When choosing a high-quality motor, you must master 6 key points

How can we buy genuine motors at a fair price, and how to distinguish the quality of motors?

There are many three-phase asynchronous motor manufacturers, and the quality and price are also different. Although my country has already formulated the technical standards for motor production and design, many companies have adjusted the motor design according to the market segmentation needs, and thus formed the motor in the market. Performance varies.

The three-phase asynchronous motor is a product with very mature technology, and the production threshold is also low. In areas with developed industrial chains, there are many small workshop-style motor factories, but to achieve excellent performance and stable quality of the motor, it must Only a large-scale motor factory can be guaranteed.

Silicon steel sheets are an important part of the motor, and together with copper wires account for the main cost of the motor. Silicon copper sheets are divided into cold-rolled steel sheets and hot-rolled steel sheets. The country has long advocated the abandonment of hot-rolled sheets. The performance of cold-rolled sheets can be reflected in the brand name. Generally, DW800, DW600, DW470, etc. are used. Ordinary asynchronous motors generally use DW800. Some companies use strip steel to manufacture motors, and the performance is significantly different.

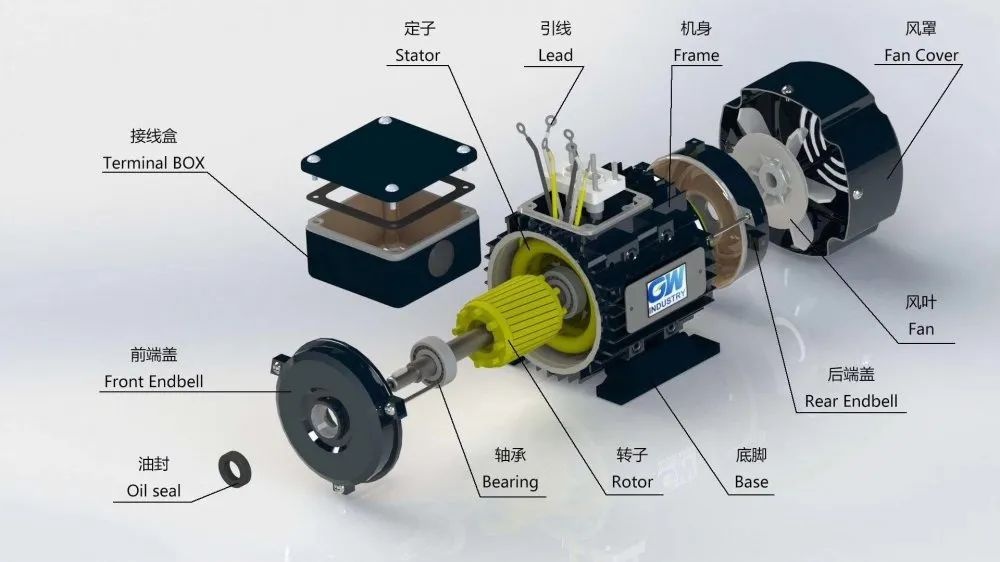

Both the stator and rotor of the motor are die-cast from silicon steel sheets. The length and tightness of the die-casting have a great influence on the performance of the motor. The longer the die-casting length of the iron core is, the tighter it is, the better the power performance will be. Some companies reduce the cost by shortening the length of the iron core or reducing the price of the silicon steel sheet grade, and the price of the motor is lower.

The full rate of the copper wire slot refers to the amount of copper wire used. The longer the iron core, the more copper wire will be used at the same time. The enterprise reduces the slot shape of the stator without changing the length of the iron core, so as to reduce the amount of copper wire and reduce the cost.

The bearing is the carrier that withstands the high-speed operation of the motor rotor. The quality of the bearing will affect the running noise and heat of the motor.

The casing is responsible for the vibration and heat dissipation of the motor during operation. Calculated by weight, the heavier the casing, the greater the strength. Of course, the appearance design of the casing and the appearance of die-casting are important factors that affect the price of the casing.

Including machining accuracy of parts, rotor die-casting process, assembly process, insulation dipping paint, etc., will affect the performance and quality stability of the motor. The production process of large-scale manufacturers is relatively stricter and the quality is more guaranteed.

Generally speaking, the motor is basically a product that you get what you pay for. The quality of the motor with a large price difference will definitely be different. It mainly depends on whether the quality and price of the motor can meet the customer's use requirements. Suitable for different market segments.

XINDA

XINDA