How to use a multimeter to detect whether the motor is burnt out

Electric motors are widely used devices in modern industry and households to drive various mechanical devices. However, motors can burn out or fail for various reasons. Using a multimeter can help us monitor the health of the motor. The following will introduce how to use a multimeter to detect whether the single-phase motor and the three-phase motor are burnt out.

1. Check whether the single-phase motor is burnt out

Preparation:

Be Safe: Before performing any electrical testing, be sure to disconnect power and use insulated gloves and insulated tools for personal safety.

Backup power source: Prepare a reliable backup power source, such as a battery or generator, to provide power to the motor.

To test winding continuity:

Disconnect from power supply: Make sure the motor is disconnected from the power supply and disconnect the motor from the power supply.

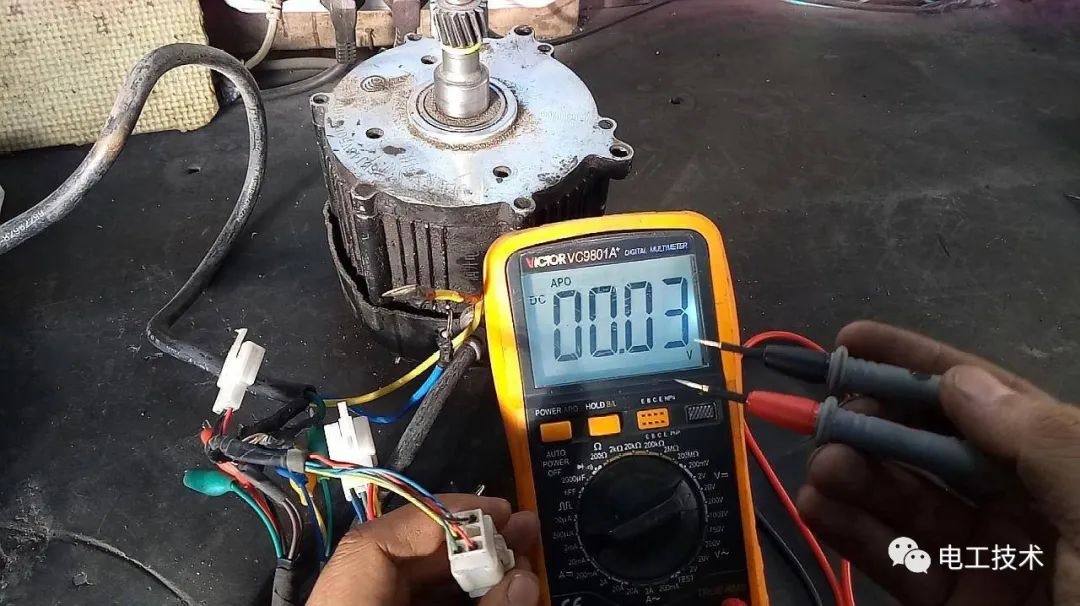

To set up the multimeter: turn the multimeter to the resistance measurement mode and select an appropriate range.

Test the start winding: Connect one test lead to one terminal of the motor and the other test lead to each other terminal and observe the reading on the multimeter. If the reading is close to zero, there is continuity between the windings and the motor windings are fine.

Repeat the test: Repeat the above steps to test the continuity between each winding of the motor. If there is no continuity or an abnormal reading between any two windings, it may indicate a burned out motor winding.

Test winding insulation:

Prepare the test leads: Connect one test lead to the motor's windings and the other to the motor's metal case or ground.

To set up the multimeter: turn the multimeter to the resistance measurement mode and select the appropriate range.

Test insulation resistance: observe the reading of the multimeter. If the reading is very high (typically several megohms or higher), the motor's insulation is fine. If the reading is low or close to zero, it may indicate that the motor's insulation has burned out.

Test the motor rotor:

Prepare the test leads: Connect one test lead to the motor's rotor and the other lead to the motor's metal case or ground.

To set up the multimeter: turn the multimeter to the resistance measurement mode and select the appropriate range.

Test the rotor insulation: Observe the reading on the multimeter. If the reading is very high (typically several megohms or higher), it means that the motor's rotor insulation is fine. If the reading is low or close to zero, it may indicate that the motor's rotor insulation has burned out.

Test capacitors (if applicable):

Make sure the capacitor is present: Check if the motor has a capacitor. If there is a capacitor, it is usually marked on the motor.

Prepare the test leads: Connect one test lead to one pin of the capacitor and the other lead to the other pin of the capacitor.

To set up the multimeter: turn the multimeter to the capacitance measurement mode and select the appropriate range.

Test the capacitance value: observe the reading of the multimeter. It should be close to the rated capacitance marked on the capacitor. If the reading deviates significantly from the rated capacitance or approaches infinity or infinity, it may indicate a burned out capacitor.

2. Check whether the three-phase motor is burnt out

Preparation:

Be Safe: As with single-phase motors, be sure to disconnect power and use insulated gloves and insulated tools for handling.

Backup power source: Prepare a reliable backup power source, such as a battery or generator, to provide power to the motor.

To test winding continuity:

Disconnect from power supply: Make sure the motor is disconnected from the power supply and disconnect the motor from the power supply.

To set up the multimeter: turn the multimeter to the resistance measurement mode and select an appropriate range.

Test the start winding: connect one test lead to one terminal of the motor and the other test lead to each of the other two terminals and observe the reading of the multimeter. If the reading is close to zero, there is continuity between the windings and the motor windings are fine.

Repeat the test: Repeat the above steps to test the continuity between each winding of the motor. If there is no continuity or an abnormal reading between any two windings, it may indicate a burned out motor winding.

Test winding insulation:

Prepare the test leads: Connect one test lead to the motor's windings and the other to the motor's metal case or ground.

To set up the multimeter: turn the multimeter to the resistance measurement mode and select the appropriate range.

Test insulation resistance: observe the reading of the multimeter. If the reading is very high (typically several megohms or higher), the motor's insulation is fine. If the reading is low or close to zero, it may indicate that the motor's insulation has burned out.

Test the motor rotor:

Prepare the test leads: Connect one test lead to the motor's rotor and the other lead to the motor's metal case or ground.

To set up the multimeter: turn the multimeter to the resistance measurement mode and select the appropriate range.

Test the rotor insulation: Observe the reading on the multimeter. If the reading is very high (typically several megohms or higher), it means that the motor's rotor insulation is fine. If the reading is low or close to zero, it may indicate that the motor's rotor insulation has burned out.

Test coil resistance:

Prepare the test leads: Connect one test lead to the coil pin of the motor and the other lead to the other coil pin of the motor.

To set up the multimeter: turn the multimeter to the resistance measurement mode and select the appropriate range.

Test coil resistance: Observe the reading on the multimeter. It should be close to the rated resistance of the coil. If the reading deviates significantly from the rated value or approaches infinity or infinity, it may indicate a burned out motor coil.

Test capacitors (if applicable):

Make sure the capacitor is present: Check if the motor has a capacitor. If there is a capacitor, it is usually marked on the motor.

Prepare the test leads: Connect one test lead to one pin of the capacitor and the other lead to the other pin of the capacitor.

To set up the multimeter: turn the multimeter to the capacitance measurement mode and select the appropriate range.

Test the capacitance value: observe the reading of the multimeter. It should be close to the rated capacitance marked on the capacitor. If the reading deviates significantly from the rated capacitance or approaches infinity or infinity, it may indicate a burned out capacitor.

The above are the general steps to use a multimeter to detect whether the motor is burnt out. Please note that in actual operation, follow safe operating procedures, and make sure that for a specific model and type of motor, refer to the technical manual of the motor or contact a professional for accurate testing guidance and advice. Also, if you are new to motor repair and troubleshooting, it is best to seek professional help and advice to ensure proper diagnosis and repair.

XINDA

XINDA