How is the motor housing packaging technology improved?

Date:2023-05-12 Author:Shandong Xinda Motor Co., Ltd.

In the manufacturing process of the motor, the packaging of the motor shell is a very important link. It can not only protect the internal components of the motor, but also improve the performance and service life of the motor. Therefore, the research on the packaging process of the motor shell is of great significance to the development of the motor manufacturing industry. At present, the research on the packaging process of the motor shell at home and abroad has made some progress.

Researchers at home and abroad have gradually accumulated some experience and knowledge about motor housing packaging through experimental research and theoretical discussions on the motor housing packaging process, which provides a useful reference for the development of the motor manufacturing industry.

However, there are still some problems and deficiencies in the research on the packaging process of the motor shell, for example, the process flow is not perfect, the technology is difficult, and the production efficiency is low.

1. The concept and function of motor housing packaging

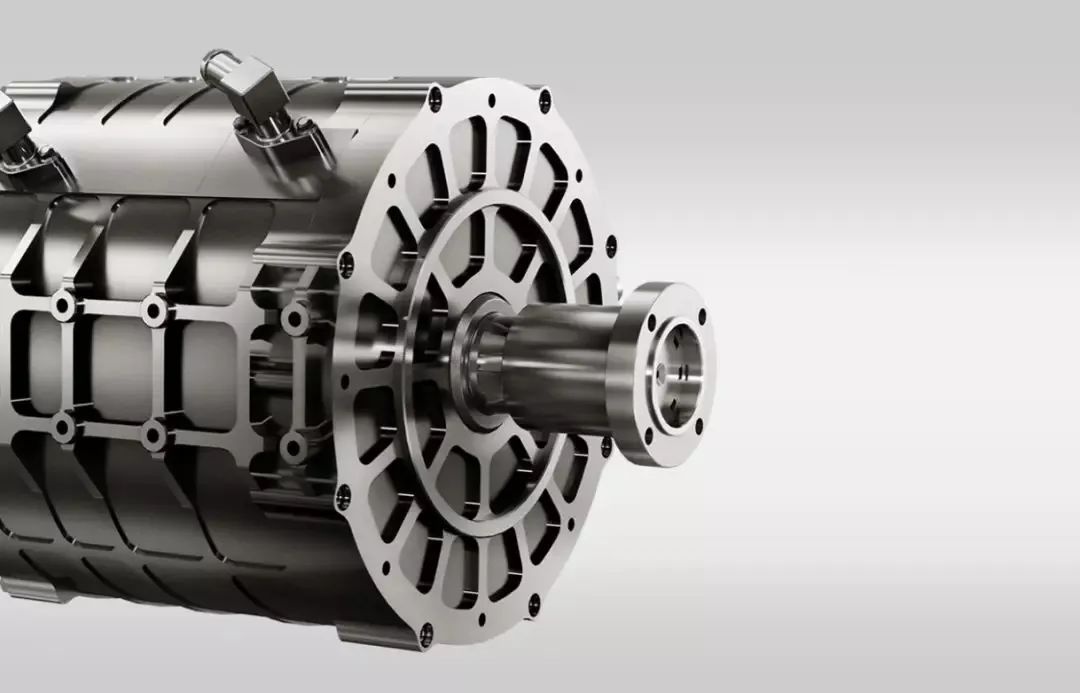

Motor housing packaging refers to the process of assembling the electrical components, electronic components and mechanical components inside the motor, and then packaging them with a housing.

Its main function is to protect the internal components of the motor, prevent dust, moisture, electromagnetic interference and other external factors from damaging and affecting the motor, and at the same time improve the heat dissipation performance and protection level of the motor to ensure the safety and stability of the motor.

The design and manufacture of motor housing packaging requires consideration of various factors, such as the rationality of the mechanical structure, the reliability of the packaging material, the requirements for sealing and protection levels, and electromagnetic compatibility.

Therefore, the research and development of the motor housing packaging process involves knowledge and technology in many fields, and requires in-depth research and exploration in materials, processes, and assembly.

2. Key technology and process of motor shell packaging process

2.1 Material

selection is a very critical step in the motor shell packaging process.

Packaging materials need to have good mechanical properties, corrosion resistance, heat insulation, water resistance, corrosion resistance, and electromagnetic compatibility.

Common packaging materials include metal, plastic, glass, and the like.

Among them, metal materials have good heat dissipation performance and mechanical strength, but their manufacture is difficult and require multiple processing and surface treatment to meet the requirements; plastic materials have a simple manufacturing process and can meet various requirements, but their mechanical strength is poor , easy to age; glass material has excellent heat insulation performance and transparency, but the manufacturing process is difficult and the cost is high.

When selecting materials, it is necessary to comprehensively consider various factors according to the actual situation, and select the appropriate material for packaging.

2.2 Design

The design of the motor shell package needs to take into account many factors, including the rationality of the mechanical structure, the reliability of the package material, the requirements of sealing and protection level, electromagnetic compatibility and so on.

At the same time, it is necessary to carry out corresponding optimization design according to the actual situation of the motor and the use environment, such as considering the heat dissipation performance of the motor, noise reduction treatment, and easy maintenance.

In the design process, it is necessary to use CAD, CAM and other software for modeling and analysis, for simulation verification and design optimization, to ensure the feasibility and reliability of the design scheme.

2.3 Manufacturing

Manufacturing is an integral step in the motor housing packaging process.

According to the design requirements, corresponding manufacturing processes are required, such as injection molding, die-casting, deep drawing, sheet metal processing, etc.

The manufacturing process needs to take into account the characteristics of the material and the difficulty of the process, and adopt an appropriate process to ensure the quality and performance of the product.

2.4 Surface treatment

Surface treatment is an important part of the motor casing packaging process.

Through surface treatment, the corrosion resistance and surface quality of materials can be improved, and the aesthetics and service life of products can be enhanced.

Common surface treatment methods include electroplating, spraying, anodizing, etc.

Different surface treatment methods are suitable for different materials and requirements, and the appropriate surface treatment method needs to be selected according to the actual situation.

2.5 Assembly

Assembly is the last step in the motor housing packaging process.

During the assembly process, it is necessary to carry out corresponding assembly and connection according to the design requirements to ensure the integrity and sealing of the package.

Pay attention to details during assembly, such as the tightening force of screws, the correct installation of gaskets, etc., to ensure the quality and performance of the package.

3. Application fields of motor housing packaging technology

Motor housing packaging technology is widely used in various mechanical equipment, such as electric tools, household appliances, automobiles, aerospace, robots, etc.

Among them, automotive and aerospace are one of the main application fields of motor housing packaging technology.

In the automotive field, the motor casing packaging process is mainly used in the packaging of automotive electric motors and motors.

The packaged motor can improve the power performance and energy-saving performance of the car, and can also improve the reliability and service life of the motor.

In the aerospace field, the motor casing packaging process is mainly used in the motor packaging of aero-engines and spacecraft.

Encapsulated electric motors can improve the reliability and safety of aero-engines and spacecraft, ensuring their normal operation and mission completion.

4. Conclusion

The packaging process of the motor shell is a very important part in the field of motor manufacturing.

Through key technologies and processes such as material selection, design, manufacturing, surface treatment and assembly, it can ensure the integrity and sealing of the motor package, improve its heat dissipation performance and protection level, ensure the safety and reliability of the motor, and meet the needs of different fields. Require.

In practical applications, it is necessary to select the appropriate material and process according to the specific design requirements and process conditions, while paying attention to details to ensure the quality and performance of the package.

XINDA

XINDA