The inner workings of a car motor

The motor uses the energized coil to generate a rotating magnetic field and acts on the rotor to form a magnetoelectric power rotating torque. According to the different power sources used, it is divided into DC motors and AC motors. Most of the motors in the power system are AC motors, which can be synchronous motors or asynchronous motors. . It is mainly composed of a stator and a rotor. The direction of the energized wire in the magnetic field is related to the direction of the current and the direction of the magnetic field line. The working principle is that the magnetic field acts on the current to make the motor rotate.

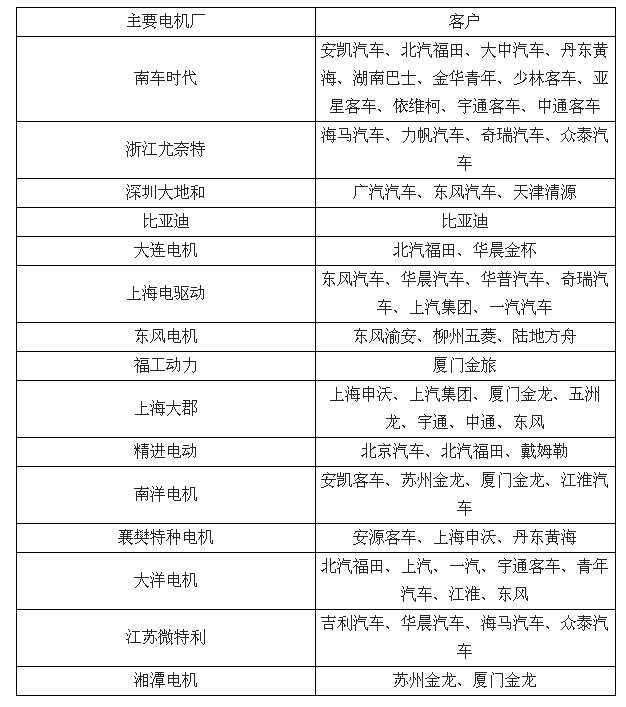

In the market environment, the development momentum of the overseas electric vehicle motor and electronic control industry is relatively clear. There are two main routes: one is the in-house route in which vehicle companies represented by Toyota use self-developed supporting parts; the other is the in-house route. Car manufacturers cooperate with powerful electronic control manufacturers to form a stable supply chain. Foreign new energy vehicles started early in all aspects. Professional parts companies have obvious advantages in technology and high market concentration. Well-known parts companies such as Bosch, Continental, Magna, Hyundai Mobis and ZF and so on, monopolizing the vast majority of the market share. The relationship between some motor factories and the complete vehicle is as follows:

Several common motor starting methods include: full-voltage direct starting, auto-decompression starting, y-delta starting, soft starter, and frequency converter.

Full-voltage direct starting: In the case that full-voltage direct starting is allowed in both power grid capacity and load, full-voltage direct starting can be considered. The advantage is that it is easy to operate and control, simple to maintain, and more economical. It is mainly used for starting small-power motors. From the point of view of saving electric energy, this method should not be used for motors larger than 11kw.

Auto decompression start: The multi-tap decompression of the autotransformer can not only meet the needs of different loads, but also obtain a larger starting torque. It is a decompression often used to start large-capacity motors. Starting method. Its biggest advantage is that the starting torque is large. When its winding tap is at 80%, the starting torque can reach 64% of the direct starting. And the starting torque can be adjusted by the tap. It is still widely used today.

y-delta starting: For squirrel-cage asynchronous motors with delta-connected stator windings in normal operation, the starting current can be reduced if the stator windings are connected in a star shape when starting, and then connected in a delta after starting. , to reduce its impact on the grid. Such a starting method is called star-delta decompression starting, or simply star-delta starting (y-delta starting).

Inverter: Inverter is a motor control device with the highest technical content, the most complete control function and the best control effect in the field of modern motor control. It adjusts the speed and torque of the motor by changing the frequency of the power grid. Because it involves power electronic technology and microcomputer technology, the cost is high and the requirements for maintenance technicians are also high, so it is mainly used in fields that require speed regulation and high speed control requirements.

There are many speed regulation methods for electric motors, which can adapt to the requirements of different production machinery speed changes. Generally, when the motor speed is adjusted, its output power will change with the speed. From the perspective of energy consumption, speed regulation can be roughly divided into two types:

① Keep the input power unchanged. By changing the energy consumption of the speed control device, the output power is adjusted to adjust the speed of the motor.

②Control the input power of the motor to adjust the speed of the motor. Motors, electric motors, brake motors, variable frequency motors, speed-regulated motors, three-phase asynchronous motors, high-voltage motors, multi-speed motors, two-speed motors and explosion-proof motors.

Here are a few sets of electric motor diagrams:

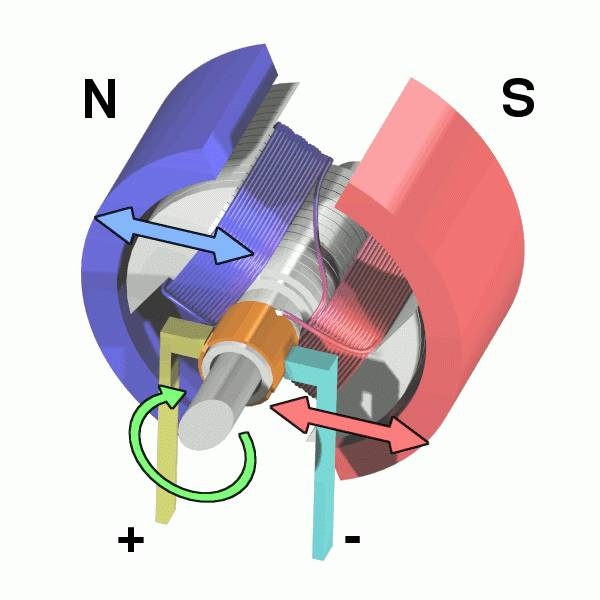

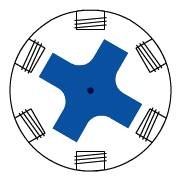

Permanent magnet motor

DC motor

Quantum magneto

Single Phase Induction Motor

How a Stepper Motor Works

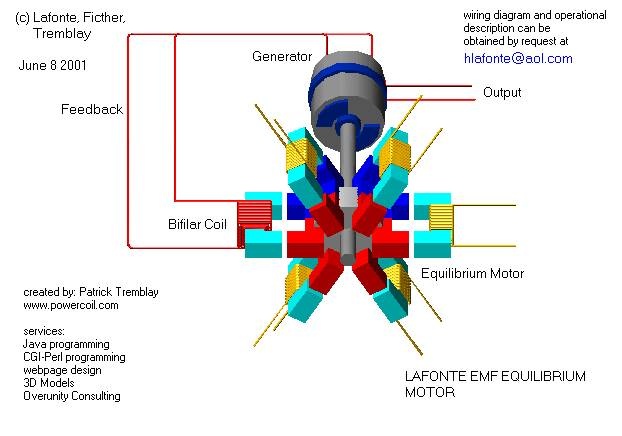

balance motor

The principle of generating electric current

Three-phase stator

Motor section

electric motor

As a new industry, the accumulation of technology and experience is particularly important for new energy vehicle motors. If new entrants in the industry start from research and development, to supporting the supply of complete vehicles, it will take at least three years.

XINDA

XINDA