The functions of carbon brushes in different motor types

In wound-type induction motors and brushed DC motors, the carbon brush is a very critical electrical component, that is, through a good dynamic connection, it solves the circuit composition during the operation of the motor. However, the function of carbon brushes is still different for different motor types.

For the wound rotor induction motor, the electromotive force of the rotor part of the motor is obtained according to the principle of electromagnetic induction. The function of the carbon brush of the motor is mainly to connect an external starting resistor, that is, to improve the starting performance of the motor by connecting an external resistor in series. When there is no external resistance, different phase windings can be short-circuited at the brush holder to form a closed circuit for the normal operation of the rotor, and the motor can start and run, but the starting current is relatively large in this state, which is also the case for this type of motor. The actual state of the test.

For a brushed DC motor, the function of the carbon brush is to realize the power supply of the armature winding of the rotor through dynamic connection, that is, to play the role of connecting the power supply.

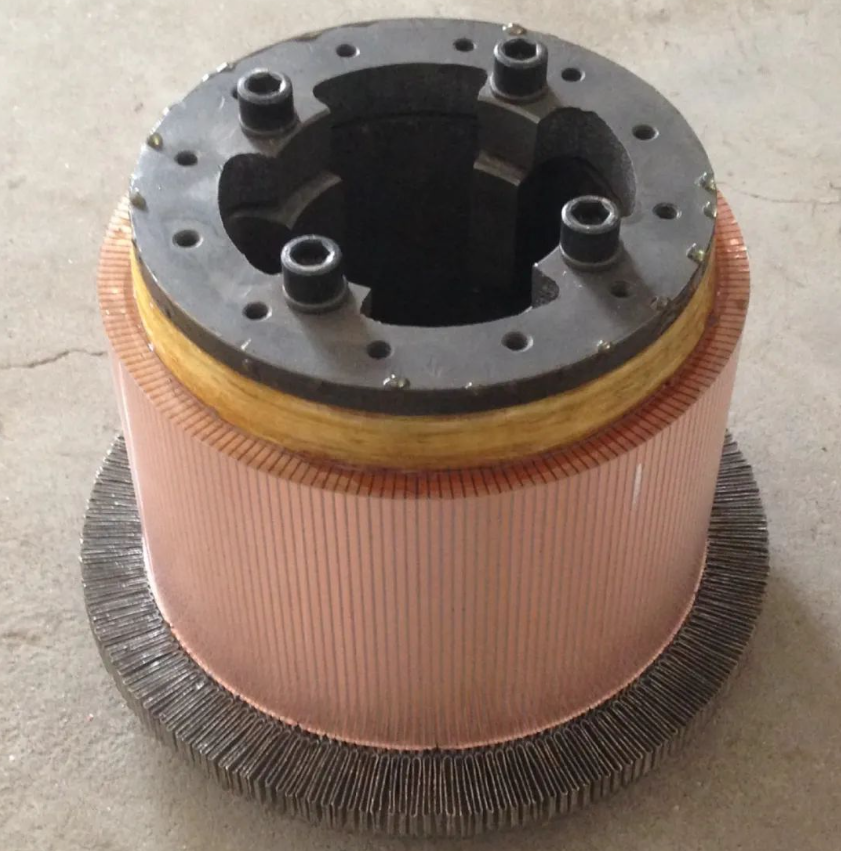

However, for different motor carbon brushes, the common function is the connection structure of the electrical circuit, the conductivity of the carbon brush, and the connection effect of the carbon brush system, which directly affect the operating quality of the motor. In order to ensure the overall operation quality of the motor, the carbon brush, as an important connecting part, is a kind of wearing part, and regular maintenance and replacement are necessary. In the actual installation process, the contact area between the carbon brush and the collector ring or commutator is a key factor. The radian of the carbon brush is consistent with the arc of the conductive ring. In the installation process of such parts, The contact area between the two is required to reach more than 70%, otherwise it is prone to heating problems.

In the application cases of this type of motor, problems such as severe wear of the conductive ring and severe ablation of the conductive ring due to various reasons abound, which have a great relationship with the dynamic connection system including carbon brushes. Therefore, for this Whether it is in the production or maintenance of the motor, it is the key to accurately grasp the assembly relationship of the relevant parts and choose the appropriate material.

XINDA

XINDA