Is the difference between DC and AC really that big?

Different types of household appliances are used in different occasions, and the requirements for motors are also different. And there are not only differences in size and performance between motors and motors, but also differences in structure, characteristics and even working principles, so there are more cases of "special purpose".

Although the theoretical basis of the motor is the magnetic effect of current and the phenomenon of electromagnetic induction, from the perspective of the history of motor development, there are many differences in the form of motors for different power types.

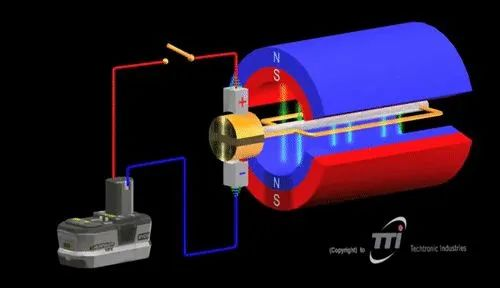

In the era before Faraday and Oster, the only power source that humans could use was the silver-zinc battery invented by Volt, and the earliest practical ones were DC generators and DC motors. The most unique structure of a DC motor is the commutator and brushes, which switch the direction of the current as the coil rotates, allowing the rotor to continue to rotate under force.

Principle of DC motor

Due to the first application of DC generators and motors, people even thought that DC power was the power source suitable for large-scale use in the future. Everyone knows what happened later. The AC system has become the mainstream today because of its small transmission loss and easy voltage change.

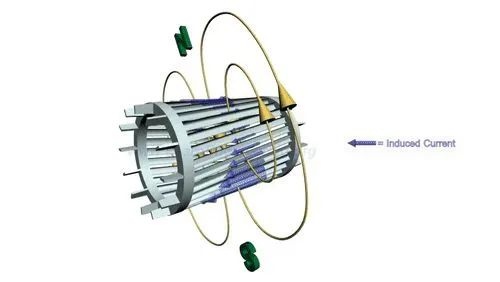

After the appearance of the practical alternator, the alternator came into being. The stator winding generates a rotating magnetic field through alternating current, and the rotor winding generates an induced current in the changing magnetic field, and rotates with the rotating magnetic field.

AC motors do not require commutators and brushes to change the direction of current. Compared with DC motors, they have a simpler structure and higher power, and are widely used in industrial fields.

Induction AC Motor Principle

Of course, motors have developed to this day, and there are many ways to classify them. They can be classified according to the excitation method, or according to the speed and power, but they can be divided into DC motors and AC motors according to the type of working power supply.

In our daily life, we use 220V alternating current, and also use the DC power inverted by batteries or power adapters, so DC motors and AC motors often exist at the same time.

For electrical appliances in different applicable occasions, it is necessary to consider the characteristics including speed, torque, power, size, speed regulation performance, life, etc. to select the appropriate motor type.

For example, in air conditioners and refrigerators, the function of the motors of both is to drive the compressor to cool down. Since both require long-term operation, most of them have higher requirements for the efficiency of the motors, but there are also some differences.

If the refrigerator is indoors and the main unit of the air conditioner is outdoors, the requirements for operating noise will be different; the cooling space of the refrigerator is calculated in liters, while the air conditioner is calculated in cubic meters (because the floor height is relatively fixed, it is actually calculated in square meters), so the latter requires higher power requirements. Most refrigerators and air conditioners on the market use AC motors.

For small household appliances such as electric toothbrushes and shavers, the first consideration must be portability. They are often powered by batteries and driven by small DC motors, which are very different from the motors used in refrigerator air conditioners.

There are also some household appliances that can use both DC motors and AC motors. The food waste processor that has gradually entered the public eye due to garbage classification is a typical example.

The food waste disposer is a modern appliance installed under the kitchen sink. It can grind and pulverize wet waste such as melon peels, rotten leaves of vegetable stems, and broken shrimp shells and bones into fine particles and discharge them directly into the sewer, eliminating the need for cumbersome steps such as cleaning up and bagging the waste.

How Food Waste Disposers Work Source: YouTube InSinkErator Channel

The food waste disposer may be new to us, but it's actually been around for over 80 years. In 1927, architect Mr. John Hammers invented the world's first food waste disposer for his wife, and then he perfected the design to commercialize it and established the InSinkErator brand.

For food waste disposers, the motor is the core component, which directly affects the user experience. The difference between the performance parameters of DC motors and AC motors is relative, and the performance differences between different DC motors can also be large. However, the difference in some characteristics of DC motors and AC motors is absolutely there.

DC motors have a wide range of speed regulation and can be small in size. They are usually used in small household appliances such as shavers and electric toothbrushes in the household field, which is difficult for AC motors to achieve.

The structure of the AC motor does not have the friction loss of the commutator and the brush, and the noise generated is even smaller. It does not need regular maintenance like the DC motor, which is what the DC motor lacks. The speed of the AC motor is stable, the reliability is high, and the life is longer. Therefore, durable appliances such as washing machines, air conditioners, refrigerators, and fans mostly use AC motors.

For food waste disposers, which are permanently installed and used for a long time, motors with low noise and long life can provide a better experience. Perhaps this is one of the reasons why InSinkErator has insisted on using AC motors for more than 80 years.

Another reason is that InSinkErator became a brand of Emerson in 1968, and Emerson is the world's leading manufacturer of electric motors. The Dura-Drive induction AC motor used by InSinkErator has high torque, long life, quieter and safer, which is naturally derived from Emerson's advanced technology.

Both are motors, and different usage scenarios have different requirements. For a certain type of electrical appliance, a DC motor may be a better choice, and for another type of electrical appliance, an AC motor may be a better choice.

As a consumer, it is difficult to understand the principles and parameters of these key components, but it is useful. At least we can roughly judge whether the manufacturer really considers the user experience of the product. Some manufacturers can independently develop and design key components for the product, while others only integrate mainstream solutions.

Sometimes we care too much about comparing the so-called "cost-effectiveness" and choose "value-for-money" products based on the price and parameters. But if you don't understand the technical principles behind it, it's easy to ignore the deep differences like DC motors and AC motors. While understanding the parameters, don't ignore the technology behind the parameters.

References:

[1] Shang Qingyuan, Qian Liangchai, Hu Kangyin. Application of motors, Lecture 3: Application of motors in household appliances (1) [J]. Micromotor (Servo Technology), 2002(01): 52-53+59.

[2] Shang Qingyuan, Qian Liangchai, Hu Kangyin. Application of motors, Lecture 3: Application of motors in household appliances (2) [J]. Micromotor (Servo Technology), 2002(02): 47-49.

[3] Chen Bao. Development Status of Small Motors for Household Appliances [J]. Electrical Appliance Manufacturer, 2001(01):58-59.

[4] Yan Lairong. Application and Business Opportunities of Motors in Modern Household Appliances [J]. Electrical Appliance Technology, 2005(06):64-67.

XINDA

XINDA