Introduction to the basic knowledge of low-voltage motors

Introduction to the basic knowledge of the motor:

Small three-phase asynchronous motors, usually including H80-315MM motors, have large output and wide application. In the total load of the power grid, its electricity consumption is about 40%. The JO2 series motors were popular in the early 1960s. The power level and installation size of this series of motors are different from the general standards in the international market. In addition, the starting torque of this motor is low and the noise control index is lacking. Therefore, the motors currently used in our country For Y series motors.

The motor is durable, safe and reliable, so it is used more and more widely. However, the annual damage rate of motors used by some users is as high as 5%. The reason is mostly improper selection, improper use, and poor protection. Therefore, the main purpose of this lecture is to find out the quality problems in the use of the motor and solve them properly.

System of small asynchronous motor:

Small asynchronous motors can be divided into: basic series, derivative series and special series.

Basic series ---- It is a general-purpose motor with a wide range of applications and large production capacity, such as Y series (IP44) small three-phase asynchronous motors.

Derived series--According to different usage requirements, some changes have been made on the basis of the basic series, and the other parts have high versatility and a certain degree of unity with the basic series. Derived series include electrical derivatives (such as high-efficiency motors, YX series), structural derivatives (such as wound rotor motors YR series), special environment derivatives (flameproof motors, YB series), etc.

Special series -----different from general purpose, series with special requirements and protection conditions, such as YZ, YZR asynchronous motors for metallurgy and hoisting.

Motor is a general term for motors and generators. It is usually divided into two categories: DC motors and AC motors. AC motors are divided into two types: asynchronous motors and synchronous motors.

Here is an introduction to synchronous motors , asynchronous motors , motor product model compilation methods , working system ( S type), protection type: IPXX, motor installation structure type IM XX, insulation level, asynchronous motor rated data, main technical indicators of asynchronous motors, motor selection type points.

1. Synchronous motor:

An AC motor in which the rotor speed is the same as that of the rotating magnetic field, and it is reversible. It can be used as a generator, a motor, or a compensator.

2. Asynchronous motor:

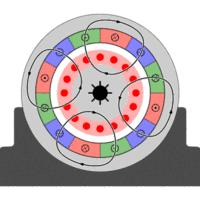

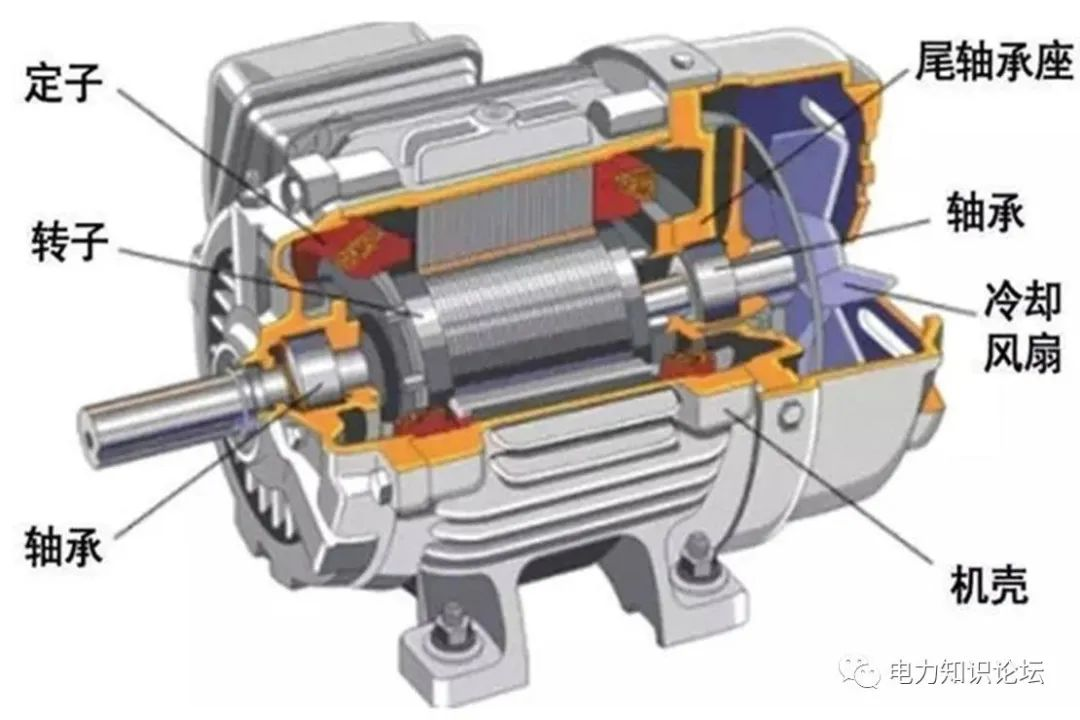

Asynchronous motor is a kind of machinery based on the interdependence and interaction of electricity and magnetism to achieve the purpose of energy conversion. Its stator and rotor are independent of each other in the circuit, but they are connected with each other through electromagnetic induction. The speed of the rotor is always lower than the speed of the rotating magnetic field, that is, there is a slip, so it is called an asynchronous motor.

Working principle: When the stator of the motor is fed with three-phase alternating current, a rotating magnetic field can be generated. Assuming that the rotating magnetic field rotates clockwise, the static cage rotor cuts the magnetic field lines to generate an induced current, and the current-carrying conductor is stressed in the magnetic field, and the torque and the magnetic field The direction of rotation is the same, so the rotor rotates along the direction of the rotating magnetic field.

3. Motor product model preparation method:

The product model consists of four parts: product code, specification code, special environment code and supplementary code.

Example:

The main product codes of low-voltage motors (1140V and below) are: Y, YDDC, YA, YB2, YXn, YAXn, YBXn, YW, YBF, YBK2, YBS, YBJ, YBI, YBSP, YZ, YZR, etc.;

The main product codes of high-voltage motors (3000V and above) are: Y, YKK, YKS, Y2, YA, YB, YB2, YAKK, YAKS, YBF, YR, YRKK, YRKS, TAW, YFKS, QFW, etc.

Commonly used special environment codes are: W (outdoor type), WF1 (outdoor medium corrosion resistance type), WF2 (outdoor strong corrosion resistance type), F1 (indoor medium corrosion resistance type), F2 (indoor strong corrosion resistance type), TH (humid tropical type), WTH (outdoor humid tropical type), TA (dry tropical type), T (dry, wet heat combined type), H (boat or sea use), G (plateau use).

4. Working system ( S category):

S1—continuous duty system, S2—short-time duty system, S3—intermittent cycle duty system, S4—intermittent duty system including starting, S5—intermittent duty system including electric braking, S6—continuous cycle duty system , S7—continuous periodic duty system including electric braking, S8—continuous periodic duty system including variable speed load, S9—non-periodical change duty system of load and speed.

5. Protection type:

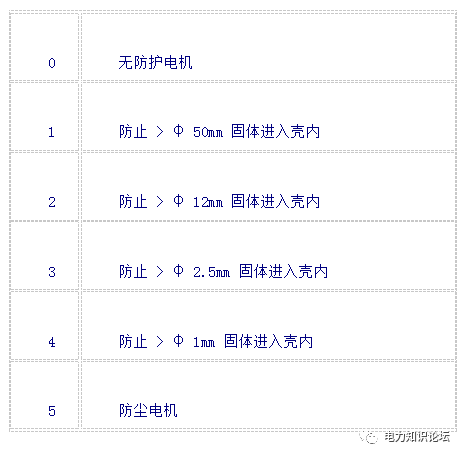

The first digit of IPXX means: prevent the human body from touching or approaching the live parts and rotating parts in the shell, and prevent solid foreign objects from entering the motor.

The second digit indicates: Protection against harmful effects due to water ingress into the motor. See the table below for the meaning of the first digit and the second digit; the first digit represents the meaning of the number:

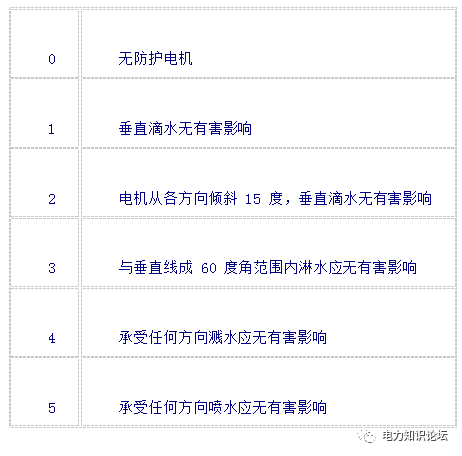

The second digit indicates: Protection against harmful effects due to water ingress into the motor. See the table below for the meaning; the second digit represents the meaning of the number:

6. Motor installation structure type:

IM XX: Common installation type code: Horizontal installation - IMB3, IMB5, IMB35 Vertical installation with shaft extension down - IMV1, IMV15, IMV5 Vertical installation with shaft extension up - IMV3, IMV36, IMV6

7. Insulation level:

The motor insulation structure refers to the structural type of the motor insulation part made of different insulating materials, different combinations and different manufacturing processes.

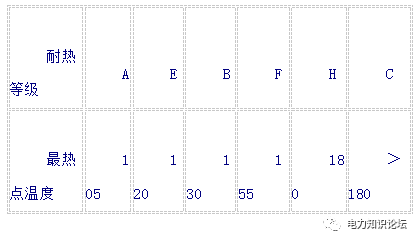

The motor insulation heat resistance grade and temperature limit are shown in the following table: Motor insulation heat resistance grade and temperature limit:

8. Rated data of asynchronous motor:

Number of phases Rated frequency (Hz) Rated power kW Rated voltage V Rated current A Rated power factor Rated speed r/min

9. Main technical indicators of asynchronous motor:

Efficiency η: The ratio of the output mechanical power of the motor to the input electrical power, usually expressed as a percentage.

Power factor COSφ: The ratio of the motor input effective power to the apparent power.

Stalled rotor current IA: The effective value of the steady-state current input from the power supply circuit when the motor is at rated voltage, rated frequency and rotor blocked.

Stall torque TK: The minimum measured value of the torque produced by the motor at rated voltage, rated frequency and when the rotor is blocked.

Maximum torque T MAX: The maximum torque produced by the motor at rated voltage, rated frequency and operating temperature without a sudden drop in speed.

Noise: A-weighted sound power level dB(A) maximum value when the motor is running in a steady state with no load.

Vibration: The effective value of the vibration velocity (mm/s) when the motor is running in a steady state with no load.

10. Key points for motor selection :

Load type Mechanical torque—torque characteristics Mechanical duty type Mechanical starting frequency Load torque inertia Whether speed regulation is required Mechanical starting and braking methods Whether mechanical rotation is required Place where the motor is used

The torque formula of a three-phase asynchronous motor is:

XINDA

XINDA