![]()

eVTOL refers to an aircraft that uses electricity as a flying power source and has vertical take-off and landing capabilities . It has the characteristics of vertical take-off and landing, intelligent operation, and fast maneuverability. Compared with traditional modes of travel such as cars and high-speed trains, eVTOL has the advantages of high efficiency, convenience, low noise, low carbon emissions, comfort and privacy within a specific range; compared with traditional aircraft such as helicopters, it has cost and environmental advantages.Currently, companies planning to develop eVTOL include traditional aviation giants, automobile companies and emerging eVTOL companies.1) Aviation giants: Traditional aviation giants such as Boeing, Airbus, Bell, Embraer, and AVIC have all deployed eVTOL research and development;2) Automobile companies: Geely, Audi, Hyundai, Toyota, Xiaopeng and other automobile companies have also joined the research and development ranks;3) Emerging eVTOL companies: New technology companies such as Ehang have gradually become the main force in eVTOL research and development for urban air traffic.To learn more about low-altitude economy, you can scan the QR code to follow "Low-altitude Economy", join the industry group, and obtain valuable information and industry chain maps. Next, we will focus on analyzing the eVTOL motor part:

Scale: eVTOL brings about a tens of billions of yuan motor OEM market, and the market size is considerable due to the high replacement frequency.eVTOL has brought the domestic motor pre-installation market to tens of billions of yuan. Domestic motors are mainly used in the domestic market. According to the "Passenger eVTOL Application and Market White Paper", it is estimated that the cumulative domestic eVTOL demand in 30 years will be 16,316 aircraft. Assuming that the motor and electronic control of a single aircraft cost 800,000 yuan, the corresponding domestic eVTOL motor pre-installation market size is about 13.1 billion yuan.The service life of eVTOL is about 15-20 years, and the motor needs to be replaced 3-4 times. Compared with cars, eVTOL has extremely high requirements for reliability. It is reported that the error rate in manned scenarios is required to be controlled within 10-9. Compared with the price of traditional aircraft engines of more than tens of millions of dollars, the price of motors is relatively cheap. Therefore, in order to ensure the service life of eVTOL, the motor replacement will be more frequent than that of cars .Therefore, assuming that the service life of eVTOL is 20 years, the motor is replaced every four years, and the average replacement price of a single machine is 600,000 yuan, then the motor of an eVTOL must be replaced four times during its life cycle, and the replacement cost is 2.4 million yuan. The cumulative domestic demand for eVTOLs in 30 years is 16,316 units, corresponding to a motor aftermarket market of approximately 39.2 billion yuan.It is worth mentioning that the three-electric costs of eVTOL account for nearly half and occupy an important position .

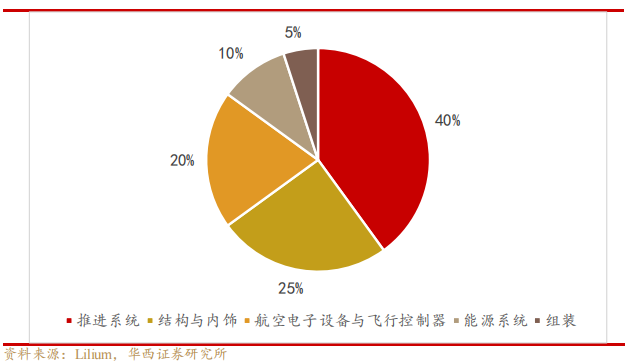

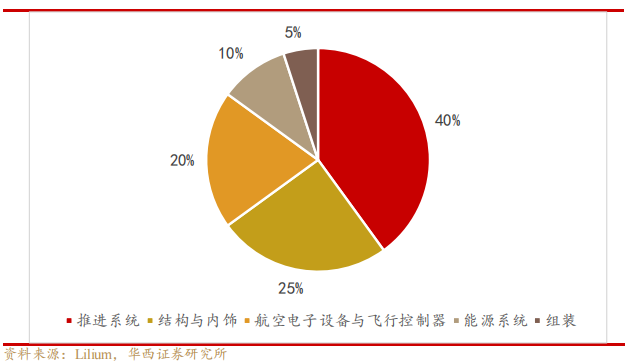

Lilium eVTOL cost breakdown

In terms of upstream components, the power system of electric aircraft is significantly different from that of traditional aircraft using fuel engines. According to the draft for comments on the series of group standards for electric aircraft electric propulsion systems disclosed on the official website of AOPA, in electric aircraft, motors, controllers and other components together constitute the electric propulsion system, and together with batteries, thrusters and other components, they constitute a complete power unit. In terms of cost structure, taking Lilium's eVTOL product as an example, the propulsion system/structure and interior/avionics equipment and flight controller/energy system/assembly account for 40%/25%/20%/10%/5% respectively, and the propulsion system and energy system cost account for 50%; specifically for the three electrics (batteries, motors, and electronic controls), according to an interview article on the Science and Technology Power WeChat account, the three electrics account for about 45% to 50% of the cost structure of electric aircraft, occupying an important position.

Barriers: The barriers to eVTOL motors are high power density and airworthinessThe motor is an important part of the eVTOL electric power system. The electric energy of the power battery or fuel cell is used to drive the ducted fan or rotor through the motor. The power density of the motor directly affects the payload capacity of the flying car. The motor's wide range of variable working conditions power output capacity, reliability and environmental adaptability are important factors that determine the power characteristics and safety of the flying car. Different motors are used in different application scenarios for different airworthiness requirements.

Torque and speed curves of automotive (top) and eVTOL (bottom) motors

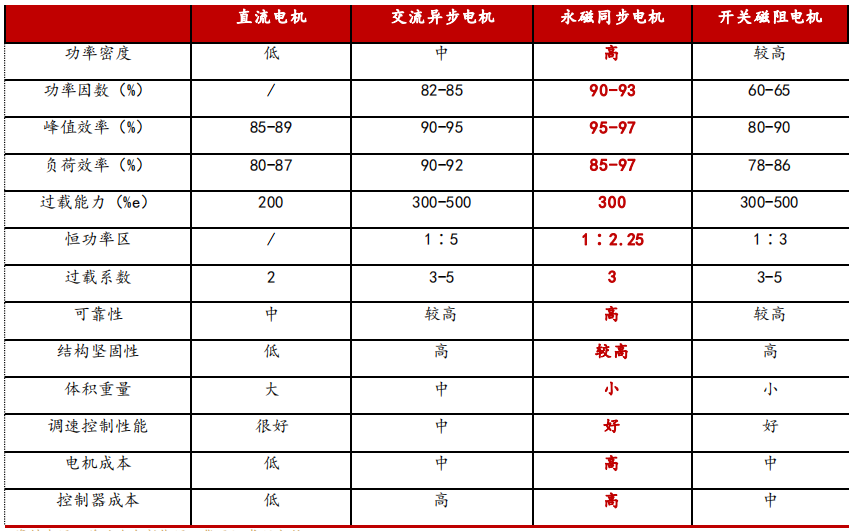

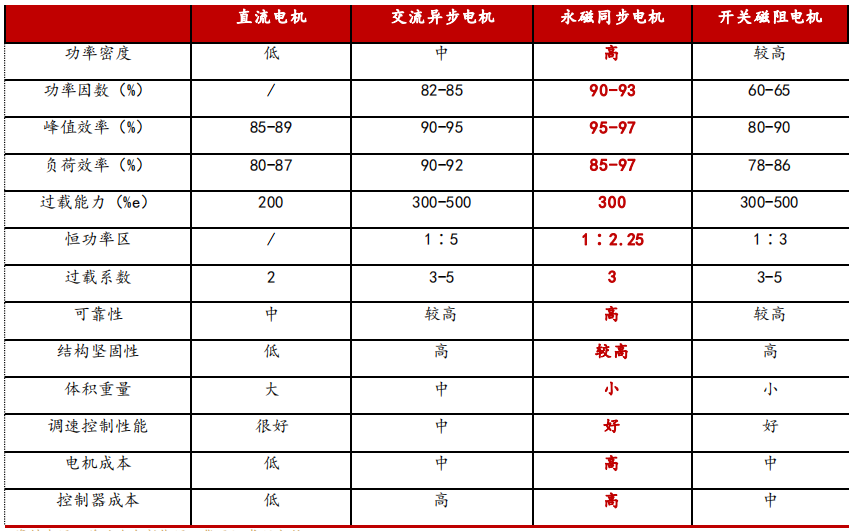

According to the working power supply, motors can be mainly divided into DC motors and AC motors.DC motors are divided into brushed DC and brushless DC. Brushed DC includes permanent magnet DC and electromagnetic DC.1) Electric vehicles : It is common to use permanent magnet synchronous motors. The higher efficiency and higher torque of permanent magnet motors can provide a better driving experience. At the same time, the high power density of permanent magnet motors can also help electric vehicles obtain higher power in the same volume.2) UAVs : Brushless DC motors are commonly used. Since there are no brushes and commutators, it has the advantages of high efficiency, low maintenance cost, and long life. Its main function is to generate rotational torque to drive the rotation of the propeller, thereby realizing the flight of the UAV. The use of brushless DC motors on UAVs is that brushless DC motors have low weight and noise, and low maintenance costs, which are suitable for the flight requirements of UAVs; secondly, brushless DC motors have high speeds, which are suitable for the high-speed flight requirements of UAVs.3) eVTOL : The requirements for motor efficiency and torque density are relatively high, and permanent magnet synchronous motors are a very promising solution for electric propulsion power systems. Compared with DC motors and induction motors, permanent magnet synchronous motors have advantages such as high power density, wide speed regulation range, and large electromagnetic torque. In addition, their ability to maintain full torque is very suitable for the power requirements of eVTOL during takeoff and landing, and is a very promising solution for electric propulsion power systems.Current electric vertical take-off and landing aircraft, such as JobyS4 and ArcherMidnight, all use permanent magnet synchronous motors.

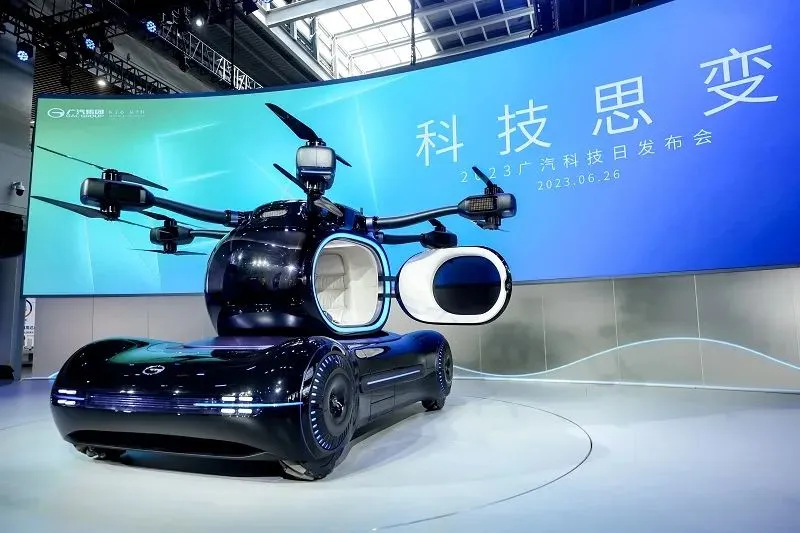

Comparison of different motor characteristicsAviation-grade motors have high requirements for safety, environmental adaptability, and power density.1) In terms of safety, considering the aviation application scenario, the primary consideration is that the aircraft can have 50% redundant power output in an emergency and be equipped with an emergency derating design;2) In terms of environmental adaptability, aviation-grade motors have high requirements for high and low temperatures, humidity and heat, low temperature and low pressure, salt spray, ozone, electromagnetic compatibility, vibration, etc., and need to adapt to various extreme environments ;3) In terms of quantity, electric vehicles are usually equipped with 1-2 motors, while eVTOL currently requires at least 8 motors to drive . Since flying cars have high requirements for safety and reliability, in any case, even if at most one motor fails, the flying car can still maintain stable suspension;4) Aviation pays more attention to power density. According to the "Research, Development and Key Technologies of Flying Cars", the rated dry mass power density of automotive motors is about 2kW/kg at most. Aviation propulsion motors can make the rated power density of the motor body exceed 5kW/kg by using insulating materials with higher temperature resistance limits, permanent magnet materials with higher magnetic energy density and lighter structural materials .By improving the electromagnetic structure design of the motor, such as adopting Halbach magnetic array, coreless structure, Litz wire winding and other technologies, as well as improving the heat dissipation design of the motor, it is expected that the rated power density of the motor body will reach 10kW/kg in 2030 and exceed 13kW/kg in 2035 .The main development trend of eVTOL power systems is to reduce the weight of motor structures and the auxiliary weight of cooling systems by improving electromagnetic design technology, thermal management technology and lightweight technology, and continuously improve the power density of motors and their power output capabilities over a wide range of variable operating conditions.GAC Group GOVE flying carAt present, most motors are shipped with the main engine manufacturers in a random manner to build high customer stickiness .

Currently, most motor products are supplied to OEMs and are airworthy. Since the OEMs' airworthiness requirements are high and complex, it is expected that motor manufacturers and OEMs will form a stable cooperation and supply relationship after passing the airworthiness test. Switching suppliers will bring greater risks to product reliability.

In addition, the Chinese authorities can use the motor as equipment, which makes it difficult to conduct airworthiness tests alone. The airworthiness regulations apply to the China Civil Aviation Technical Standards Order (CTSO), which is issued in accordance with the China Civil Aviation Regulations "Civil Aviation Materials, Parts and Airborne Equipment Technical Standards Order" (CCAR37), which is a set of guidelines that must be followed when certain aviation materials, parts and airborne equipment used on civil aircraft undergo airworthiness review.The FDR (Flight Data Recorder) to be marked shall meet the requirements of the European Civil Aviation Equipment Organization EUROCAE standard ED-112A "Minimum Performance Requirements for Crash-Resistant Airborne Recording Systems". For environmental identification, the test conditions specified in ED-112A shall be followed, and the standard environmental conditions and test procedures applicable to the equipment shall be used to prove that the equipment performance meets the requirements.ED-112A requires the use of ED-14G or RTCA/DO-160G. For software qualification, the regulations state that if the equipment contains software, the software should be developed in accordance with the requirements of RTCA/DO-178B "Software Considerations in Airborne Systems and Equipment Qualification". For hardware design, if the hardware unit contains electronic equipment whose functions cannot be evaluated through testing and/or analysis, it should be developed in accordance with RTCA/DO-254 "Design Assurance Guide for Airborne Electronic Hardware" based on the design assurance level determined by the manufacturer of the hardware unit.1) DO-160 focuses on the physical characteristics and environmental adaptability of equipment, such as temperature, humidity, vibration, shock, etc.2) DO-178 focuses on the certification of aerospace software development. It is mainly used for the development, verification and certification of aerospace software, including flight control systems, display systems, communication systems, etc.3) DO-254 focuses on the design and verification of aerospace electronic hardware, including chips, circuit boards, sensors, etc. It is difficult for motor products to pass DO-160 certification for airworthiness alone. As a device, the motor needs to pass the DO160 environmental practicality test and must meet environmental tests such as high temperature and humidity, strong magnetism, vibration, and electromagnetic interference.Xiaopeng Flying Car "Land Aircraft Carrier"It is difficult for domestic enterprises to pass the certification. It is difficult for electronic control products to pass the DO-178 certification.If you want to manufacture qualified aircraft, the electronic control system needs to pass the DO-178 standard certification , but only two or three AVIC companies in China can pass the DO-178 certification. The DO-178 standard not only evaluates software, but also has high requirements for hardware. Currently, a large number of chips used in automobiles cannot meet the relevant requirements.Another option is for companies to design FPGA systems themselves, but they need to pass the DO-254 standard certification, which is more difficult than the DO178 standard certification. Domestic companies that can pass the DO-254 certification are also scarce.Judging from the competition landscape of the global eVTOL motor market, the early OEMs that entered the eVTOL field, such as Joby, Archer, Ehang Intelligent, and Fengfei, are all conducting independent research and development of electric propulsion systems, and designing motors in a targeted manner according to the characteristics of the company's models to meet the needs of lightweight and increased power density. Lilium has reached a cooperation with Japan's Denso Corporation and the United States' Honeywell Aerospace Corporation. The two companies jointly integrated electronic motors into Lilium's aircraft engines.Volocopter, Volante and Shi Technology all use high-performance, high-power density motors provided by Safran. Safran Group is a leading company in the field of aircraft engines and helicopter engines in the world. The company covers 13 countries around the world and can provide local services to customers in the first time.The main domestic eVTOL motor and electronic control suppliers include Wolong Electric Drive, Tianjin Santroll, and Maiji Yiwei, and companies such as Blue Ocean Huateng are interested in entering the market. Among them:1) Wolong Electric Drive : It is at the world-class level in the field of aviation electric drive and control. Since 2019, the company has been committed to the development of aviation electric drive power system products, and has gradually formed a "3+1" product layout, namely drive products with three power levels of small, medium and large and an airworthiness standard. Small power refers to 2kW~30kW products, which are mainly used in industrial drones and 1~2 eVTOLs. It has begun to supply small batches of samples to mainstream domestic logistics drone companies; medium-power products are mainly 50kW~175kW, and 4-seat manned eVTOLs are the main applications. There are technical communications with mainstream domestic eVTOL manufacturers, and related R&D projects are underway; high power is 200kW to 1MW or more, which is used in regional aircraft with more than a dozen to dozens of seats, mainly in pre-research. The company's current cooperative customers include COMAC, Shanhe Intelligent, etc.

Wolong Electric Drive was selected into the "2023 China's Top 20 Low-Altitude Economy Leading Enterprises"

2) Tianjin Songzheng : Leading in the aviation motor and electronic control industry. In the field of manned electric aviation, the company focuses on the development of electric propulsion systems with high power-to-weight ratios, and launches customized aviation motor and controller development services for flight mission power requirements. It has in-depth research and product applications in pure electric multi-rotor vertical take-off and landing, ducted fans and other aircraft with different configurations; at the same time, it has the development and manufacturing capabilities for hybrid drive airborne high-power extended-range motors and drivers.3) Jiangsu Maiji Yiwei : A core supplier of military high-power density hub motor systems. The company has already put multiple models of products into use in the military. After many iterations, the company's motor products have a maximum output power of 250kW, an efficiency of more than 95%, and two types of motors with air cooling and liquid cooling. It has gradually expanded from traditional diesel generators to permanent magnet electric generators for aviation. At present, the company has launched motor system supporting products for eVTOL.4) Blue Ocean Huateng : From automotive electronic control to eVTOL electronic control. The core team has more than ten years of technical research and development accumulation in the field of electronic control, and has a technical foundation in electric aircraft. Starting from the electronic control of new energy vehicles to develop eVTOL electronic control has obvious advantages, but eVTOL has higher requirements for safety, reliability, and lightweight. The company will appropriately tilt its R&D resources to the field of eVTOL electronic control, and strive to make breakthroughs in the design, algorithm, and lightweight research and development of eVTOL electronic control, in order to bring the product to market as soon as possible.

XINDA

XINDA