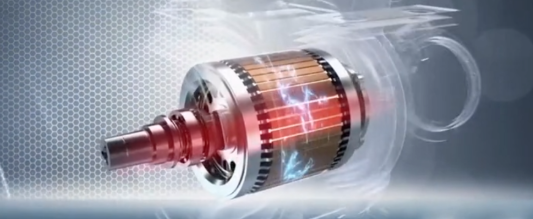

Permanent magnets are all good, but demagnetization is too distressing?

Once the permanent magnet motor loses its magnetism, basically you can only choose to replace the motor, and the maintenance cost is a lot. How to judge the loss of magnetism of the permanent magnet motor, let's look down.

1. The current of the machine is normal when it starts to run. After a period of time, the current becomes larger. After a long time, it will report that the inverter is overloaded.

First of all, it is necessary to confirm that the air compressor manufacturer’s frequency converter is correct, and then confirm whether the parameters in the frequency converter have been changed.

If there is no problem with both, you need to judge by the back electromotive force, disengage the machine head from the motor, carry out no-load identification, and run it to the rated frequency without load. At this time, the output voltage is the back electromotive force. If it is lower than the motor nameplate If the counter electromotive force is above 50V, it can be determined that the motor is demagnetized.

2. After the permanent magnet motor is demagnetized, the operating current will generally exceed the rated value by a lot

Those situations where overload is only reported at low or high speed or occasionally reported are generally not caused by demagnetization.

3. It takes a certain amount of time to demagnetize the permanent magnet motor, some months or even a year or two

If the manufacturer chooses the wrong type and causes the current overload to be reported, it does not belong to the demagnetization of the motor.

Reasons for motor demagnetization

-

The cooling fan of the motor is abnormal, resulting in high temperature of the motor

-

The motor is not equipped with a temperature protection device

-

Ambient temperature is too high

-

Motor design is unreasonable

How to prevent demagnetization of permanent magnet motor? ? ?

-

Correct selection of permanent magnet motor power

-

Demagnetization is related to the power selection of the permanent magnet motor.

Correct selection of the power of the permanent magnet motor can prevent or delay demagnetization.

The main reason for the demagnetization of the permanent magnet synchronous motor is that the temperature is too high, and overload is the main reason for the high temperature.

Therefore, a certain margin should be left when selecting the power of the permanent magnet motor. According to the actual situation of the load, generally about 20% is more appropriate.

-

Avoid heavy starting and frequent starting

The cage-type asynchronous start synchronous permanent magnet motor should try to avoid heavy load direct start or frequent start.

In the process of asynchronous starting, the starting torque is oscillating, and in the trough section of the starting torque, the stator magnetic field demagnetizes the rotor magnetic poles.

Therefore try to avoid heavy load and frequent starting of asynchronous permanent magnet synchronous motor.

XINDA

XINDA