Basic knowledge for brushless motor

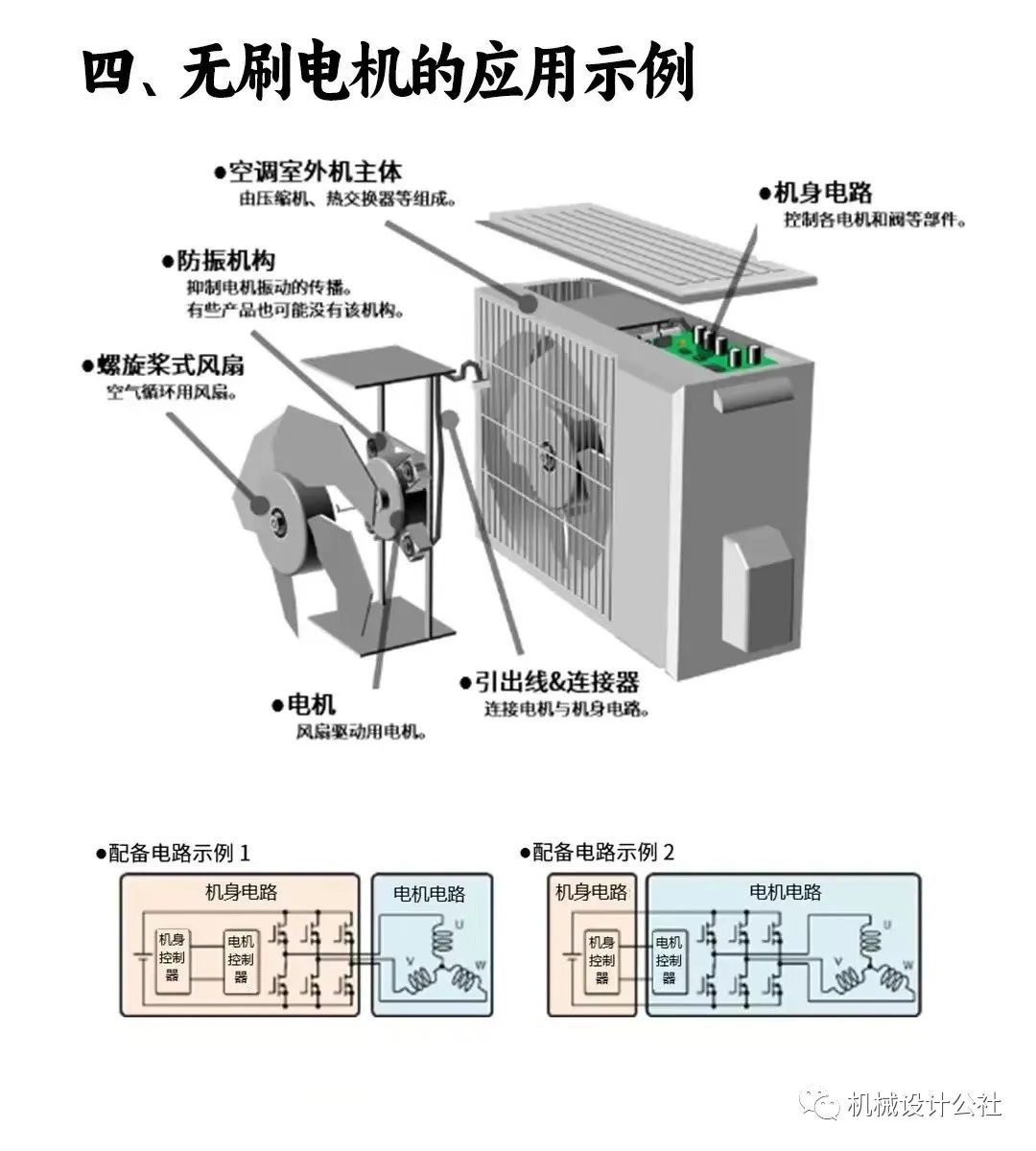

Brushless motor: This is the most commonly used motor in the mold world except for the brushed motor. The brushless DC motor does not use a mechanical brush device. It uses a square wave self-controlled permanent magnet synchronous motor, and replaces the carbon with a Hall sensor. The brush commutator uses NdFeB as the permanent magnet material of the rotor, which has great advantages in performance compared with the general traditional DC motor. It has the advantages of high efficiency, low energy consumption, low noise, super long life, high reliability, servo control, stepless frequency conversion speed regulation, etc. As for the disadvantages...it is more expensive than brushed ones, and it is not easy to maintain. It is widely used in model aircraft , High-speed car models and ship models.

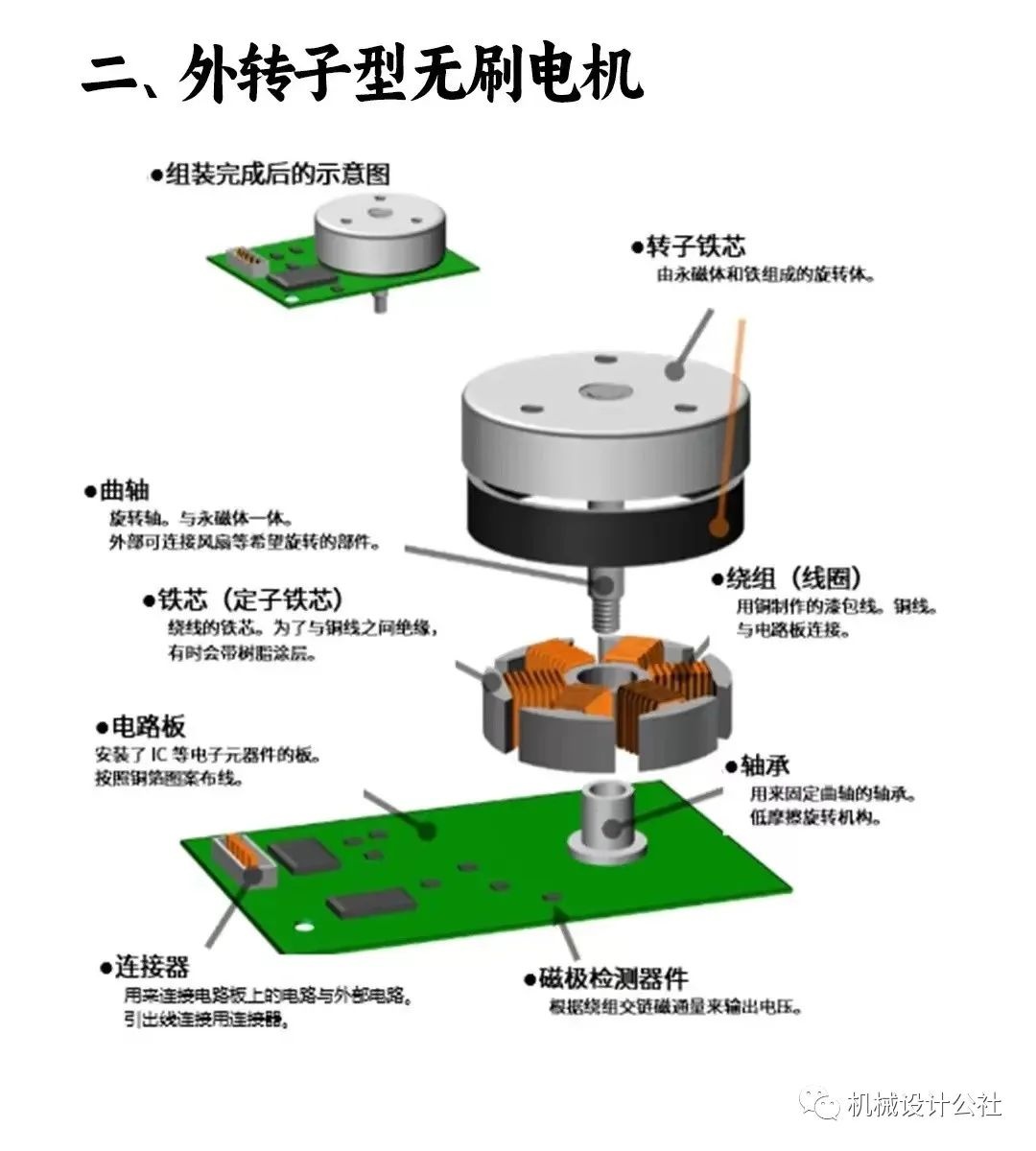

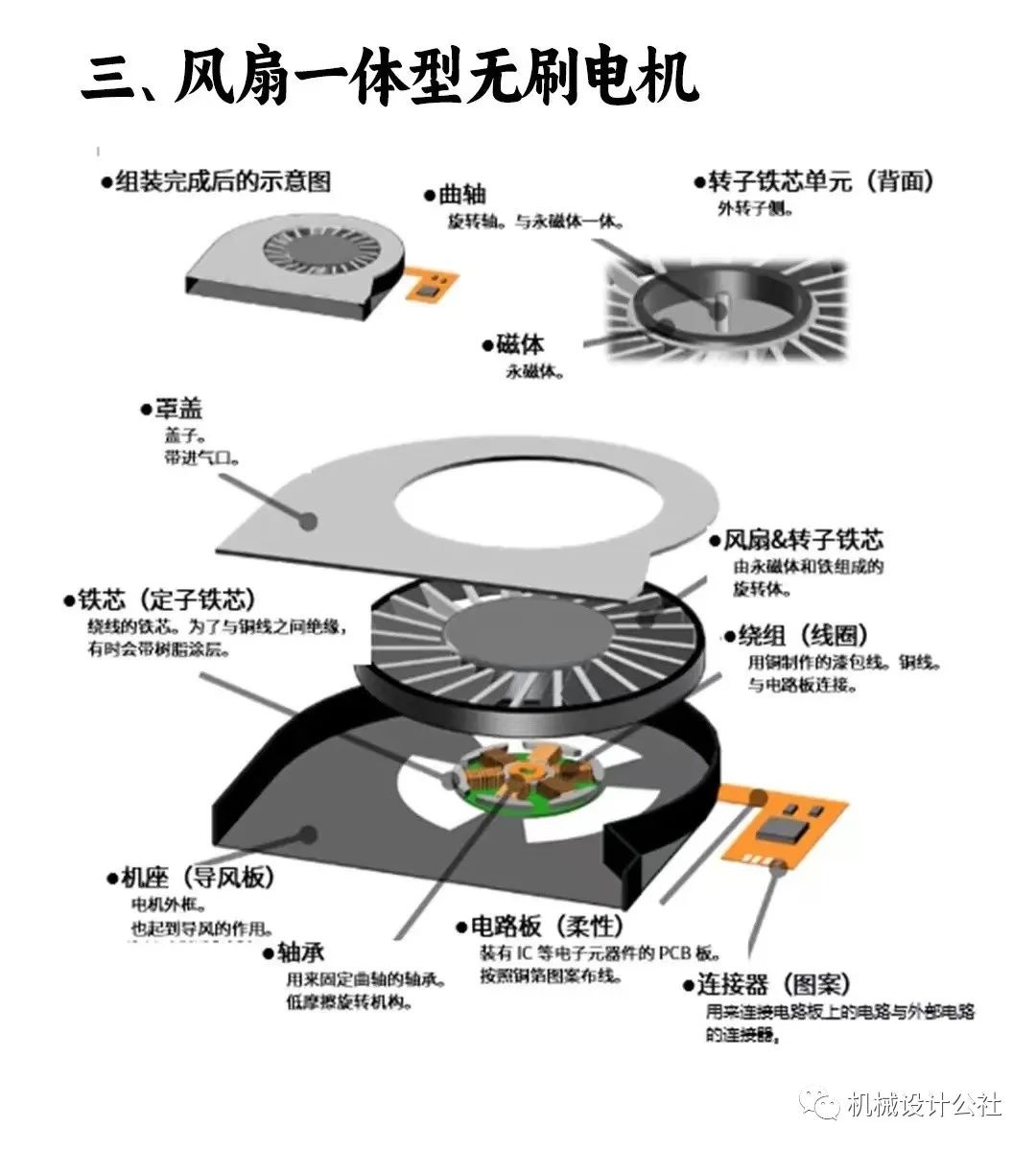

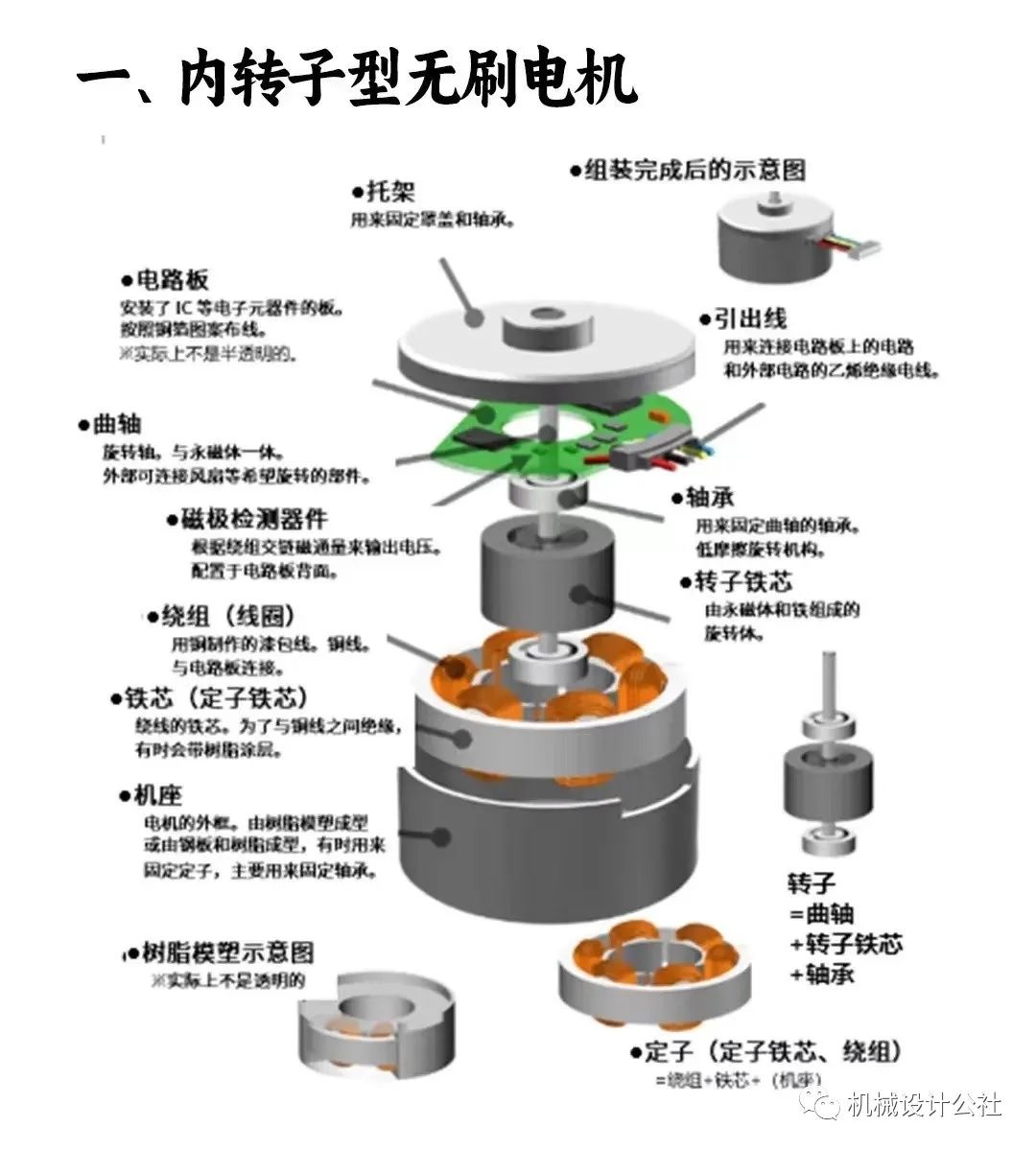

However, a single brushless motor is not a complete power system, and the brushless motor must be controlled by a brushless controller, that is, an ESC, to achieve continuous operation. Ordinary carbon brush motors rotate windings, while brushless motors rotate magnets whether they have an outer rotor structure or an inner rotor structure. So any motor is composed of a stator and a rotor.

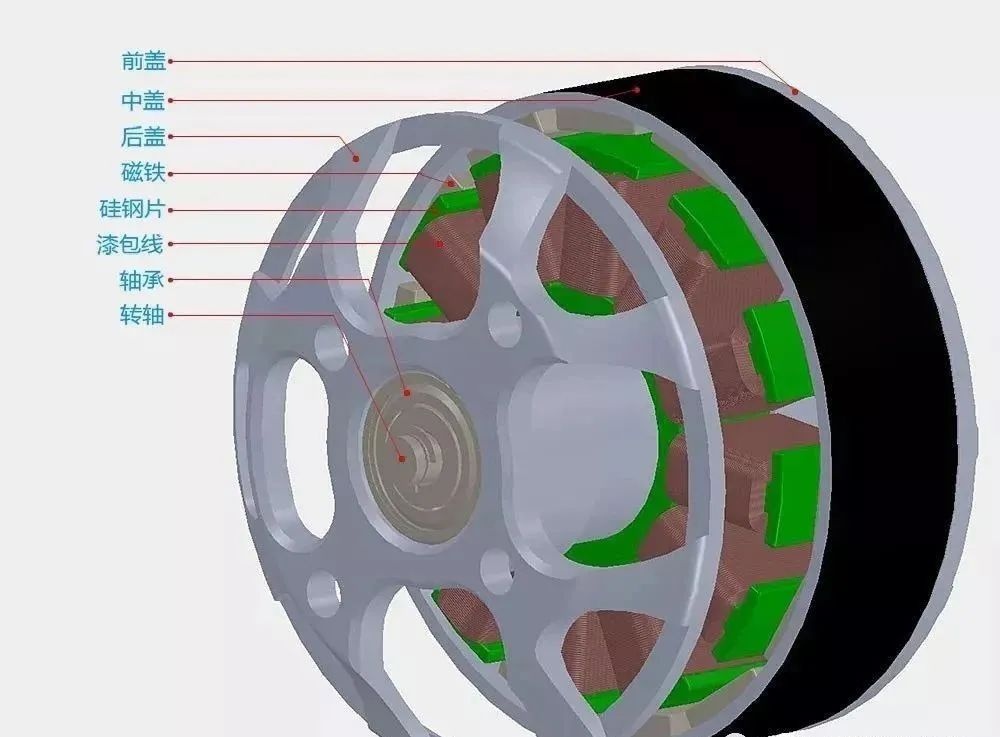

The stator of the brushless motor is the part that generates the rotating magnetic field, which can support the rotor to rotate. It is mainly composed of silicon steel sheets, enameled wires, bearings, and supports; the rotor is made of NdFeB magnets, which rotate under the action of the stator's rotating magnetic field. The components are mainly composed of a rotating shaft, a magnet and a support. In addition, the number of pole pairs formed by the stator and rotor also affects the speed and torque of the motor.

Brushless motor structure

The front cover, middle case, and rear cover of the brushless motor are mainly integral structural parts, which play a role in building the overall structure of the motor. However, the shell of the outer rotor brushless motor is also the magnetic path of the magnet, so the shell must be made of a magnetically conductive material. The shell of the inner rotor is only a structural part, so the material is not limited. However, the inner rotor motor has one more rotor core than the outer rotor motor, and the role of this rotor core is also to play the role of the magnetic circuit.

Magnet : It is installed on the rotor and is an important part of the brushless motor. Most of the performance parameters of the brushless motor are related to the magnet, including power, speed, torque, etc.

Silicon steel sheet : It is an important part of the slotted brushless motor. Of course, the slotless brushless motor does not have silicon steel sheet, but most of the current brushless motors have slots. Its role in the whole system is mainly to reduce the magnetic resistance and participate in the operation of the magnetic circuit.

Rotating shaft : It is the direct force-bearing part of the motor rotor. The hardness of the rotating shaft must meet the requirements of high-speed rotation of the rotor.

Bearing : It is the guarantee for the smooth operation of the motor. Bearings can be divided into sliding bearings and rolling bearings, and rolling bearings can be subdivided into ten categories such as deep groove ball bearings, needle roller bearings and angular contact bearings. At present, most brushless motors All use deep groove ball bearings.

XINDA

XINDA