Introduction to the advantages and disadvantages of flat wire motors

Introduction to the advantages and disadvantages of flat wire motors, application analysis and development trend prospects

At present, flat wire motors are more concerned in China, but their applications are relatively small , mainly because the development time of the new energy market is relatively short, and the main market share is concentrated in the mini-passenger vehicle market.

There are already mature flat wire motor products used in new energy vehicles abroad, especially Japanese and European and American companies, Toyota and GM have adopted flat wire motors.

The most representative ones are Chevrolet VOLT (Remy Motor) and Toyota Prius (Japan Denso), both of which use oil cooling solutions.

In addition to foreign suppliers such as Remy, Denso, and Hitachi, domestic suppliers with stable shipments mainly include Huayu Electric, Songzheng Electric, and Founder Electric, which is about to be put into production.

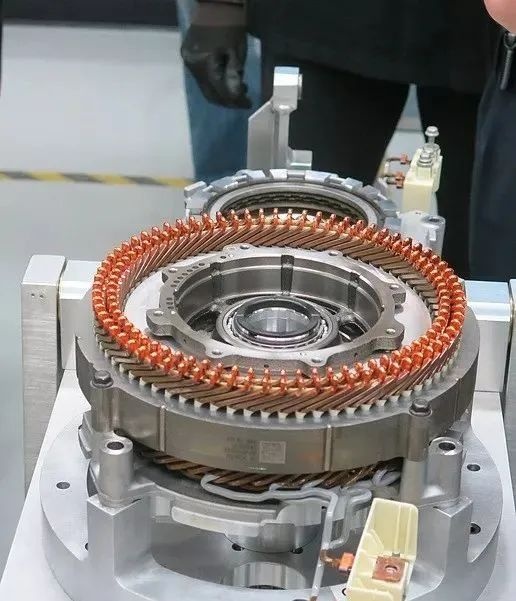

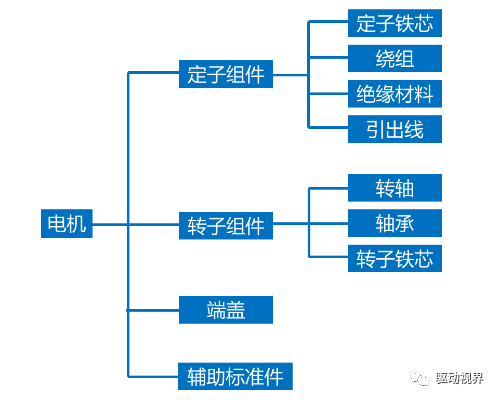

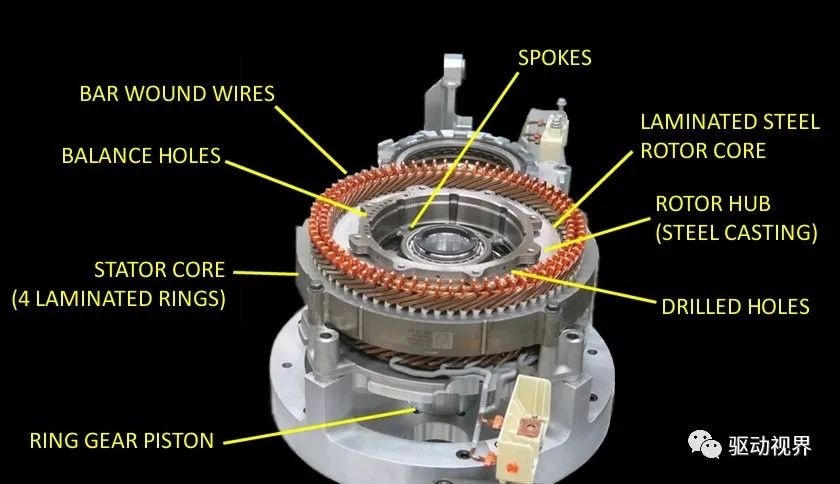

The drive motor is mainly composed of stator components, rotor components, end covers and auxiliary standard parts, and the stator windings also include iron cores, copper wire windings, insulating materials, etc.

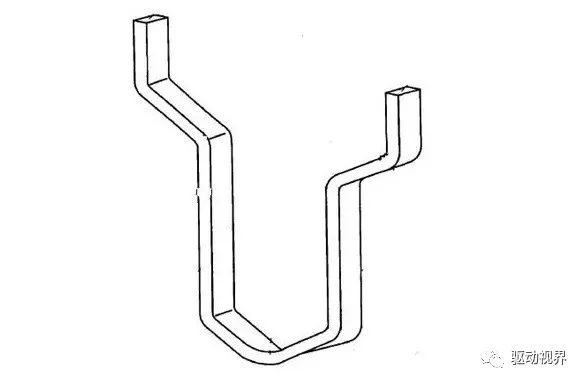

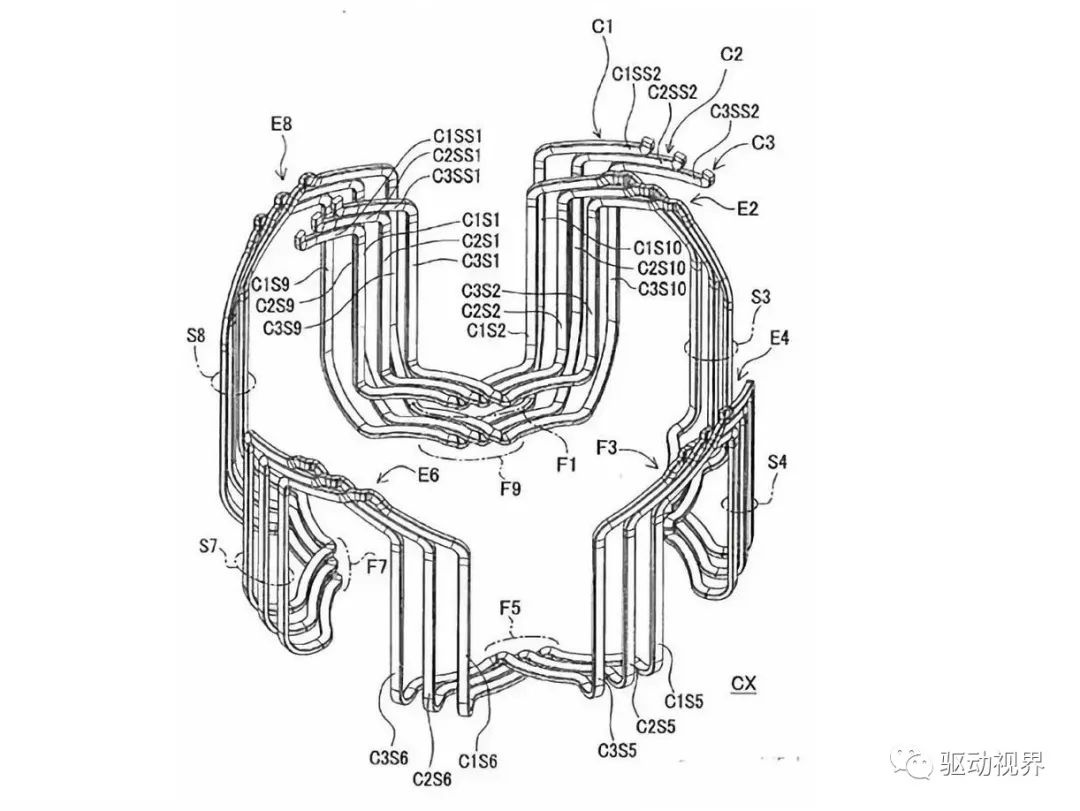

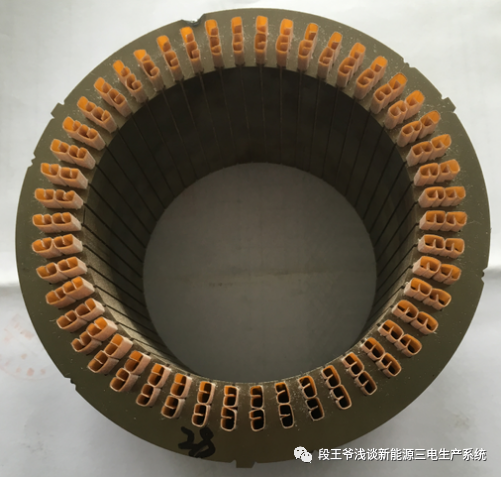

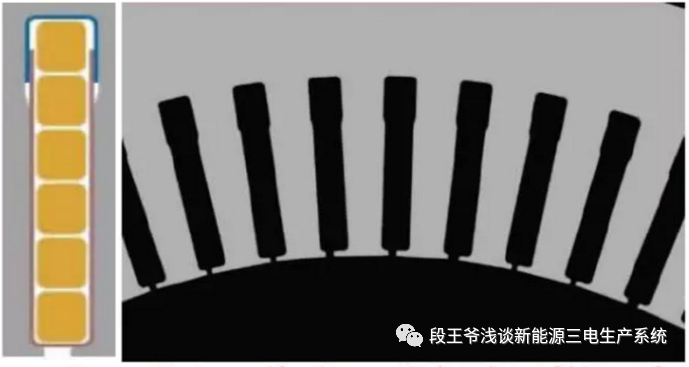

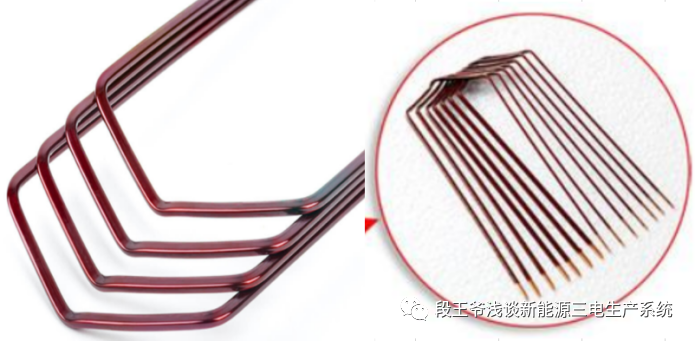

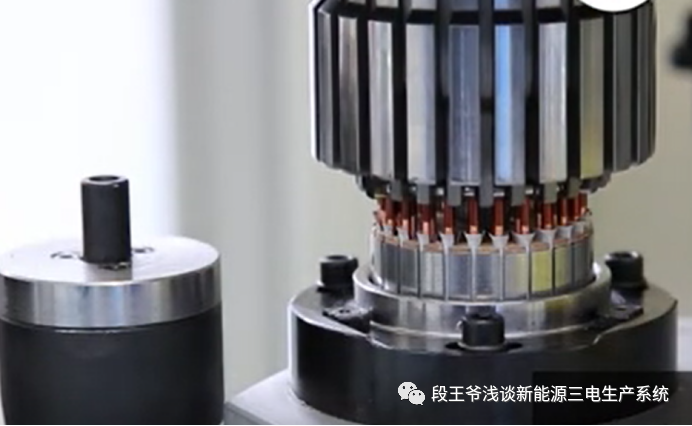

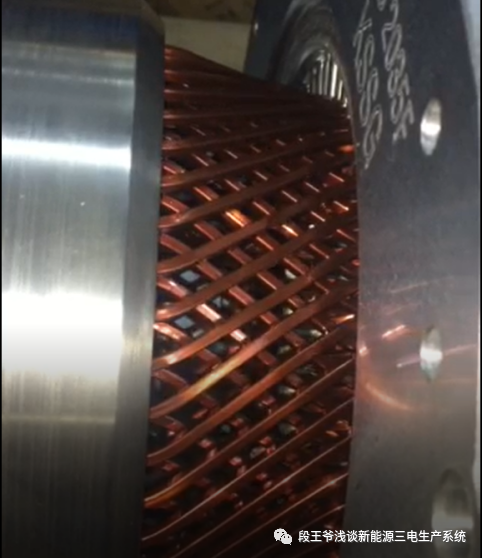

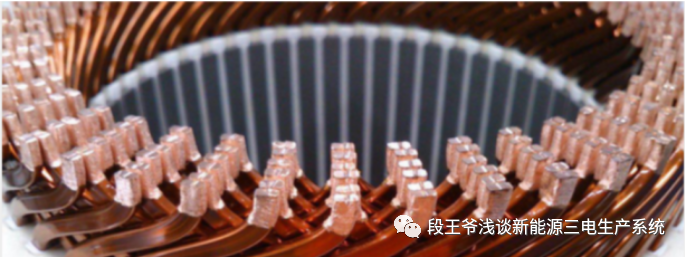

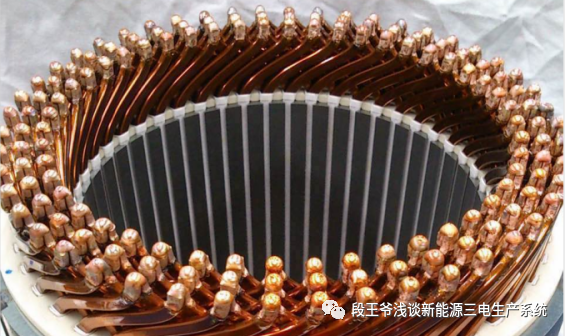

As the name suggests, the flat wire motor uses flat copper wire in the stator winding. First, the winding is shaped like a hairpin, penetrated into the stator slot, and then the end of the hairpin is welded at the other end.

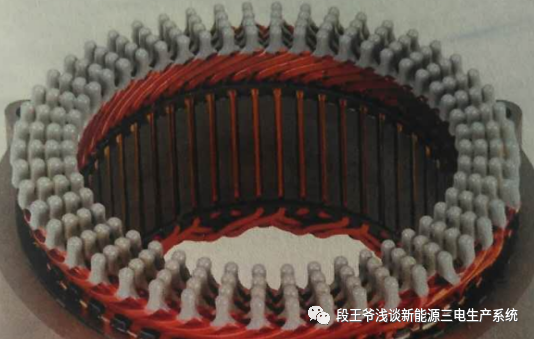

▲Segmented hairpin winding

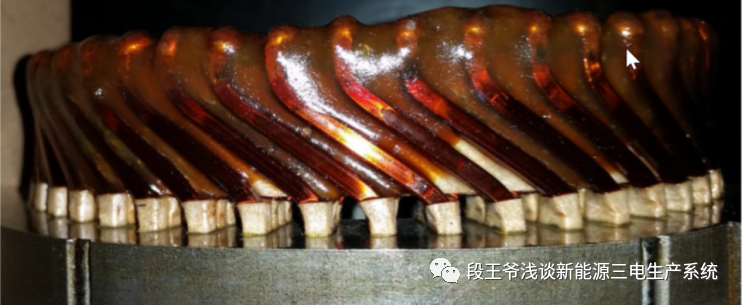

▲Continuous hairpin winding

Advantages of flat wire motors

Advantage 1: The same power, smaller volume, less material, lower cost, or the same volume, the slot full rate is increased, and the power density is increased. The round wire becomes a flat wire. In theory, under the premise of the same space, the flat wire motor can achieve a 70% slot full rate, and the filled copper can be increased by 20-30% to generate a stronger magnetic field strength. In a way that equates to a 20-30% increase in power.

Advantage 2: Better temperature performance. The internal gap is reduced, the contact area between the flat wire and the flat wire is large, and the heat dissipation and heat conduction are better; the contact between the winding and the core slot is better, and the heat conduction is better; and the motor is very sensitive to heat dissipation and temperature, and the heat dissipation Better, performance will improve. Some people have simulated the temperature field and found that the temperature rise of the flat copper wire motor with the same design is 10% lower than that of the round copper wire motor.

Advantage 3: Lower electromagnetic noise. The wire of the flat wire motor has relatively large stress and high rigidity, and the armature has better rigidity, which has a suppressing effect on the armature noise; a relatively small notch size can be used to effectively reduce the cogging torque and further reduce the electromagnetic noise of the motor .

Advantage 4: The end is short, saving copper and improving efficiency. For traditional round wire motors, due to process problems, the ends of the motors are generally left relatively long, otherwise the copper wire will be easily damaged during the process. For flat wire motors, because the wires are all hard wires, the ends can be made smaller during processing . Compared with the round wire motors, the end size is reduced by 20%, and the space is further reduced, which can reduce the volume of the system. Further reduction, miniaturization and light weight are realized.

Advantage 5: The highest efficiency point of the flat wire motor is not necessarily much higher than that of the round wire, but the high efficiency area can be further widened.

Disadvantages of flat wire motors

Disadvantage 1: High-speed skin effect. The high power density of new energy vehicles requires a high speed. In the past, it was 10,000 or even 12,000 rpm, but now it is done in the direction of 16,000 or even 20,000. There needs to be some good ways to solve it in the process of motor design, which is a bad place.

Disadvantage 2: The copper wire requirements are high. There are many domestic manufacturers of round wire motor copper wires, and the quality can be very good. There are not many manufacturers that can make flat wire motors better, and the requirements are relatively high, and everyone needs to work together to solve the materials.

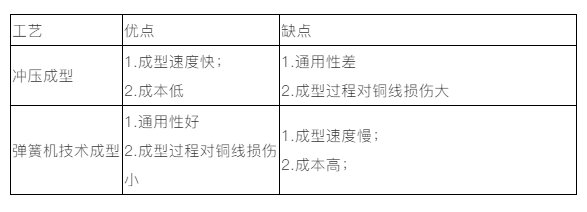

Disadvantage 3: The flat wire has many processing procedures, high equipment precision requirements, and large initial investment, because if its precision is not high, the reliability and consistency of the product will be relatively poor. Car companies are also worried about the reliability and stability of quality.

Disadvantage 4: Serialized design is difficult. In order to reduce the cost of the motor, it is best to serialize it. The serialized design is the place where the current flat wire motor is inferior to the round wire motor.

Disadvantage 5: There are too many patent barriers. At present, the flat wire motor patents are mainly in European, American and Japanese companies. Chinese companies have few patents. We have a patent layout, but it is not satisfactory.

Disadvantage 6: The flat wire forming requirements are high and the processing is difficult. Because copper wire has a certain elasticity, it is necessary to leave a deformation allowance in the design.

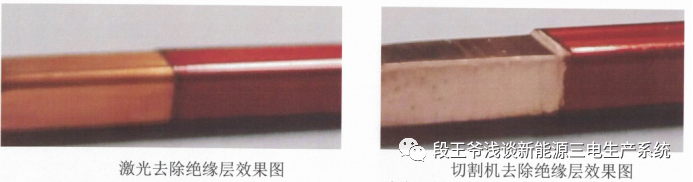

Disadvantage 7: The insulating coating will shrink and deform after drying. If it is a round wire, the shrinkage will be more uniform, while the flat wire is prone to damage, resulting in a much lower yield rate of the flat wire in actual processing. .

Flat wire motor production process

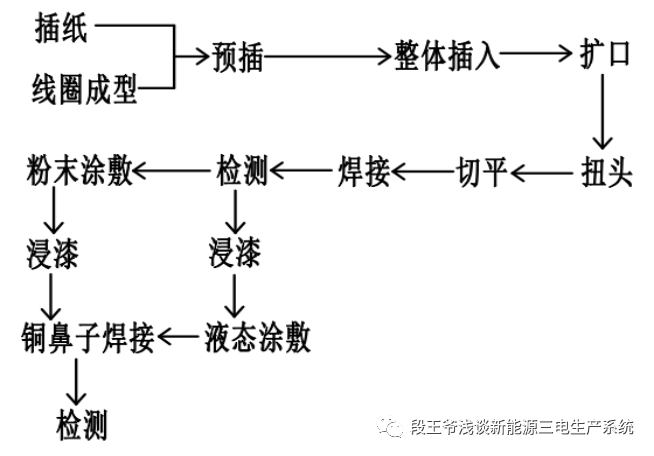

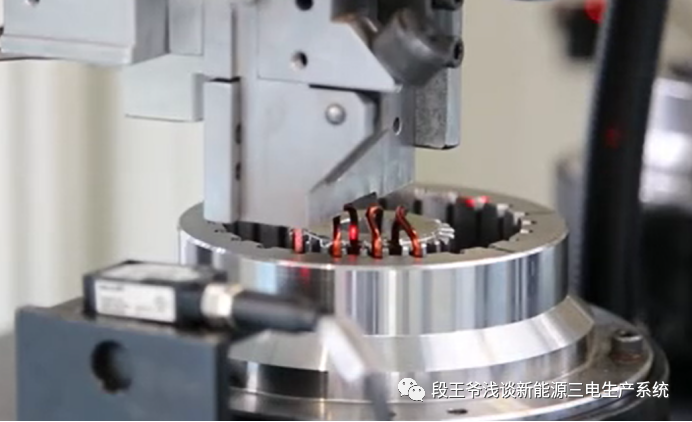

The main production process of the hairpin motor stator is wire forming, paper forming and paper insertion. These two processes are carried out simultaneously. Enter the wire insertion process of the stator, then twist the wire, and then perform the welding process after the twisting is completed. After the welding is completed, the basic process of the stator of the motor is completed, followed by coating, and then performance testing and verification. This is the basic flow with lots of details in between.

Flat wire motor production process: slot paper → manufacturing hairpin → hairpin threading → end ring shaping → end ring welding → star point → insulation treatment at welding

Application of flat wire motor

In the long run, miniaturization and high speed will be the main development trends of new energy vehicle motors, and miniaturization will inevitably require a substantial increase in motor power density. From the perspective of technical requirements, the "Thirteenth Five-Year Plan" proposes new energy vehicles. The peak power density of the drive motor should reach 4kW/kg, and the current data only reaches 3.2-3.3kW/kg.

Flat wire winding motors have been successfully applied in foreign manufacturers such as Chevrolet volt2, Nissan electric vehicles, Toyota's fourth-generation Prius, etc. It is an inevitable trend in the development of my country's next-generation new energy vehicle motors. Currently, BYD, SAIC, BAIC, and Jingjin New Energy are in Internal OEMs and motor manufacturers have carried out corresponding research.

Before 2020, the replacement of flat wire motors to circular motors is still not obvious enough. Thanks to the advantages of the small size of the flat wire motor, the flat wire motor will be preferentially applied in large-scale hybrid vehicles, especially plug-in vehicles. However, due to policy and market factors in China, the proportion of plug-in models is relatively low. In the pure electric field, only one model of SAIC Roewe ERX5 is equipped with a flat wire motor, which is rarely used.

Further reading:

01 Features of flat wire motor

02Flat wire motor processing technology

when selecting powder materials, the process sequence is to apply first and then dip paint;

| select liquid materials, the process sequence is to dip paint first and then coat;

the specific process requirements shall be carried out according to the requirements of materials .

XINDA

XINDA