![]() [Introduction] High Efficiency Motor refers to a motor with higher efficiency, and its efficiency value can reach the second level of GB18613-2012 standard. High-efficiency motors use new motor designs, new processes and new materials to improve output efficiency by reducing the loss of electromagnetic energy, thermal energy and mechanical energy. Compared with standard motors, its efficiency is improved by an average of 4%.

[Introduction] High Efficiency Motor refers to a motor with higher efficiency, and its efficiency value can reach the second level of GB18613-2012 standard. High-efficiency motors use new motor designs, new processes and new materials to improve output efficiency by reducing the loss of electromagnetic energy, thermal energy and mechanical energy. Compared with standard motors, its efficiency is improved by an average of 4%.

In May 2020, China announced the latest motor energy efficiency standard "GB18613-2020 Motor Energy Efficiency Limitations and Energy Efficiency Levels" . This standard will be officially implemented on June 1, 2021. Energy efficiency motors below IE3 (international standard) will be forced to cease production . Domestic motors The industry has fully entered the era of IE3 high efficiency.

The new national standard also stipulates that from the date of implementation of the standard, IE3 efficiency will become the lowest energy efficiency limit value (three-level energy efficiency) of three-phase asynchronous motors in China. Three-phase asynchronous motors (such as YE2 series motors, etc.) that are lower than the IE3 energy efficiency limit value Reproduction and sales are not allowed, indicating that the efficiency level of China's small and medium-sized three-phase asynchronous motors has once again increased by a level. The new national standard also lists IE4 efficiency as a secondary energy-saving evaluation value indicator.

The differences in motor energy efficiency labels after the implementation of the new GB 18613-2020 national standard are as follows:

|

|

|

|

|

|

Level 1 energy efficiency

|

|

|

Level 2 energy efficiency

|

|

|

Level 3 energy efficiency

|

|

|

|

|

|

|

|

Level 1 energy efficiency

|

|

|

Level 2 energy efficiency

|

|

|

Level 3 energy efficiency

|

|

Regarding the new version of the motor energy efficiency standard GB18613-2020, Mr. Chen Weihua, special advisor to the president of Shanghai Electrical Equipment Research Institute (Group) Co., Ltd., believes that the motors used for fans and water pumps are within the scope of the GB18613 standard, but the efficiency of the fans and water pump units does not fall within the scope of the standard. Specially designed motors such as brake motors and frequency conversion motors are also not within the scope of application of this standard.

As far as motor companies are concerned, starting from June 1, 2021, motors that do not meet the IE3 energy efficiency limit value are not allowed to be produced and sold, and users are not allowed to purchase them. Therefore, motor companies must start from technology, equipment, processes, materials and sales. In all aspects, we are fully prepared to produce and sell energy-efficiency motors of IE3 and above.

Compared with IE2, the cost of IE3 increases by about 20%; compared with IE3, the cost of IE4 also increases significantly. Therefore, motor companies must tap the potential in design, process and other aspects to reduce costs on the premise that their products meet the required energy efficiency indicators. At present, many motor companies have begun to implement intelligent manufacturing so that motor products can achieve a higher level of consistency. In addition, existing motor products can be better improved in terms of technology (such as processing accuracy) and equipment.

At present, my country's industrial energy consumption accounts for about 70% of the total energy consumption, of which motor energy consumption accounts for about 60% to 70% of the industrial energy consumption. Adding non-industrial motor energy consumption, the actual energy consumption of the motor accounts for about 50% of the total energy consumption. above. However, the application proportion of high-efficiency and energy-saving motors is currently low. According to a sample survey of 198 motors from key domestic enterprises by the National Small and Medium-sized Motor Quality Supervision and Inspection Center, only 8% of them are high-efficiency and energy-saving motors that have reached level 2 or above, which has caused a huge waste of resources for the entire society.

Energy-saving measures for high-efficiency motors

Measures to improve the efficiency of electric motors. Energy saving of motors is a systematic project that involves the entire life cycle of the motor, from motor design and manufacturing to motor selection, operation, adjustment, maintenance, and scrapping. The effect of energy-saving measures must be considered from the entire life cycle of the motor. In this regard, domestic and foreign efforts mainly consider improving the efficiency of the motor from the following aspects.

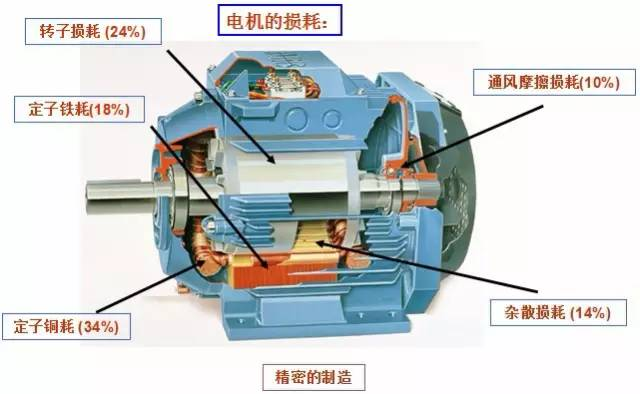

The design of energy-saving motors refers to the use of modern design methods such as optimized design technology, new material technology, control technology, integration technology, and test and detection technology to reduce the power loss of the motor, improve the efficiency of the motor, and design an efficient motor. While the motor converts electrical energy into mechanical energy, it also loses a part of its energy. Typical AC motor losses can generally be divided into three parts: fixed loss, variable loss and stray loss. Variable losses change with load and include stator resistance losses (copper losses), rotor resistance losses and brush resistance losses; fixed losses have nothing to do with load and include iron core losses and mechanical losses. Iron loss is composed of hysteresis loss and eddy current loss, which is proportional to the square of the voltage, and hysteresis loss is also inversely proportional to frequency; other stray losses are mechanical losses and other losses, including friction losses of bearings and fans and rotors. etc. Windage losses due to rotation.

two

Characteristics of high-efficiency motors

1. Save energy and reduce long-term operating costs. It is very suitable for use in textiles, fans, water pumps, and compressors. The purchase cost of the motor can be recovered by saving electricity in one year;

2. It can be started directly or adjusted with a frequency converter, and the asynchronous motor can be fully replaced;3. The rare earth permanent magnet high-efficiency energy-saving motor itself can save more than 15℅ of electric energy than ordinary motors;4. The power factor of the motor is close to 1, which improves the quality factor of the power grid without adding a power factor compensator;5. The motor current is small, saving power transmission and distribution capacity and extending the overall operating life of the system;6. Energy-saving budget: Taking a 55-kilowatt motor as an example, a high-efficiency motor saves 15℅ more electricity than an ordinary motor. The electricity cost is calculated at 0.5 yuan per kilowatt hour. The cost of replacing the motor can be recouped within one year by saving electricity.Advantages of high-efficiency motorsDirect start, full replacement of asynchronous motor.The rare earth permanent magnet high-efficiency energy-saving motor itself can save more than 3℅ of electric energy than ordinary motors.The power factor of the motor is generally higher than 0.90, which improves the quality factor of the power grid without adding a power factor compensator.The motor current is small, saving power transmission and distribution capacity and extending the overall operating life of the system.Adding a driver can realize soft start, soft stop and stepless speed regulation, further improving the power saving effect.

three

Five major losses of motors

The main means to reduce the I^2R loss of the motor stator. The most commonly used methods in practice are:1. Increase the stator slot cross-sectional area. Under the same stator outer diameter, increasing the stator slot cross-sectional area will reduce the magnetic circuit area and increase the magnetic density of the teeth;2. Increase the stator slot full rate, which is more effective for low-voltage small motors. Applying optimal winding and insulation dimensions and large conductor cross-sectional area can increase the stator slot full rate;3. Minimize the length of the stator winding end. The stator winding end loss accounts for 1/4 to 1/2 of the total winding loss. Reducing the winding end length can improve the motor efficiency. Experiments show that the end length is reduced by 20% and the loss is reduced by 10%.The I^2R loss of the motor rotor is mainly related to the rotor current and rotor resistance. The corresponding energy-saving methods mainly include:1. Reduce the rotor current, which can be considered from two aspects: increasing the voltage and motor power factors;2. Increase the rotor slot cross-sectional area;3. Reduce the resistance of the rotor winding, such as using thick wires and low-resistance materials. This is more meaningful for small motors, because small motors generally have cast aluminum rotors. If a cast copper rotor is used, the total loss of the motor can be reduced by 10%. ~15%, but today's cast copper rotors require high manufacturing temperatures and the technology has not yet been popularized, so their costs are 15% to 20% higher than those of cast aluminum rotors.Motor iron loss can be reduced by the following measures:1. Reduce the magnetic density and increase the length of the iron core to reduce the magnetic flux density, but the amount of iron used in the motor will increase;2. Reduce the thickness of the iron chips to reduce the loss of induced current. For example, using cold-rolled silicon steel sheets instead of hot-rolled silicon steel sheets can reduce the thickness of the silicon steel sheets, but thin iron chips will increase the number of iron chips and the cost of motor manufacturing;3. Use cold-rolled silicon steel sheets with good magnetic permeability to reduce hysteresis loss;4. Use high-performance iron chip insulation coating;5. Heat treatment and manufacturing technology. The residual stress after processing the iron sheet will seriously affect the loss of the motor. When processing silicon steel sheets, the cutting direction and punching shear stress have a greater impact on the loss of the iron core. Cutting along the rolling direction of the silicon steel sheets and heat-treating the silicon steel punched sheets can reduce the loss by 10% to 20%.Today’s understanding of motor stray losses is still in the research stage. Some of the main methods to reduce stray losses today are:1. Use heat treatment and finishing to reduce short circuit on the rotor surface;2. Insulation treatment on the inner surface of the rotor slot;3. Reduce harmonics by improving the stator winding design;4. Improve the rotor slot design and cooperation to reduce harmonics, increase stator and rotor tooth slots, design the rotor slot shape into inclined slots, and use series-connected sinusoidal windings, scattered windings and short-distance windings to greatly reduce high-order harmonics; Using magnetic slot mud or magnetic slot wedges to replace the traditional insulating slot wedges and filling the slots of the motor stator core with magnetic slot mud is an effective method to reduce additional stray losses.To people's due attention, it accounts for about 25% of the total loss of the motor. Friction losses are mainly caused by bearings and seals, which can be reduced by the following measures:1. Reduce the size of the shaft as much as possible, but it must meet the requirements of output torque and rotor dynamics;2. Use high-efficiency bearings;3. Use efficient lubrication systems and lubricants; As industrial power, motor products are highly dependent on the country's development speed and industrial policies. Therefore, how to seize market opportunities, adjust product structure in a timely manner, develop marketable products, choose differentiated energy-saving motor products, and keep up with the national industry Policy is the key. From a global perspective, the motor industry is developing towards high efficiency and energy saving, with huge development potential. Developed countries have successively formulated energy efficiency standards for motors. Developed countries such as Europe and the United States continue to improve motor energy efficiency access standards, and basically all use high-efficiency energy-saving motors. Some areas have begun to use ultra-efficient energy-saving motors.A certain company used to use Y series ordinary 7.5KW motors. A total of 10 units were operated simultaneously in the factory, running 8 hours a day and 300 days a year. This year, the company upgraded its equipment and replaced it with 10 motors of model YX3-132M-4P-7.5KW. The power is still the same, but it saves a lot of power.With the same power of 7.5KW, the efficiency of the ordinary Y motor is 87%, and the efficiency of the high-efficiency energy-saving motor is 90.1%, then throughout the year:◆ The electricity consumption of Y-132M-4P-7.5KW running for one year is: (7.5/0.87)*8*300=20,689.6 kWh◆ The electricity consumption of YX3-132M-4P-7.5KW after running for one year is:(7.5/0.901)*8*300=19,977.8 degrees◆ Using a high-efficiency energy-saving motor will save electricity throughout the year: 20689.6-19977.8=711.8 degreesThis company uses 10 7.5KW high-efficiency and energy-saving motors, which can save 7118 degrees of electricity a year !

XINDA

XINDA