What determines the life of the motor?

Knowing how to use a product properly can have a huge impact on its performance and longevity. For example, knowing how to properly maintain cast iron pans can make them last longer. For electric motors, understanding the factors that affect motor life is the first step to extending life and reducing costs in the long run.

First, what determines the end of life?

Usually, end of life means that the product is no longer valid. However, what exactly does this mean?

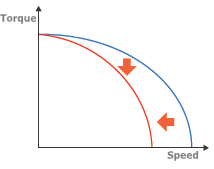

The end of life means that the speed, torque, accuracy, etc. described in the specification cannot be exhibited. This means the motor will still work, but not to specification. If the product does not meet its intended specifications, the job cannot be done. If it can't do its job, it's "dead" to us.

Torque and speed decrease as the motor approaches the end of its life due to wear.

What are the main factors affecting life expectancy?

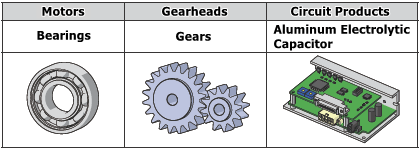

The life of a product is often determined by the first component to fail. The 3 main components most likely to fail first are bearings, gears, and electrical products such as drives and controls .

bearing

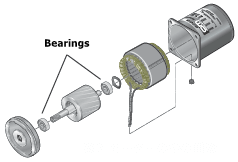

Bearings are machine parts that limit unwanted movement and reduce friction between two moving parts. In electric machines, bearings support the load shaft and rotor. Since damaged bearings can cause the motor to stop running, they are considered critical components.

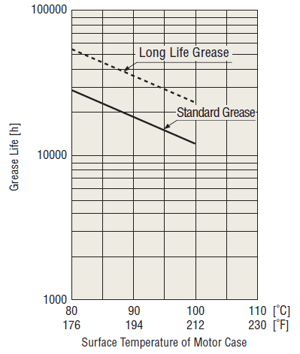

Standard motor life is estimated based on temperature-dependent bearing grease life. Exceeding the specifications of the motor, such as radial (cantilever) loads and axial (thrust) loads can also result in shortened life. Motors that use long-life bearing grease can extend their service life to approximately 10,000 hours of operation.

gear

Gears are used to reduce the speed of the motor and increase the torque. Torque is multiplied by the ratio (and gear efficiency) between gears, and speed is reduced through the ratio. Like bearings, gears are directly subjected to loads and will eventually wear out; especially when subjected to shock loads, or if the motor specifications are exceeded. Once worn, the motor will still work, but the kickback and noise will no longer meet its specifications.

circuit products

Circuit products include drivers that provide logic and current to stepper or servo motors , and controllers that provide logic instructions to the drivers. Components in circuit products, such as electrolytic capacitors , may fail due to high temperatures. The life of a circuit product depends on the life of its electrolytic capacitor.

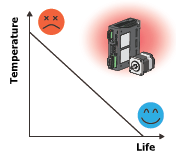

Prompt: How exactly does temperature affect longevity?

Motor life is affected by many factors such as deterioration of insulation, sliding parts and bearings. In most cases, motor life depends on bearing life, bearing life depends on grease life, and grease life depends on temperature. Rolling fatigue also affects bearing life, but not as much as temperature. Long-life grease keeps bearings in service longer.

If the bearing temperature increases by 15° C (27° F), its life will be cut in half. Not only grease, but temperature rise suppression of electronic components is also important. For example, the life of an electrolytic capacitor is cut in half when the ambient temperature rises by 10°C (18°F).

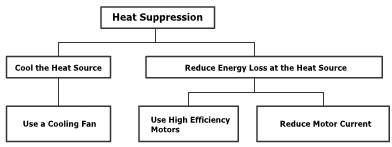

So how to control the temperature rise?

There is a way to cool a heat source, and there is a way to reduce the amount of heat a heat source produces. Cooling heat sources, cooling fans, heat dissipation (mounting to larger metal plates, heat dissipation) are all ways to reduce the temperature. Lowering the operating temperature of the motor can extend the life of the motor because the bearing grease will last longer. Reducing the temperature at which the motor is operated can also increase its duty cycle. I have supported an application where the duty cycle of a stepper motor was increased to close to 100% using a water-circulating cooling jacket.

Another way is to reduce the energy loss of the motor. Since energy loss is in the form of heat, reducing energy loss also reduces temperature. In this case we can use high efficiency motors or continuous duty motors. For stepper motors and servo motors, reducing the motor current also reduces their operating temperature. This is because current is directly proportional to temperature. However, current is also directly proportional to torque, so the ideal is to reduce the current to a level that still produces sufficient torque, but do so at the lowest possible operating temperature.

XINDA

XINDA