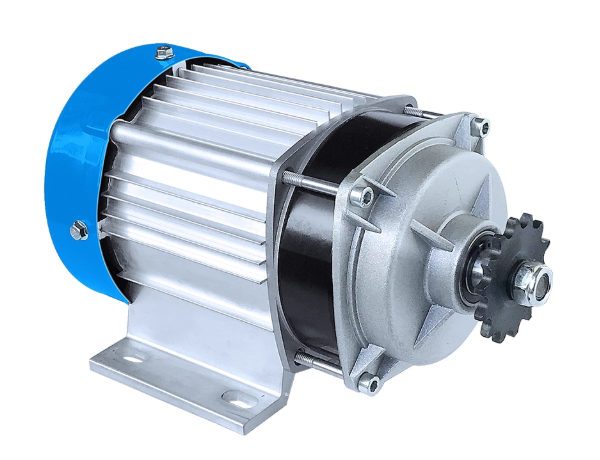

AC asynchronous motor 30KW144V for electric vehicles with low speed

Rated voltage: 144V

Rated current: 258A

Rated power: 30KW

Rated torque: 95.5N.m

Rated speed: 3000rpm

Insulation class: H grade

Protection rating: IP66

Working time: S2-60min

Technology Requirement

All parts should be kept clean and intact before assembly; when installing and tightening the threads of the motor, add thread locking and sealant, and tighten the torque according to the standard. Tighten crosswise, symmetrically, gradually and evenly, and the threads must be marked after tightening; during the assembly process, the air gap between the stator and rotor should be ensured to be uniform, free of friction and abnormal noise, and no foreign matter should enter the inside of the motor; after assembly, the overall appearance of the product is clean and free of dirt , there are no obvious defects, all labels are firmly in the correct position; turn it gently by hand, the motor should be light and free of jamming. Facing the motor output shaft, when the letter sequence of the motor wire ends is the same as the power phase sequence, the motor rotation direction is clockwise.

Coat the outer surface of the motor shaft extension with anti-rust oil for anti-rust treatment

When installing the oil seal, check whether the lip is damaged or deformed, whether the spring is falling off or rusty, and apply an appropriate amount of lubricating oil between the oil seal lips and the outer circumferential surface of the shaft extension; when installing, it must be installed flat and not tilted. For specific operations, refer to the "Skeleton Oil Seal Installation Process Code". The dimensional tolerances not noted shall be based on GB/T1804-m level, and the geometric tolerance shall be based on GB/T1184-k level; 6. The speed sensor lead length is 500+30mm, and the temperature sensor lead length is 500+30mm. Temperature sensor model: KTY84-150, 20 Resistance value at ℃: 5442-6182. The winding of the drive motor should be able to withstand the power frequency withstand voltage test of 1500VAC for the temperature sensor, the test time is 1 minute, and the leakage current without breakdown should not be greater than 5mA.

The water inlet and outlet of the motor are covered with rubber caps (manufacturer: Senrui Rubber, rubber cap number: 057831) to prevent dust when leaving the factory.

Safety testing:

Definition of insulation resistance and withstand voltage of phase line pair chassis: cold insulation resistance is not less than 20M2 (DC1000V); withstand voltage is 1500VAC, 50Hz, 1min, and leakage current is not more than 10mA. Stator coil inter-turn insulation impact withstand voltage test, the test voltage peak value is 1800VDC, the wave front is 0.5uS, and there should be no breakdown or flicker for 1-3 seconds.

During debugging, it should operate flexibly, without jamming or abnormal noise. During transportation, care should be taken to prevent collision and deformation.

There is no gap in the crimping of the speed sensor and temperature sensor connector pins, and there is no looseness in the wire compression part. The terminal pull-off force complies with QC/T29106-2016 "Technical Conditions for Automotive Low-Voltage Wire Harnesses" 4.4.6. The pull force Test>110N:12. The motor must meet the following standards:

GB/T18488.1-2015 "Motors and Controllers for Electric Vehicles Part 1: Technical Conditions" "Motors and Controllers for Electric Vehicles Part 2: Test Methods"; GB/T 18488.2-2015GB/T29307-2012 "Experimental Method for Reliability of Drive Motor Systems for Electric Vehicles"; environmental protection requirements comply with GB/T 30512-2014 "Requirements for Prohibited Substances in Automobiles".

Home

Home  EV KITS

EV KITS

Electric Tricycle kits

Electric Tricycle kits Four-wheelers kits

Four-wheelers kits EV Motor

EV Motor

Oil Pump Motor

Oil Pump Motor EV Driving Motor

EV Driving Motor EV and auto parts

EV and auto parts Conversion Kits

Conversion Kits XD Motor

XD Motor

XD DC Motor

XD DC Motor XD AC Motor

XD AC Motor Industrial Motors

Industrial Motors Motor Drive Machines

Motor Drive Machines Knowhow

Knowhow  About XD

About XD

Company Profile

Company Profile Honor

Honor Factory Appearance

Factory Appearance XINDA Team

XINDA Team Events

Events

Summit

Summit Clients Visit

Clients Visit Exhibition

Exhibition Contact

Contact

XINDA

XINDA