The motor slot full rate and the copper full rate are a bit silly to distinguish?

What is slot fill rate?

That is, the ratio of the cross-sectional area of the conductor in the iron core slot to the total area of the iron core slot, the higher the motor slot full rate means "the more copper wires are filled in the iron core slot".

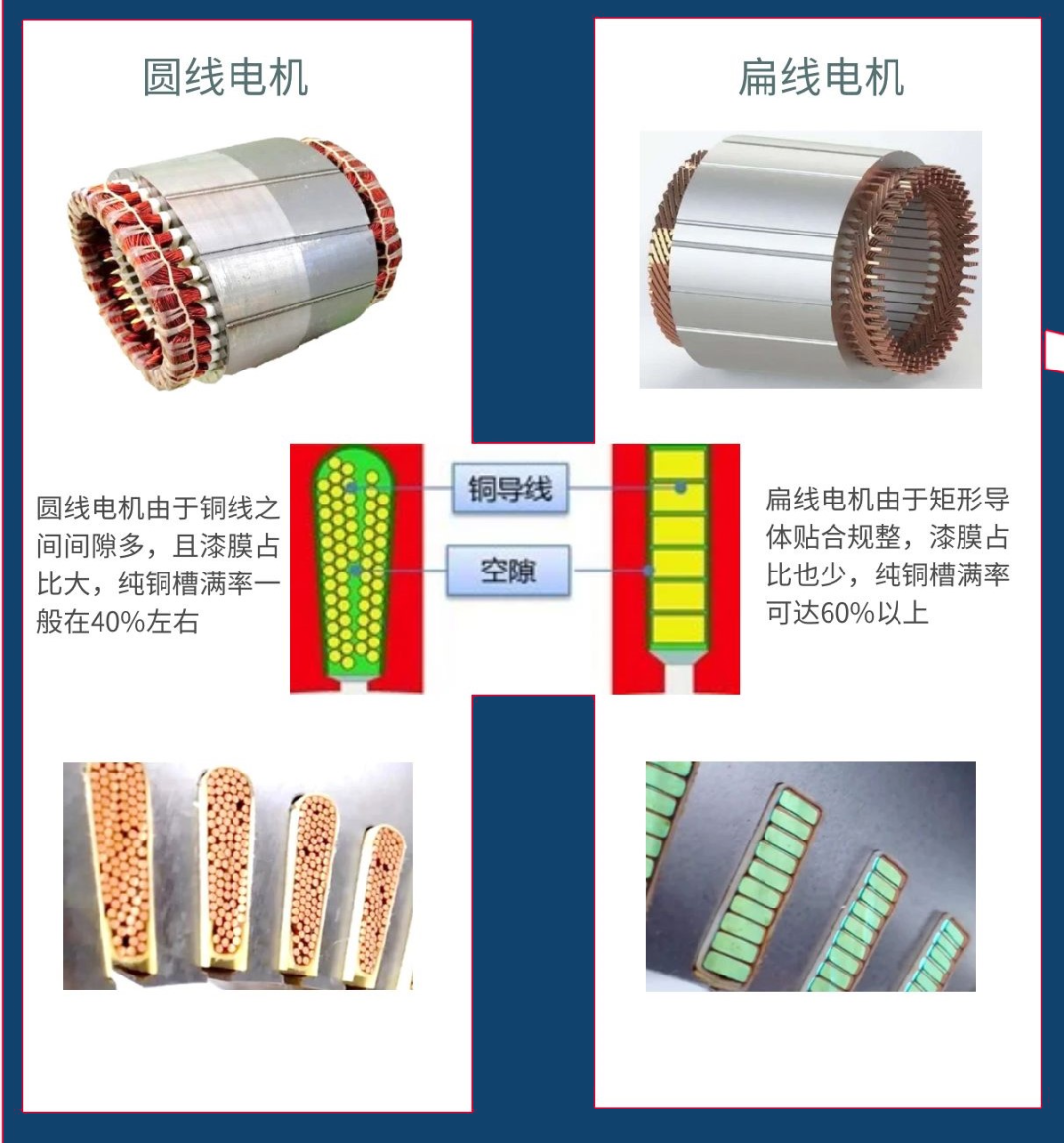

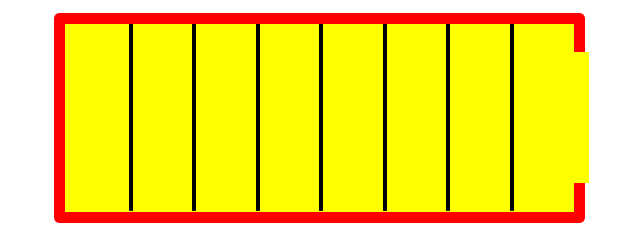

Slot full rate comparison diagram

As can be seen from the above figure, flat wire motors have become the absolute mainstream of new energy drive motors due to the substantial increase in slot fill rate. From the product point of view, of course, the higher the slot full rate, the better, but on the other hand, the continuous improvement of the slot full rate has brought huge challenges to the manufacturing process and equipment precision/complexity of flat wire motors.

Slot fill factor (English: slot fill factor, taken from the motor simulation software Maxwell), most of them think that the slot fill factor refers to the ratio of the effective area of the slot after the coil is placed in the slot. The ratio of the cross-sectional area occupied by the copper wire to the total space in the bare slot, the difference between the two is whether to take into account the insulating layer, insulating paper and other materials wrapped by the copper wire. I personally think that the latter may be more like copper full rate, but both calculations are fine, because the simple calculation of the two methods will not have a substantial impact on the performance of the motor, but in the comparison of motor performance, it is still necessary unified calculation method.

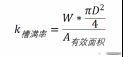

So what is the formula for calculating the slot full rate? Let's take the calculation of the tank full rate considering the insulating material as an example, the calculation formula is:

Wherein, W is the total number of wires in a single slot;

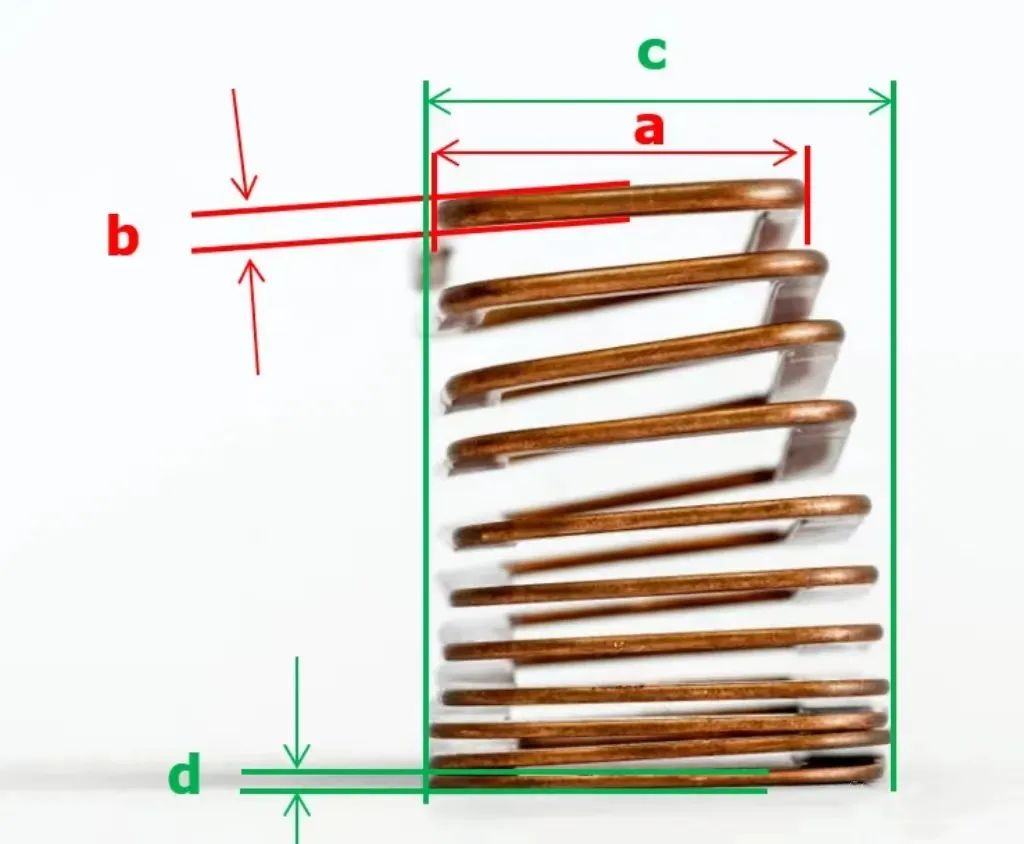

D is the diameter of the wire (including the enameled wire layer), as shown in the figure below;

A The effective area is the total area of the bare slot minus the area of the slot insulation (such as insulating paper, etc.).

wire

It is generally believed that the slot full rate is 75%-80%, not more than 80%, because a high slot full rate has an adverse effect on the heat dissipation of the coil. Of course, this is the solution that can be used when initially setting the slot full rate. In the final verification process The slot full rate can be lower than this value, but higher than this value is not recommended. It can be seen from the above formula that there are many ways to improve the slot fullness rate, such as increasing the diameter of the wire and reducing the effective area of the slot. However, the adjustment of the coil slot fullness rate has almost no impact on the performance of the motor, which may be related to the embedding. Depends on the difficulty of the line. Therefore, generally speaking, increasing the slot fullness rate generally refers to placing as many turns as possible in the core slot, that is, increasing W (the total number of wires in a single slot).

Motor slot full rate model

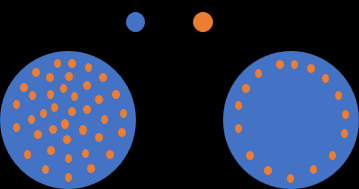

How does increasing the slot full rate affect the motor? First of all, there are many ways to increase the slot full rate, here only refers to increasing the number of coil turns to increase the slot full rate; secondly, increasing the slot full rate of the motor can increase the power of the motor, and shorten the length of the motor at the same power ; finally, Improving the slot full rate of the motor can reduce a considerable part of copper wires, silicon steel sheets, ferromagnetic materials , etc., and increase the utilization rate of motor materials. A relatively appropriate slot full rate can effectively increase the proportion of effective materials and reduce the material cost of the motor.

The effect of the slot fullness on the skin effect of the motor wire? Then, the conductor skin effect - when the conductor passes through the alternating current, the current distribution on the conductor section is uneven, the current density gradually increases from the conductor center to the surface, and most of the current only flows along the surface of the conductor. A physical phenomenon, As shown below.

Simplified skin effect

Of course, the improvement of the slot fullness also increases the difficulty for the manufacture of the flat wire stator.

First of all, there are high requirements for the precision and consistency of copper wire forming. When the copper wire is formed, it is impossible to be completely consistent with the theoretical digital model line shape, and there are errors and fluctuations in the contour and straightness. Therefore, compared with the 3D digital model, a set of copper wires in the slot is not so regular when inserted. This kind of irregularity will obviously increase the friction resistance when the copper wire enters the iron core slot, and a greater pressing force is needed to overcome it, and excessive pressing force will lead to improper insertion, extrusion deformation or damage of copper wire, sliding of insulating paper, etc. series of questions. The higher the slot fill rate, the smaller the design clearance in the core slot and the lower the tolerance for this irregularity.

Secondly, all the mechanisms and parts related to the centering and guiding of the equipment require high precision. When the hairpin is inserted into the iron core, all slots (48, 54, 72...) need to be precisely aligned with the iron core slot at the same time, so that the copper wire can smoothly enter the iron core slot. The higher the slot fullness, the higher the alignment accuracy requirements.

Furthermore, there is an increased risk of the insulating paper slipping when entering the wire. A high slot fullness rate means that the friction between the copper wire and the insulating paper increases when the wire is inserted, and the insulating paper is easily driven by the friction to slide axially. It is necessary to make the envelope size of the insulating paper as large as possible, and at the same time support the bottom of the insulating paper during the wire insertion and crimping process.

RIO Electric Drive consulted relevant experts. There are some differences between the slot full rate and the copper full rate. The slot full rate is the area occupied by the copper wire in the slot. The insulation on the copper wire is not removed during the calculation. The copper full rate is the ratio of pure copper to the slot area calculated after removing the insulation on the copper wire.

Fraunhofer IWU (German Fraunhofer Institute of Machine Tool and Forming Technology) processes flat copper wires using a new metal forming production process, which can greatly increase the motor stator copper full rate (non-slot full rate) from 50% to 80% .

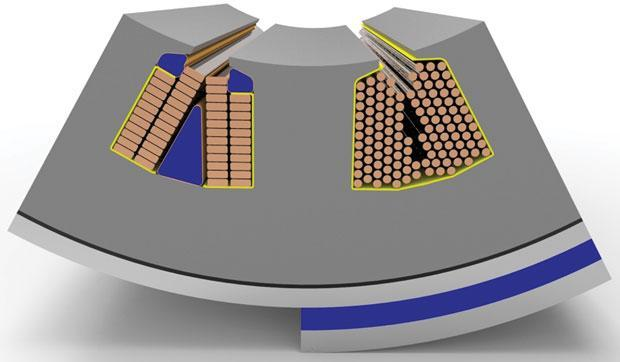

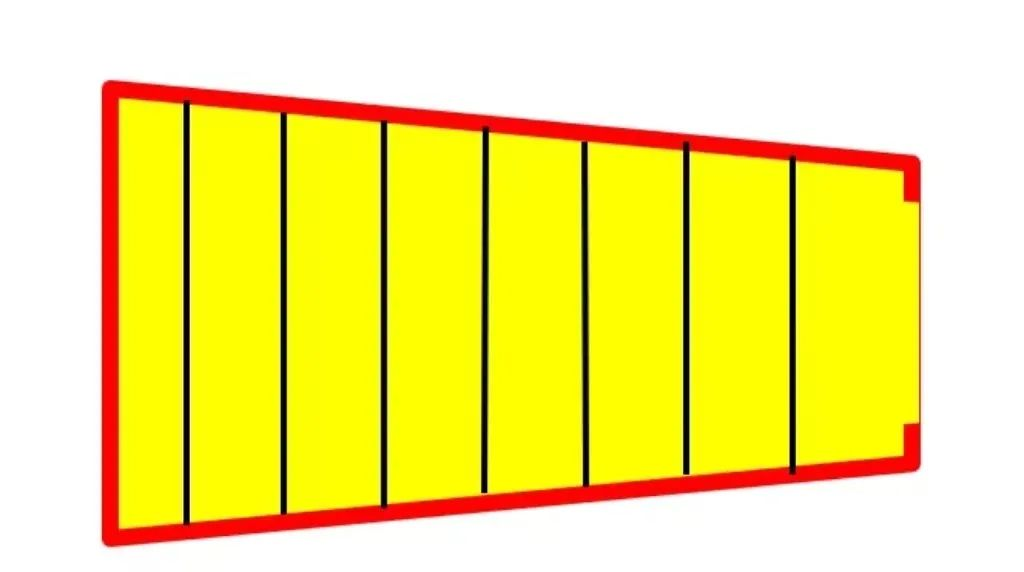

Usually, the stator slot of the flat wire motor is a rectangular slot, and insulating paper is inserted in the slot, and the copper wire coated with an insulating layer (PEEK, PI, etc.) is inserted into the rectangular slot and then potted and fixed. In order to fit the rectangular slot, the cross section of the copper wire is It is also rectangular, and the nominal size (length x width) of each wire section of each layer is the same, as shown in the figure below.

Conventional flat wire motor rectangular slot

Different from the rectangular slots of common flat-wire motors, Fraunhofer IWU designed the stator slots of the motor as trapezoidal, and the corresponding copper wires have also been specially designed: the copper wires are designed with variable cross-sections. In order to maintain the same current-carrying capacity, each layer of copper wires is cut The areas are all equal, but the upper and lower bases and heights of the trapezoidal section are not equal. The closer to the motor axis, the narrower and thicker it is, and the farther away from the motor axis, the wider and thinner it is, as shown in the figure below.

Flat wire motors with trapezoidal slots

Winding with variable cross-section

The picture above is a display sample, and it can be clearly seen that the upper copper wire is narrower and thicker than the bottom copper wire (ad). Through the application of trapezoidal slots, the internal space of the motor can be utilized to the maximum, and a larger current can be achieved under the premise that the overall outer envelope remains unchanged, thereby improving the power density and torque density of the motor.

The variable cross-section flat wire forming technology introduced by the Fraunhofer IWU Institute can not only significantly improve the performance of the motor, but also greatly reduce the waste of materials, and the entire process will hardly generate waste.

XINDA

XINDA