What is pump-electric motor Alignment? How to find out?

Therefore, the alignment of the pump and motor coupling is one of the most important work links in the installation and maintenance process.

When installing a new pump, it is not necessary to check the verticality between the end face of the coupling and the axis, but when installing an old pump, it must be carefully checked, and if it is not vertical, it must be adjusted to be vertical before alignment. Generally, the following four situations may be encountered.

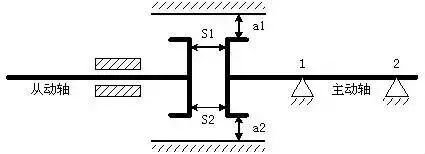

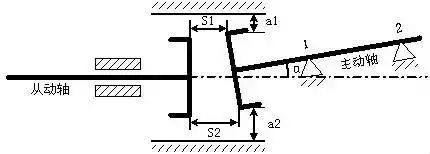

1), S1=S2, a1=a2 The end faces of the two halves of the backrest wheel are in the correct position that is both parallel and concentric, and at this time the two axes must be on a straight line.

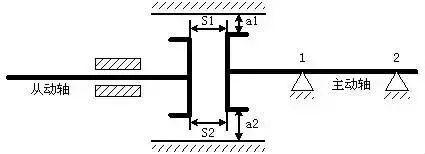

2) S1=S2, a1≠a2 The end surfaces of the two halves of the backrest wheels are parallel but the axes are not concentric. At this time, there is a parallel radial displacement e=(a2-a1)/2 between the two axes.

3) S1≠S2, a1=a2 Although the end faces of the two halves of the backrest wheel are concentric but not parallel, there is an angular displacement α between the two axes.

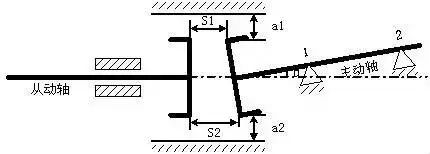

4) S1≠S2, a1≠a2 The end faces of the two halves of backrest wheels are neither concentric nor parallel, and there is both radial displacement e and angular displacement α between the two axes.

The first situation of the coupling is the ideal state that we need to strive to achieve in the alignment, while the other three states are not correct, and we need to make adjustments to make it reach the first situation.

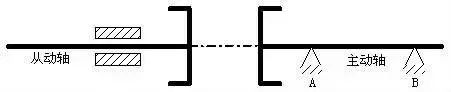

When installing the equipment, first install the driven machine (that is, the pump head that is often called) so that its axis is in a horizontal position, and then install the main machine (that is, the motor that is often called), so you only need to adjust the motor when aligning, that is, Add adjustment shims under the feet of the motor to adjust.

The following mainly introduces the two commonly used measurement and adjustment methods in the maintenance process, which can be divided into different types according to different measurement tools:

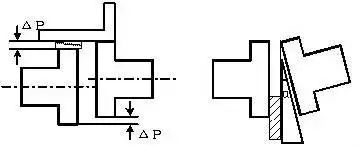

1) Use a knife-shaped ruler and a feeler gauge to measure the non-concentricity of the coupling and use a wedge-shaped gap rail or a feeler gauge to measure the non-parallelism of the coupling end face. This method is suitable for low-speed elastic connections and low precision requirements. device of.

2) Measure the non-concentricity and non-parallel conditions of the two couplings by using the dial indicator and the table frame or special alignment tools (such as laser alignment correction instrument). This method is suitable for high speed, rigid connection and precision requirements High rotating equipment.

Notice:

1) When aligning with a feeler gauge and a knife-shaped ruler, the surface of the radial end face of the coupling should be flat, smooth, rust-free, and burr-free.

2) In order to see the light of the knife-shaped ruler clearly, it is best to use a flashlight.

3) For the final measured value, the anchor bolts of the motor should be fully tightened without loosening.

4) When aligning with a special tool, make the same mark. In order to avoid increasing the error of the measurement data, the backrest wheel should be divided into 4-8 points in order to obtain accurate data.

5) Keeping good records is an important part of correcting.

There are the following methods to adjust the pad surface:

1) Intuitive method (experience plus and minus pad method). Because in the maintenance, the alignment of some pumps does not have good conditions and tools, the experience of the master will play a big role in the adjustment, and the tightness of the motor bolts should be considered every time the pad is added or subtracted. and the remainder.

2), calculation method.

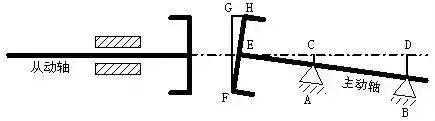

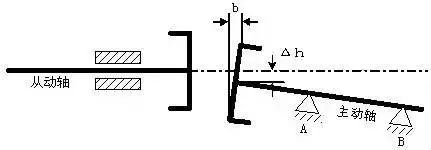

Ⅰ. Original state

Ⅱ. Increase Δh

Ⅲ. Adjusted axis line

(1), first eliminate the height difference of the coupling

The motor shaft should be raised up by Δh with gaskets, which means that the front support A and the rear support B should be cushioned by Δh under the seat at the same time.

(2) Eliminate the opening of the coupling

Add gaskets of different thicknesses under the A and B supports respectively, and the pad added to the B support should be a little behind that of the A support.

Therefore, the thickness of the total adjusting gasket is: front support A=Δh+AC; rear support B=Δh+BD. (Among them, you can think about the calculation methods of AC and BD, how to get them through measurable data.)

Attached:

Pump coupling finding center deviation standard (unit: mm)

|

Rotating speed |

rigidity |

elasticity |

|

≥3000 |

≤0.02 |

≤0.04 |

|

<3000 |

≤0.04 |

≤0.06 |

|

<1500 |

≤0.06 |

≤0.08 |

|

<750 |

≤0.08 |

≤0.10 |

|

<500 |

≤0.10 |

≤0.15 |

Face-to-face distance of pump coupling

|

large |

8-12mm |

|

medium |

6-8mm |

|

small |

3-6mm |

XINDA

XINDA