![]() Generally, at what temperature can the motor work normally? What is the maximum temperature the motor can withstand?

Generally, at what temperature can the motor work normally? What is the maximum temperature the motor can withstand?

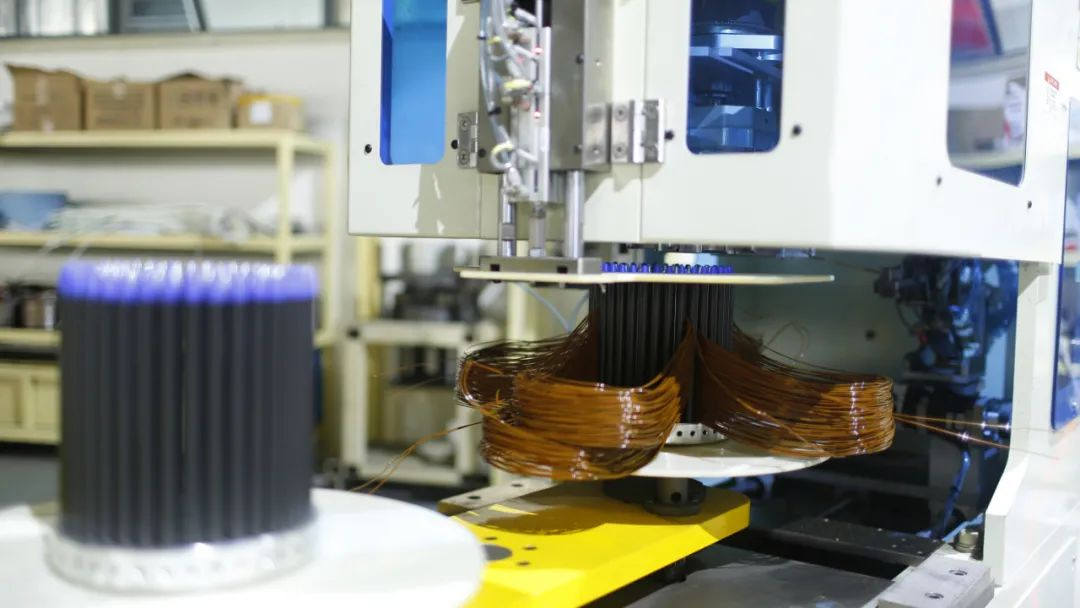

Answer: If the measured temperature of the motor cover exceeds the ambient temperature by more than 25 degrees, it indicates that the temperature rise of the motor has exceeded the normal range. Generally, the temperature rise of the motor should be below 20 degrees. Generally, the motor coil is made of enameled wire, and when the temperature of the enameled wire is higher than about 150 degrees, the paint film will fall off due to the high temperature, resulting in a short circuit of the coil. When the coil temperature is above 150 degrees, the motor casing exhibits a temperature of about 100 degrees, so if the casing temperature is used as the basis, the maximum temperature the motor can withstand is 100 degrees.

The temperature of the motor should be below 20 degrees Celsius, that is, the temperature of the motor end cover should exceed the ambient temperature by less than 20 degrees Celsius, but what is the reason for the motor to heat more than 20 degrees Celsius?Answer: The direct cause of the motor heating is due to the large current. Generally, it may be caused by short circuit or open circuit of the coil, demagnetization of the magnetic steel or low efficiency of the motor. The normal situation is that the motor runs at a high current for a long time. What causes the motor to heat up? What kind of process is this?Answer: When the motor is running under load, there is power loss in the motor, which will eventually turn into heat energy, which will increase the temperature of the motor and exceed the ambient temperature. The value by which the motor temperature rises above the ambient temperature is called warm-up. Once the temperature rises, the motor will dissipate heat to the surroundings; the higher the temperature, the faster the heat dissipation. When the heat emitted by the motor per unit time is equal to the heat dissipated, the temperature of the motor will not increase, but maintain a stable temperature, that is, in a state of balance between heat generation and heat dissipation.

What is the allowable temperature rise of the general motor? Which part of the motor is most affected by the temperature rise of the motor? How is it defined?

Answer: When the motor is running under load, from the perspective of exerting its function as much as possible, the higher the load, that is, the output power, the better (if mechanical strength is not considered). However, the greater the output power, the greater the power loss, and the higher the temperature. We know that the weakest temperature-resistant thing in the motor is the insulating material, such as enameled wire. There is a limit to the temperature resistance of insulating materials. Within this limit, the physical, chemical, mechanical, electrical and other aspects of insulating materials are very stable, and their working life is generally about 20 years.

If this limit is exceeded, the life of the insulating material will be shortened sharply, and it may even be burned. This temperature limit is called the allowable temperature of the insulating material. The allowable temperature of the insulating material is the allowable temperature of the motor; the life of the insulating material is generally the life of the motor.

Excessive temperature is one of the common fault types of motors, so what causes the temperature of the motor to be too high?The following are the common causes and treatment methods of high motor temperature:1. When the instantaneous voltage of the motor exceeds the rated voltage by more than 10%, or the instantaneous voltage of the motor is lower than the rated voltage by more than 5%, it will cause the motor to generate heat and temperature rise under the rated load. In this case, the voltage should be checked and adjusted.2. The unbalance of the three-phase power supply voltage of the motor will also cause the motor to heat up. This is because when the unbalance of the three-phase power supply voltage exceeds 5%, it will cause the unbalance of the three-phase current. The countermeasure is to check and adjust the voltage.

3. The contact problem of the power switch of the motor and the open circuit of one-phase fuse will cause the lack of phase operation, which will cause the temperature of the motor to rise. The solution is to repair or replace the damaged parts.4. There is an error in the winding wiring of the motor, which causes the motor running under the rated load to overheat. The solution is to correct the wiring error of the winding wire.5. The stator winding of the motor is short-circuited or grounded between turns or phases. Such a situation will cause the current of the motor to increase and the temperature to rise. The solution is to add insulation to the center or directly replace the winding.6. The broken bars of the cage rotor of the motor or the loosening of the coil joints of the wound rotor will cause the current of the maintenance network to increase and cause the temperature to rise. The countermeasure is to repair or replace the rotor.7. When the bearings of the motor are severely worn, there will be large friction and heat generation. The solution is to check whether the bearings are loose and whether the stator and rotor are not well matched.8. Excessive load of the motor is also the cause of overheating. Reducing the load or replacing a high-power motor can solve the overheating problem.9. Too frequent starting of the motor, high ambient temperature, poor ventilation, etc. will also cause the temperature of the motor to be too high. Reducing the number of starts, lowering the ambient temperature, ensuring the smooth flow of the air duct, eliminating dust and oil, and keeping the fan running well can help solve similar overheating problems.For a running motor, if the current does not exceed the rated current of the motor, it means that there is basically no problem in the circuit. If the original load has not been changed, it is necessary to check whether the voltage is higher than the rated voltage. Generally, 380V is plus or minus 5%. See if the ambient temperature is too high. Whether the bearing is short of oil. Whether the cooling fan is damaged.(1) The load is too large. The load should be reduced or a motor with a larger capacity should be replaced.(2) Two-phase operation. Check whether the fuse is blown, whether the contact point of the switch is in good contact, and troubleshoot;(3) The air duct of the motor is blocked. Air duct dust or grease should be removed;(4) The ambient temperature rises. Cooling measures should be taken;(5) Turn-to-turn or phase-to-phase short circuit of the stator winding. Use a megohmmeter or multimeter to check the insulation resistance between the two-phase windings; use the current balance method to check the three-phase winding current, the phase with a large current is a short-circuit phase, and a short-circuit detector can also be used to check whether there is a short circuit between the turns of the winding;(6) The stator winding is grounded. It can be checked with a multimeter or an indicator light, and the phase with zero resistance is the ground phase;(7) The power supply voltage is too low or too high. Use the voltage range of the multimeter or a voltmeter to check the power supply voltage at the motor input terminal. Causes of motor overheating:

1. The bearing is not working properly, which will definitely cause the motor to heat up

Whether the bearing is working normally can be judged by hearing and temperature experience.

You can use your hand or a thermometer to test the bearing end to determine whether its temperature is within the normal range; you can also use a listening rod (copper rod) to touch the bearing box. If you hear an impact sound, it means that one or several balls may be crushed. If you hear a hissing sound, it means that the lubricating oil of the bearing is insufficient.

2. The power supply voltage is too high, the excitation current increases, and the motor will overheat

Excessive voltage can compromise the motor insulation, putting it at risk of breakdown. When the power supply voltage is too low, the electromagnetic torque will decrease. If the load torque does not decrease and the rotor speed is too low, the increased slip will cause the motor to be overloaded and heat up. Long-term overload will affect the life of the motor. When the three-phase voltage is asymmetrical, that is, when the voltage of one phase is high or low, the current of a certain phase will be too large, and the motor will heat up. At the same time, the torque will decrease and the "humming" sound will be emitted. After a long time, the winding will be damaged.In short, no matter whether the voltage is too high, too low or the voltage is asymmetrical, the current will increase, and the motor will heat up and damage the motor. Therefore, according to the national standard, the change of the power supply voltage of the motor should not exceed ±5% of the rated value, and the output power of the motor can maintain the rated value. The motor power supply voltage is not allowed to exceed ±10% of the rated value, and the difference between the three-phase power supply voltages should not exceed ±5% of the rated value.

3. The abnormal vibration or noise of the motor can easily cause the motor to heat up

This kind of situation belongs to the vibration caused by the motor itself, most of which are caused by poor dynamic balance of the rotor, poor bearing, bent shaft, different shaft centers of the end cover, machine base, and rotor, loose fasteners, uneven foundation of the motor installation, and improper installation.

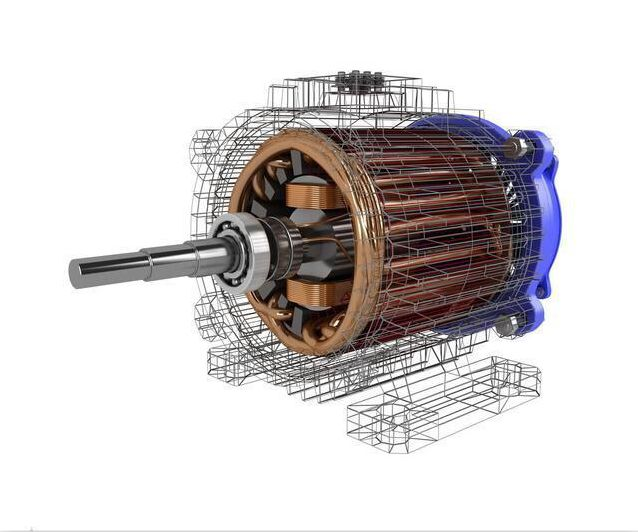

4. The air gap between the stator and rotor of the motor is very small, which may easily lead to collision between the stator and rotor

In medium and small motors, the air gap is generally 0.2mm to 1.5mm. When the air gap is large, the excitation current is required to be large, thereby affecting the power factor of the motor; if the air gap is too small, the rotor may rub or collide. Generally, due to the serious out-of-tolerance of the bearing and the wear and deformation of the inner hole of the end cover, the different axes of the machine base, end cover and rotor will cause bore sweeping, which will easily cause the motor to heat up or even burn out. If the bearing is found to be worn, it should be replaced in time, and the end cover should be replaced or brushed. The simpler treatment method is to inlay the end cover.

5. Almost more than half of the motor burnt is caused by the lack of phase operation of the motor

The lack of phase often causes the motor to fail to run or the speed is slow after starting, or there is a "humming" sound when the rotation is weak and the current increases. If the load on the shaft does not change, the motor is seriously overloaded, and the stator current will reach 2 times the rated value or even higher. The motor will heat up or even burn out in a short time.The main reasons for the lack of phase operation are as follows:

If one phase loses power due to other equipment failures on the power line, other three-phase equipment connected to the line will run without phase.

One phase of the circuit breaker or contactor is open due to bias voltage burnout or poor contact.

The motor is connected to the incoming line due to aging, wear and other reasons.

One-phase winding of the motor is broken, or one-phase connector in the junction box is loose.

6. The material leaks into the motor, which reduces the insulation of the motor, thereby reducing the allowable temperature rise of the motor

If solid material or dust enters the motor from the junction box, it will reach the air gap between the stator and rotor of the motor, causing the motor to sweep, until the insulation of the motor winding is worn out, and the motor is damaged or scrapped. If liquid and gaseous media leak into the motor, it will directly cause the insulation of the motor to drop and trip.General liquid and gas leakage has the following manifestations:

Leakage of various containers and delivery pipelines, leakage of pump body seals, flushing of equipment and the ground;

mechanical oil leaks into the motor from the gap in the front bearing box; the oil

seal of the reducer connected to the motor is worn, and the mechanical lubricating oil enters along the motor shaft.

7. Winding short circuit, turn-to-turn short circuit, phase-to-phase short circuit and winding open circuit

After the insulation between two adjacent wires in the winding is damaged, the two conductors touch each other, which is called winding short circuit. Winding short circuits that occur in the same winding are called turn-to-turn short circuits. A winding short circuit that occurs between two phase windings is called a phase-to-phase short circuit. No matter which one it is, it will increase the current of one phase or two phases, cause local heating, and age the insulation to damage the motor. Winding open circuit refers to the failure caused by the stator or rotor winding of the motor being broken or blown. Whether it is a short circuit or an open circuit of the winding, it may cause the motor to heat up or even burn out. Therefore, it must be shut down immediately after this happens.

8. Other reasons for non-mechanical and electrical failures

The temperature rise of the motor caused by other non-mechanical and electrical faults may also lead to motor failure in severe cases. If the ambient temperature is high, the motor lacks a fan, the fan is incomplete, or the fan cover is missing. In this case, it is necessary to force cooling to ensure ventilation or replace fan blades, otherwise the normal operation of the motor cannot be guaranteed.

In order to use the correct method to deal with motor faults, it is necessary to be familiar with the characteristics and causes of common motor faults, grasp the key factors, check and maintain regularly, so as to avoid detours, save time, eliminate faults as soon as possible, and keep the motor in normal operation. In order to ensure the normal production of the workshop.

XINDA

XINDA