Flat wire motor stator rotor technology and automation equipment

The general trend of new energy vehicle motor routes, the urgent demand for automated assembly lines

Permanent magnet synchronous motor is the main technical route of new energy vehicle drive motor. At present, the most widely used type in new energy vehicles is the permanent magnet synchronous motor, which has the advantages of high power density, low energy consumption, small size, and light weight. The permanent magnet synchronous motor structure includes a stator assembly, a rotor assembly, a machine base, an end cover and other auxiliary standard parts. The stator assembly includes a stator core, copper wire windings, lead wires and insulating materials, and is generally fixed to the motor housing. The rotor assembly includes rotor iron core, permanent magnet, rotating shaft, bearing and other components, which are connected with the output rotating shaft to drive the gear to drive the vehicle.

Structural model of flat wire motor

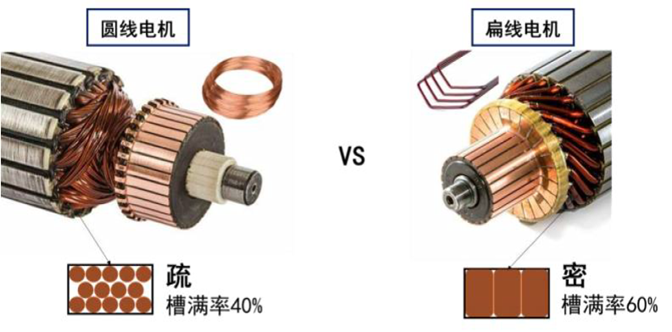

Among the permanent magnet motors, flat wire motors have obvious technical performance advantages over traditional round wire motors.

(1) Small size and high power.

(2) Reduce the copper consumption of the motor and improve the efficiency of the motor.

(3) Better temperature performance.

(4) Low mechanical noise and electromagnetic noise.

Comparison of slot fullness of round wire motors and flat wire motors

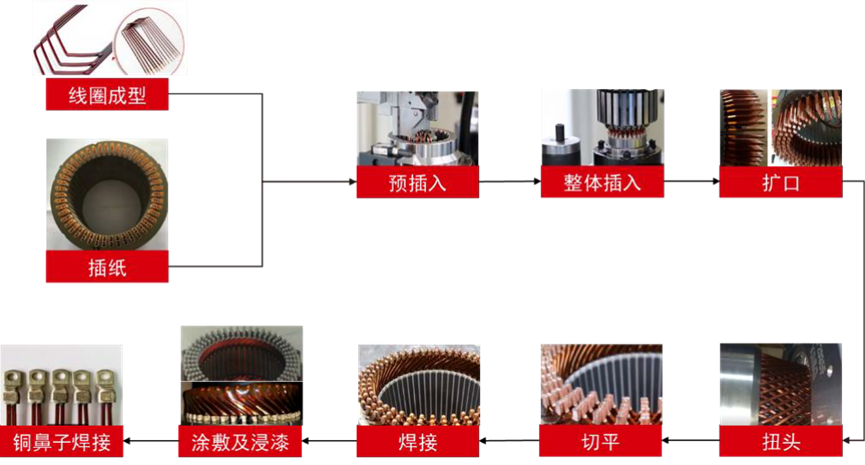

The stator assembly is the core of the design of the flat wire motor. It is difficult to produce and has the characteristics of customization. After the design is finalized, any change in the line type and size of the wire requires re-customizing expensive tooling and molds, which has low compatibility. The complete manufacturing process of flat wire motor stator components includes paper insertion, coil forming, pre-insertion, overall insertion, flaring, twisting, flattening, welding, coating and varnish dipping, and copper nose welding . The degree of dependence is higher than that of round wire motors, especially the high precision and difficulty of coil forming and welding processes, which require the use of professional high-end equipment. Overseas companies have a deep accumulation in this field, and the first-mover advantage of equipment is obvious.

Manufacturing process of flat wire motor stator assembly

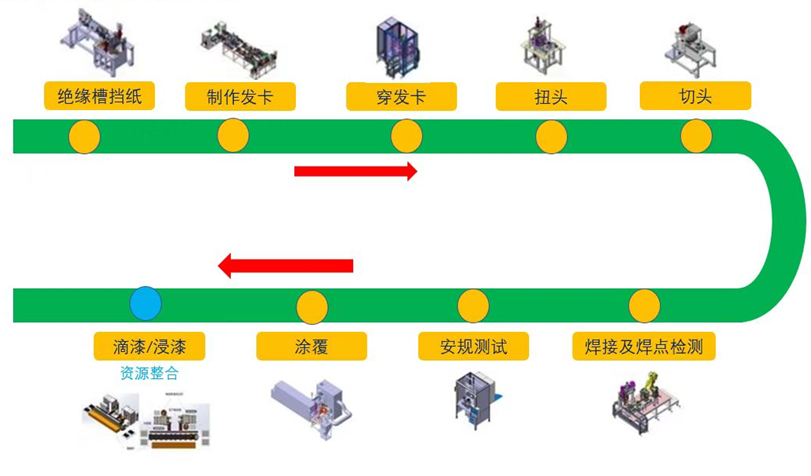

Among them, the rotor line and assembly line are relatively simple, and there are many complex processes such as non-destructive bending, insertion, twisting, laser welding, and dipping of flat wires in the stator-to-distribution line, which has great technical difficulties. At present, there is no standard flat-wire motor stator. As for the assembly process, each company is exploring process solutions. At present, there are only a few foreign equipment companies with experience in the delivery of flat-wire motor stator assembly lines, such as Comau, BorgWarner, and Felsomat . By drawing on the past technical experience in the field of fuel vehicle gearboxes, the company has successfully mastered the assembly process of flat wire motor stator wire, and has the technical ability to provide overall solutions for the three major process links of flat wire motor stator, rotor and assembly. At present , there are only a few companies in China that have the capacity to undertake flat-wire motor stator assembly lines .

Main process flow of flat wire motor stator production line

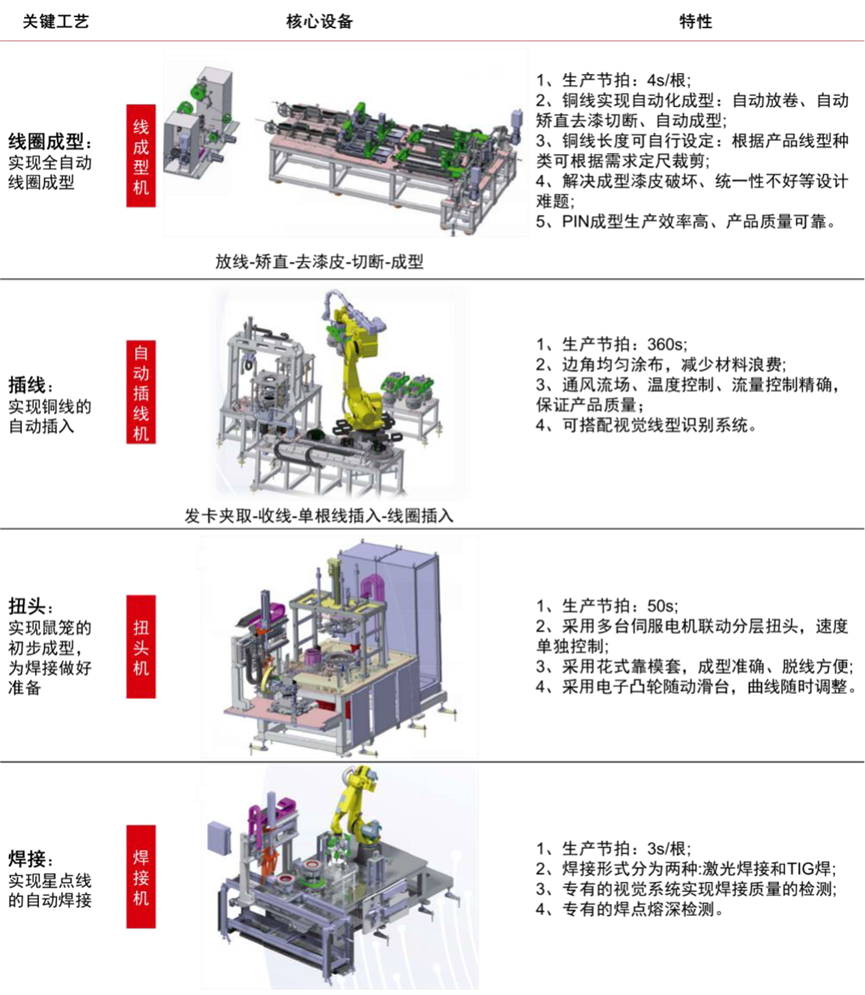

Key technology and core equipment of flat wire motor stator production line

For the key processes in the flat wire motor stator production line, including coil forming, wire insertion, twisting and welding, which are difficult and highly dependent on automation, the company has equipped with wire forming machines, automatic wire insertion machines, twisting machines and welding machines. The corresponding average production beats are 4/360/50/3 s respectively , realizing highly automated operation of the stator production line.

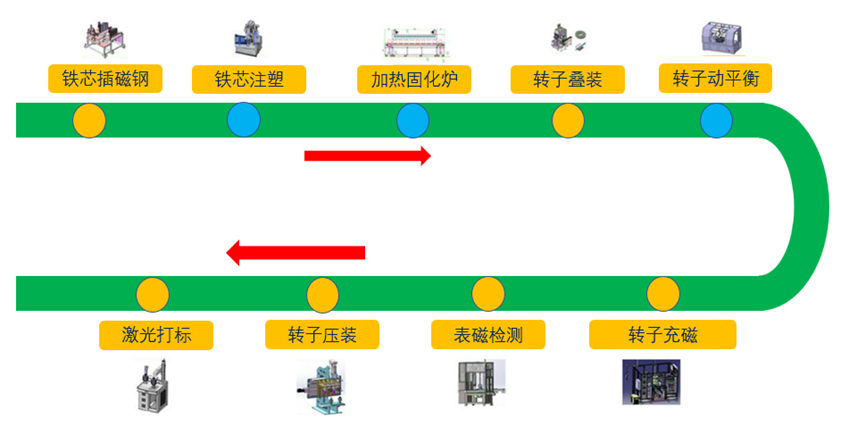

Flat wire motor rotor production line

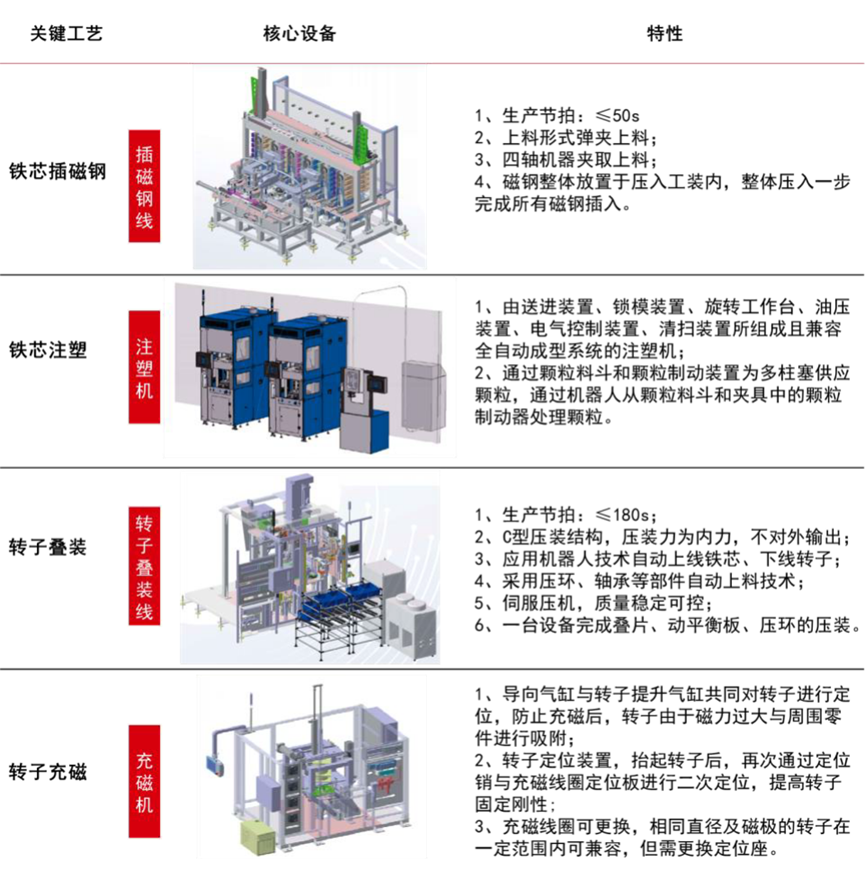

The process flow of the rotor production line is: iron core inserting magnetic steel-iron core injection molding-heating curing-rotor stacking-rotor dynamic balancing-rotor magnetization-surface magnetic detection-rotor press-fitting-laser marking. The entire production line has complicated procedures and high automation requirements, and the key processes include: iron core inserting magnetic steel, iron core injection molding, rotor stacking and rotor magnetization. The company takes full advantage of its technology and has mastered the mature flat wire motor rotor production line and assembly line.

Key technology and core equipment of flat wire motor rotor production line

Source: Forcen Institute

XINDA

XINDA