HOW TO SELECT INDUSTRIAL AUTOMATION MOTORS?

Understanding the major types of loads, motors, and applications can help simplify the selection of industrial motors and accessories. There are many aspects to consider when selecting an industrial motor, such as application, operation, mechanical and environmental issues. Generally speaking, you can choose between AC motors, DC motors, or servo/stepper motors. Knowing which one to use depends on the industrial application and whether there are any special needs. Industrial motors require a constant or variable torque and horsepower depending on the type of load the motor drives. The size of the load, required speed and acceleration/deceleration - especially if the speed is fast and/or frequent - will determine the torque and horsepower required. The requirements for controlling motor speed and position also need to be considered.

There are four types of industrial automation motor loads:

1, Adjustable horsepower and constant torque:Variable horsepower and constant torque applications include Conveyors, cranes and gear pumps. In these applications, the torque is constant because the load does not change. The required horsepower may vary depending on the application, which makes constant speed AC and DC motors a good choice.

2, Variable torque and constant horsepower: An example of variable torque and constant horsepower application is the machine rewinding paper. The velocity of the material remains the same, which means the horsepower doesn't change. However, as the roll diameter increases, the load changes. In small systems this is a good application for DC motors or servo motors. Regenerative power is also a concern and should be considered when sizing industrial motors or selecting energy control methods. AC motors with encoders, closed-loop controls, and full-quadrant drives may be beneficial for larger systems.

3,Adjustable Horsepower and Torque: Fans, centrifugal pumps and agitators require variable horsepower and torque. As industrial motor speed increases, load output also increases with the required horsepower and torque. These types of loads are where the motor efficiency discussion begins, with inverter loaded AC motors using variable speed drives (VSDs).

4, Position control or torque control: Applications such as linear drives that require precise movement to multiple positions require tight Position or torque control often requires feedback to verify correct motor position. Servo motors or stepper motors are the best choices for these applications, but DC motors with feedback or inverter-loaded AC motors with encoders are often used in steel or paper production lines and similar applications.

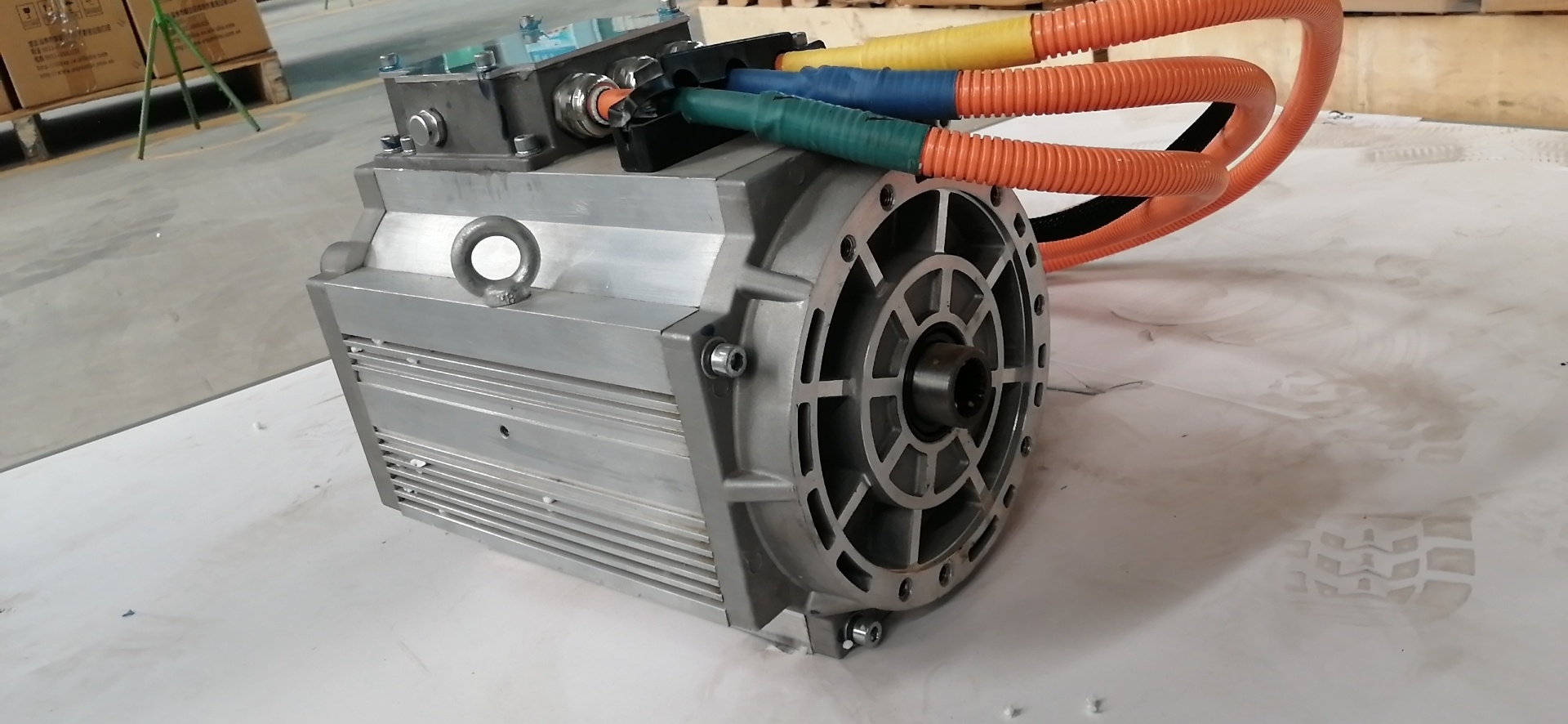

Different industrial motor types

Although there are more than 36 types of AC/DC motors used in industrial applications. While there are many types of motors, there is substantial overlap in industrial applications, and the market has pushed to simplify motor selection. This narrows down the practical selection of motors in most applications. The six most common motor types, suitable for the vast majority of applications, are brushless and brushed DC motors, AC squirrel cage and wound rotor motors, and servo and stepper motors. These motor types are suitable for the vast majority of applications, while other types are only used in special applications.

Three Main Types of Industrial Motor Applications

The three main applications of industrial motors are constant speed, variable speed, and position (or torque) control. Different industrial automation situations require different applications and problems and their own problem sets. For example, if the top speed is less than the base speed of the motor, a gearbox is required. This also allows a smaller motor to run at a more efficient speed. While there is a wealth of information online about how to size a motor, users must consider many factors as there are many details to consider. Calculating load inertia, torque and speed requires the user to know parameters such as the total mass and size (radius) of the load, as well as friction, gearbox losses, and machine cycles. Changes in load, speed of acceleration or deceleration, and the duty cycle of the application must also be considered, otherwise industrial motors may overheat. AC induction motors are a popular choice for industrial rotary motion applications. After motor type selection and sizing, users also need to consider environmental factors and motor housing types, such as open frames and stainless steel housings for washing applications.

Three main issues in industrial motor selection

1. Constant speed application?

In constant speed applications, motors often run at approximate speeds with little or no consideration for acceleration and deceleration ramps. This type of application typically runs using full row on/off control. The control circuit usually consists of a branch circuit fuse with a contactor, an overload industrial motor starter, and a manual motor controller or soft starter. Both AC and DC motors are suitable for constant speed applications. DC motors provide full torque at zero speed and have a large installed base. AC motors are also a good choice because they have a high power factor and require little maintenance. In comparison, the high-performance characteristics of a servo or stepper motor would be considered overkill for a simple application.

2. Variable speed app?

Variable speed applications often require tight speed and velocity changes, as well as defined acceleration and deceleration ramps. In practical applications, reducing the speed of industrial motors, such as fans and centrifugal pumps, usually improves efficiency by matching power consumption to the load, rather than running at full speed and throttling or suppressing output. These are very important to consider in conveying applications such as bottling lines. The combination of AC motors and VFDs is widely used to increase efficiency and works well in various variable speed applications. Both AC and DC motors with appropriate drives work well in variable speed applications. DC motors and drive configurations have long been the only option for variable speed motors and their components have been developed and proven. Even now, DC motors are popular in variable speed, fractional horsepower applications and are useful in low speed applications as they can provide full torque at low speeds and constant torque at a wide range of industrial motor speeds. Maintenance of DC motors is an issue to consider, however, as many require brushes for commutation and wear due to contact with moving parts. Brushless DC motors eliminate this problem, but they are more expensive upfront and the range of industrial motors available is smaller. Brush wear is not an issue with AC induction motors, and Variable Frequency Drives (VFD) provide a useful option for increased efficiency for applications exceeding 1 horsepower, such as fans and pumping. Choosing the type of drive to run an industrial motor can add some position awareness. If the application requires it, an encoder can be added to the motor and the drive can be specified to use encoder feedback. Therefore, this setup can provide servo-like speeds.

3. Is position control required?

Tight position control is achieved by continuously verifying the motor's position as it moves. Applications such as positioning linear drives can use stepper motors with or without feedback or servo motors with inherent feedback. A stepper moves precisely to a position at moderate speed and then holds that position. Open loop stepper systems provide powerful position control if appropriately sized. When there is no feedback, the stepper will move the exact number of steps unless it encounters a load interruption that exceeds its capabilities. As the speed and dynamics of the application increase, open-loop stepper control may not meet the system's requirements, requiring an upgrade to a stepper or servo motor system with feedback. A closed-loop system provides precise, high-speed motion profiles and precise position control. Servos provide higher torque at high speeds than steppers and also work better with high dynamic loads or complex motion applications. For high-performance motion with low position overshoot, the reflected load inertia should match the servo motor inertia as closely as possible. In some applications, a mismatch of up to 10:1 is sufficient, but a 1:1 match is optimal. Gear reduction is a good way to solve the inertia mismatch problem because the inertia of the reflected load decreases as the square of the transmission ratio, but the inertia of the gearbox must be taken into account in the calculation.

XINDA

XINDA