, speed, space, and output, linear motors can better meet customer performance requirements than traditional screw + rotary servo motors, so the trend of product substitution is strengthening.

On the supplier side, linear motor technology is becoming more and more mature. A large number of domestic brand suppliers have entered the market and actively expanded their customers. They can flexibly provide customers with customized products/solutions that meet specific application requirements, which is also an important factor for market growth. reason.

In terms of price, the price of linear motors has also been declining in the past two years, and the acceptance of customers is getting higher and higher, which promotes the rapid growth of the market.

Therefore, after two consecutive years of rapid growth, combined with the cyclical characteristics of the automation market, it is expected that the market will have a slowing growth trend in the next two years, and will show a fluctuating growth overall in the next five years. It is estimated that the linear motor market size in 2025 will be reached 6 billion yuan.

Figure 5 2018-2025 analysis of the overall market size of linear motors

Figure 6 Market Shares of Linear Motor Suppliers in 2020 and 2021

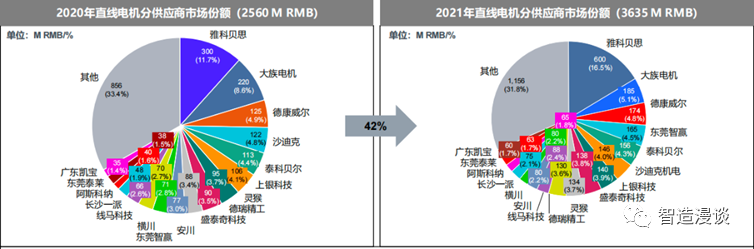

According to the "2021 Linear Motor Market Data Interpretation Report", compared with 2020, the proportion of domestic brands in the linear motor market will gradually increase in 2021 , and the market share and ranking of foreign-funded manufacturers except Akribes will decline. , while the ranking of domestic brands has changed greatly, the number of companies with sales of more than 100 million has increased, and many small manufacturers have poured in.

02

Applications of linear motors

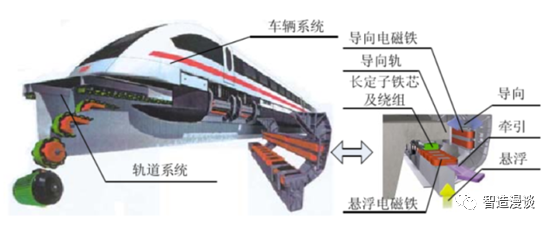

Due to the performance advantages of linear motors in terms of high precision, high speed, and high acceleration, linear motors are mainly used in occasions with high precision or high cycle requirements . High-speed maglev trains are the most typical example of practical applications of linear motors.

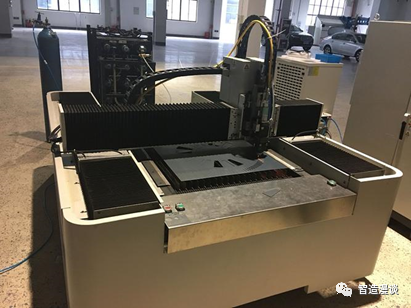

Equipment companies that choose to develop linear motors adopt the method of maximizing strengths and avoiding weaknesses . One is to apply linear motors to occasions that face mass production, have many positioning movements, and frequently change directions, such as auto parts processing machine tools, rapid prototyping machines, and semiconductor production machines. ; The second is for occasions with low load and large process range, such as electric machine tools, plasma cutting machines, water jetting machines, etc.

From the perspective of the application industry , linear motors are widely used in 3C, semiconductors, lithium batteries, laser processing machine tools and other fields, as well as in medical (life science, medical equipment, etc.), aviation (flight control systems, pilot feedback systems, etc.) and other fields. Applications of linear motors can be seen.

Figure 7 Application of linear motors on maglev trains

igure 8 Application of linear motor CNC machine tools (auto parts processing machine tools, automatic feeding machine tools, etc.)

Figure 9 Application of Ring Linear Motor Maglev Conveyor Line System

Figure 10 Application of linear motor in laser cutting

Figure 11 Linear motors used in medical equipment

XINDA

XINDA