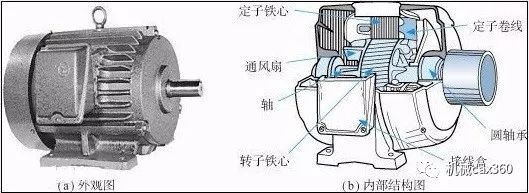

![]() Asynchronous motors are also called "induction motors", that is, the rotor is placed in a rotating magnetic field, and under the action of the rotating magnetic field, a rotational torque is obtained, so the rotor rotates.

Asynchronous motors are also called "induction motors", that is, the rotor is placed in a rotating magnetic field, and under the action of the rotating magnetic field, a rotational torque is obtained, so the rotor rotates.

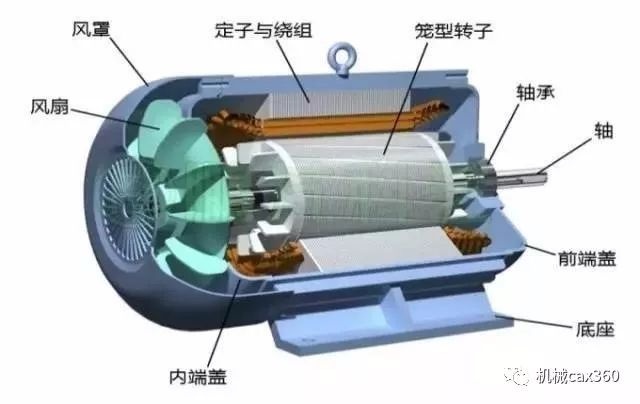

The rotor is a rotatable conductor, usually in the shape of a squirrel cage. The stator is the non-rotating part of the motor whose main task is to generate a rotating magnetic field. The rotating magnetic field is not realized by mechanical means, but is passed through several pairs of electromagnets with alternating current, so that the nature of the magnetic poles changes cyclically, so it is equivalent to a rotating magnetic field.

According to the type of alternating current used, there are single-phase motors and three-phase motors. Single-phase motors are used in washing machines, electric fans, etc.; three-phase motors are used as power equipment in factories.

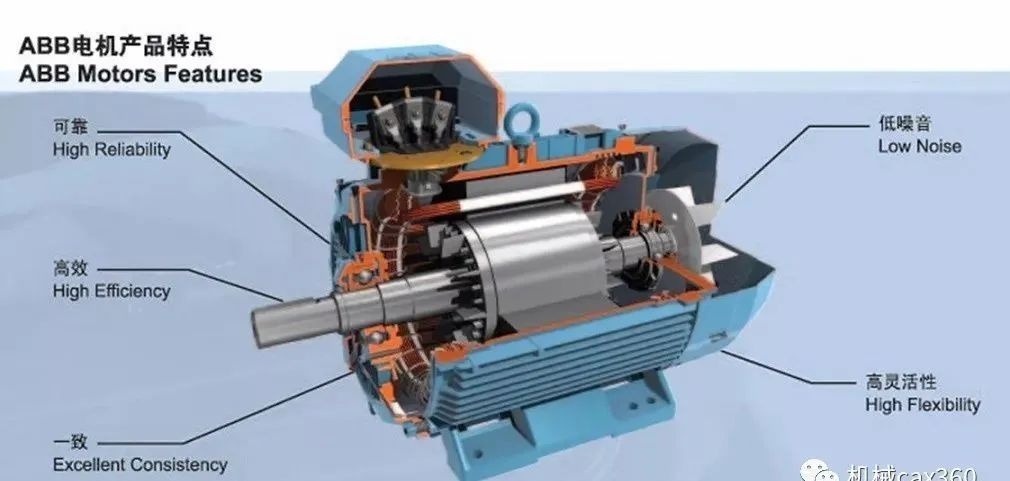

01 Working principle of asynchronous motorThrough the relative movement of the rotating magnetic field generated by the stator and the rotor winding, the rotor winding cuts the magnetic induction line to generate an induced electromotive force, thereby generating an induced current in the rotor winding. The induced current in the rotor winding interacts with the magnetic field to generate electromagnetic torque to make the rotor rotate.When the rotor speed gradually approaches the synchronous speed, the induced current gradually decreases, and the generated electromagnetic torque also decreases accordingly. When the asynchronous motor works in the motor state, the rotor speed is lower than the synchronous speed.Asynchronous motors are the most widely used in electric vehicles. Compared with DC motors, their speed adaptation range is wider, so that even if they are not equipped with a secondary differential or gearbox, they can also meet the needs of high-speed cruising of the vehicle.The asynchronous motor has the ability of variable frequency speed regulation, and its effect is equivalent to the relatively linear correspondence between the engine speed and the vehicle speed when the vehicle equipped with a continuously variable transmission is accelerated as we understand it.It is also easier to recover kinetic energy with asynchronous motors. When the vehicle is coasting or braking, the wheels anti-drag the electric motor to rotate. Under this working condition, the electric motor can generate electricity and recycle the electric energy into the battery, thereby extending the cruising range of the vehicle.The Tesla MODEL S uses an asynchronous motor, and many hybrids including the Roewe 550 Plug-in are currently using this technology. The reason why the asynchronous motor is selected is because of its strong anti-interference ability and high-speed weak magnetic field running ability. Although the power is large, the structure is simple and the work is reliable.

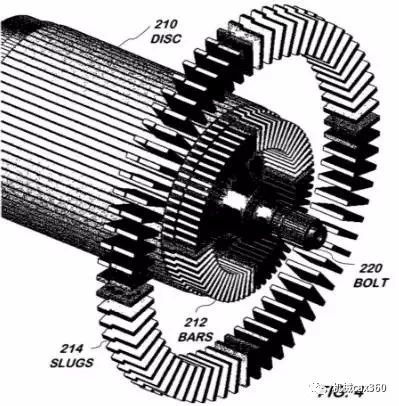

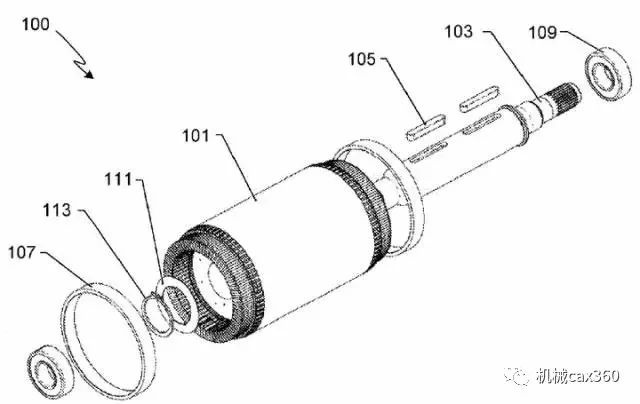

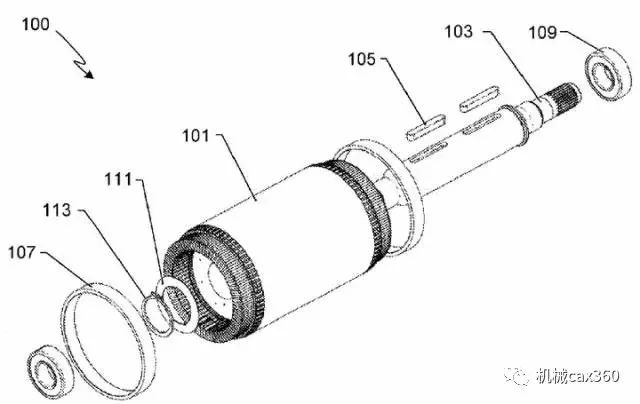

02 Tesla induction motor rotor patent

▼

The Tesla induction motor rotor patented technology is the same as the welding squirrel cage technology. The copper strips are inserted into the rotor slots. After insertion, the effect is as follows:

The next step should have been to solder the end rings, but Tesla went the other way and made a set of silver-plated copper wedges, which were inserted into the gaps at the ends of the copper bars, so that a mechanically constructed end ring Manufacture is complete.After the wedge is inserted, welding is performed between the wedge and the copper bar. This welding requirement is much lower in cost and difficulty than the induction brazing of the end ring in the welding scheme. After welding, put the confinement ring on both ends (107 parts in the picture below)This patent uses an ingenious solution to complete the manufacture of low-cost and high-efficiency copper core rotors, which can be called one of Tesla's core technologies.

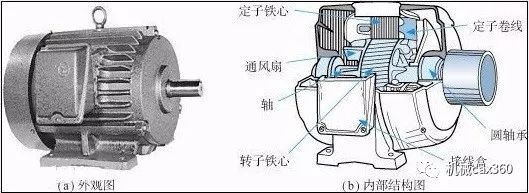

03 Induction motor diagram

▲Unidirectional induction motorHow a single-phase induction motor works. The stator usually has two windings and the rotor is cage-shaped. Most single-phase induction motors operate in one direction because they are designed to rotate in one direction.▲Unidirectional induction motor▲Unidirectional induction motor▲Three-phase induction motorThe three-phase induction motor is an AC motor in which the rotating magnetic field formed by the stator winding interacts with the magnetic field of the induced current in the rotor winding to generate electromagnetic torque to drive the rotor to rotate. It is a kind of induction motor.▲Three-phase induction motorFor most fan and pump loads that do not need speed regulation, the AC speed regulation can greatly save energy. Therefore, the research on speed regulation and energy saving of induction motors is of great significance.▲Three-phase induction motorThree-phase induction motors are mainly used in computer peripheral equipment, lathe systems, photoelectric combination devices, valve control systems, nuclear reactors, surface grinders, CNC machine tools, automatic winding machines, electronic clocks and medical equipment and other fields.

XINDA

XINDA