HOW TO CHOOSE A HIGH-QUALITY AUTOMOTIVE MOTOR SUPPLIER?

With the development of motor technology and miniaturization, integrated micro motors with DC motors or brushless motors combined with gearboxes are widely used in various system components of automobiles or new energy vehicles, and automobiles are becoming more and more comfortable and intelligent. Therefore, the performance of the motor directly affects the comfort of the car. Therefore, many first-tier automotive suppliers (such as car seats, tailgates, and AMT) will choose high-quality automotive motor suppliers. Here’s how to choose a high-quality automotive motor manufacturer:

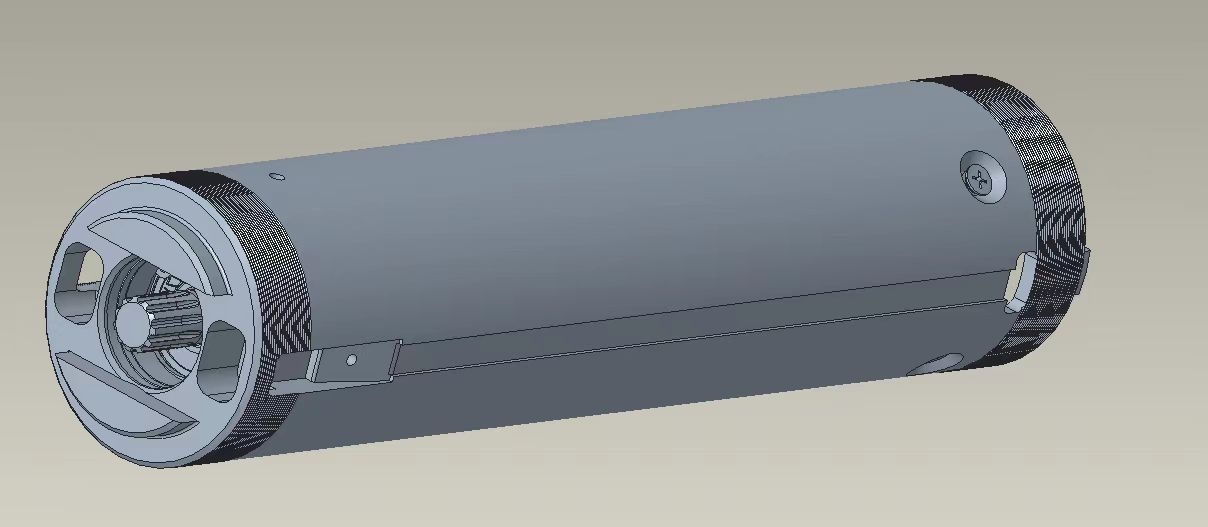

First, independent and powerful motor development capabilities.

With the development of automobile intelligence, such as the development of car seats from manual to electric, it is not only required to adjust the front and rear, up and down, angle and other positions of the seat, but also requires a memory function for these positions. This requires car seat motor manufacturers to have independent and strong development capabilities and be able to quickly develop multi-directionally adjustable car electric seat motors with position memory functions. However, the car seat motor series independently developed by Xinda Motor with independent intellectual property rights can realize 12-way adjustment such as front and rear horizontal adjustment, up and down adjustment, forward tilt adjustment, backward tilt adjustment, and backrest angle adjustment. It also comes with its own The Moore memory function fully meets the development needs of electrified car seats. After the car seat motor series developed by Xinda is developed, in addition to testing life, noise, operating accuracy, etc., it also needs to pass three major tests:

First, a long-term torque test ensures that the motor outputs sufficient torque, and the output torque is stable and meets the most important performance requirements.

Second, high-frequency EMC testing ensures that the motor's ability to resist electromagnetic interference meets customer requirements.

Finally, high and low temperature tests are conducted to ensure that Xinda's seat motors can operate normally and are stable and reliable when the car is in the range of -40°C to +90°C.

Second, strong production strength and advanced processing technology.

Car companies have strict requirements on motor performance. Only with such strict requirements can they produce high-quality cars. Therefore, this requires motor companies not only to have independent and strong R&D capabilities, but also to have strong production capabilities and advanced processing technology, so that they can produce high-performance and high-quality automotive motors that meet the requirements of car companies; and large quantities are required Production, strict quality control, and fast delivery require motor companies to have advanced production lines. However, Xinda Motor has a production base of 72,000 square meters, 42 advanced production lines, and can produce 100,000 high-quality motors per day. It is a car seat manufacturer, tailgate manufacturer, transmission manufacturer, sunroof manufacturer, car window manufacturer, large A high-quality strategic partner for first-tier automotive parts suppliers such as lamp manufacturers, steering wheel manufacturers, and door manufacturers. For more details, please click "Automotive Motor Solution".

The above are the two conditions that a high-quality automotive motor manufacturer should meet.

XINDA

XINDA