Heat shrink sleeve technology greatly improves ability to hold and protect brushless motor magnet

In recent years, brushless motors have been smaller in size, can provide the same torque as ferrite, consume less power, have higher speeds, require less maintenance, better heat dissipation, and can be overloaded, so in The use of electric motors is growing exponentially. One of the most critical problems of this surface permanent magnet motor is the complexity of fixing the NdFeB magnets to the rotor, the fragility of NdFeB magnets cannot be welded to the rotor, and the permanent magnets will suffer irreversible losses at high temperatures Magnetic flux (Curie point). To solve this problem, Politobes worked with DuPont to develop a special helically wound tube made of heat-shrinkable polyester (Mylar HS) that enables automatic fixation of permanent magnets, reducing assembly of these cost of the motor.

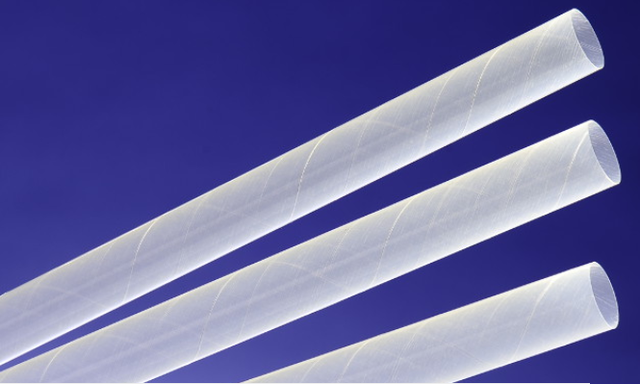

Multilayer heat shrink tubing with high mechanical resistance and high thermal coefficient for securing and protecting brushless motor rotors, balancing all types of centrifugal forces exerted on permanent magnets. There is no danger of cracking or damaging the precision permanent magnets during assembly. It has the advantage of a perfect bond even at the edges of the rotor. In addition, the glass fiber inside the heat shrinkable sleeve also has extremely high mechanical strength and temperature resistance, and the temperature used for heat shrinkage is much lower than the Curie point, which will not reduce the magnetic flux of the magnet.

Insert the heat shrink sleeve onto the rotor, the magnets are in place, and heat shrink (by using a much lower temperature than the Curie point and avoiding any risk of flux loss), a firm adhesion is obtained even at high rpm . It is also resistant to thermal shock when the motor runs for extended periods of time (up to 180°C). Eddy current losses are avoided compared to very expensive metal rotor sleeves, which reduce motor efficiency and can cause the motor to overheat. Due to its limited thickness range between 0.19-0.35 mm, the sleeve ensures optimum permanent magnet correct flux and maximum performance of the magnet, thus guaranteeing the best performance of the motor itself.

Other important advantages that heat shrink tubing provides include: Unlike very expensive steel rings, heat shrink tubing wraps around and protects the ends of the magnets, which are also susceptible to corrosion, which, if broken, can cause the motor to jam. Avoiding trimming during assembly using rigid rings, the heat shrink tube adheres perfectly to the magnet, holds its shape and prevents it from cracking and scratching. If the magnets are glued in place on the rotor, depending on the amount of glue used for each magnet, there can be some issues with the balance of the rotor, which means installing some complex system to balance the rotor, increasing the scrap rate.

Circular heat shrink tubing for easy rotor balancing, reducing production scrap, balancing inspection as part of the assembly process can be eliminated, eliminating potentially costly costs, and eliminating the need for manual ties with epoxy impregnated tape It also avoids the too slow resin activation time in the oven, thereby improving productivity and reducing hidden production costs. Heat shrink tubing can also be used successfully in conjunction with the epoxy glue used to hold the magnets, ensuring additional protection against the potential failure of the glue and the detachment of the magnets, as well as from scratches or other contaminants.

in conclusion

In motors using ring magnets compression moulded from Nd-Fe-B NdFeB magnets with the addition of a thermosetting resin (plastic ferrite), the heat shrink sleeve also protects the magnets from damage due to the brittleness of the alloy used corrosion, thus preventing the motor from getting stuck. The heat-shrinkable polyester tube also guarantees thermal insulation (Class B), dielectric (4-5 kV) insulation, and is used at temperatures up to 150-155°C peak. Quickly and easily locate the thickness, size and weight of permanent magnets in automated industrial processes, facilitates perfect adhesion of heat shrinkable tubes to rotors and magnets, and achieves low cost and easy disassembly during recycling of permanent magnets.

XINDA

XINDA