3 nanometers for motor industry! Aion brings future technology imagination!

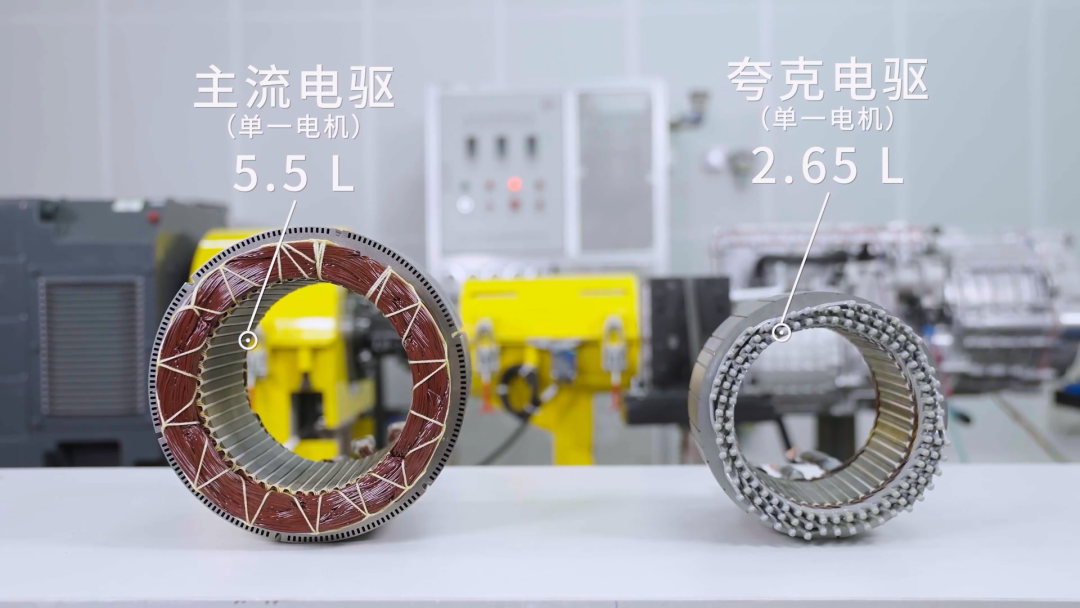

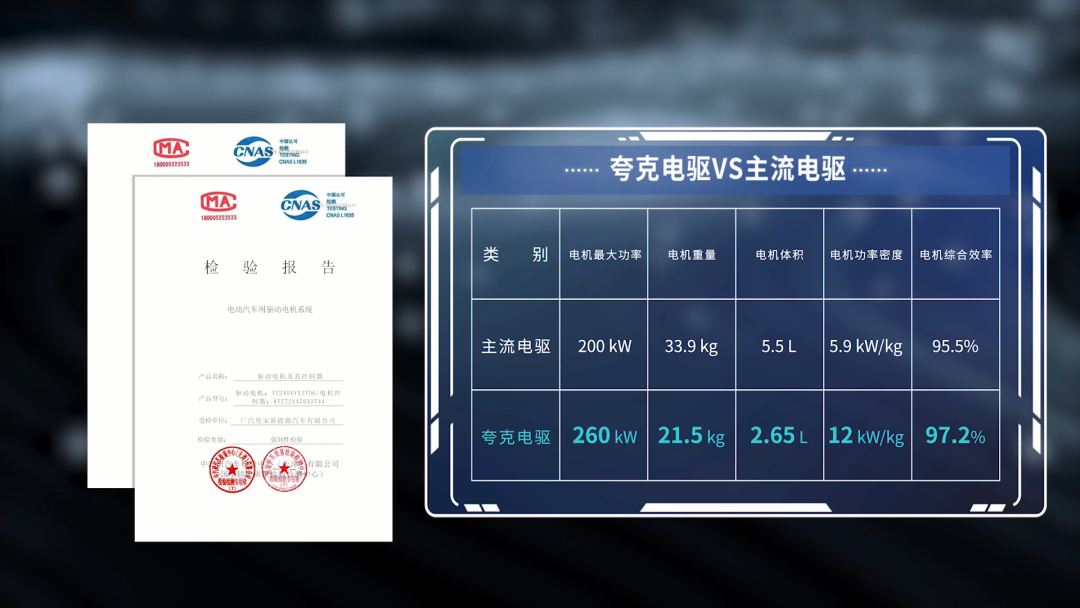

Recently, Aion released the quark electric drive technology, which increased the power density of the motor to 12kW/kg for the first time, significantly ahead of the industry mainstream 6kW/kg level. Just a palm-sized motor can burst out super power beyond the V8 engine. At the moment when motors are highly popular, the technological breakthrough of quark electric drives will undoubtedly have a profound and positive impact on people's lifestyles.

In fact, two days ago, Tesla also announced the relevant content of the new electric drive technology in "Chapter Three", the main optimization of which is to optimize costs by reducing the use of rare earth metals. In contrast, Aian's quark electric drive is constantly challenging the limit of power density, enriching people's imagination of future technological life.

Attacking the "3 nanometers" of the electric drive industry

From the perspective of technological development, ultra-integration and high efficiency are the general trend, but every step of improvement is extremely difficult.

As early as 1900 at the Paris World Expo, the founder of Porsche, Ferdinand Porsche, had demonstrated a pure electric vehicle System Lohner-Porsche equipped with hub motors. However, this disruptive technology has been silent for a hundred years and has not seen a wide range of application scenarios. ; Before Tesla launched the Model S, the Roadster considered a two-speed single-motor power solution at the beginning of its development, but limited by the gearbox technology, it could only choose a more powerful and bulkier motor solution.

It can be seen that it is not easy to increase the power density of the motor. It is necessary to consider achieving greater power output while maintaining the same volume, but also to avoid high power output loss. Constrained by these two major problems, in the past 10 years, the industry average level of motor power density of electric vehicles has increased from 2kW/kg to 6kW/kg. The breakthrough in motor power density is no less than the ultimate pursuit of chips from '28 nanometers' to '3 nanometers'.

"Slap motor" creates a new height of power density

The quark electric drive released by Aian this time broke through the contradiction of "big power and small volume" for the first time. According to Yu Hao, R&D Director of GAC Aian Electric Drive, the quark electric drive focuses on the two core points of "high power density and low heat loss", and uses disruptive technology to double the power density of the motor. The power density of 12kW/kg, compared with The industry has increased by 100%, and the output loss of the motor has been reduced by 50%.

"Nanocrystalline-Amorphous" Super Efficiency Motor

Since the development of permanent magnet synchronous motor technology, the core loss of the motor is the main factor affecting the efficiency of the motor. Aian has innovated and developed the basic raw material electromagnetic principle, and designed the "nanocrystalline-amorphous" alloy material. The single-layer steel plate thickness of this material is only 1/4 of the thickness of standard A4 paper, and the cooling rate is as high as 1 million ℃/s, which is 1000 times faster than iron-based silicon steel materials. Thanks to these characteristics, Aion can reduce the core loss of the motor by 50%, the efficiency of the motor under working conditions is 97.2%, and the maximum efficiency of the motor is 98.5%.

The industry's first X-PIN flat wire winding

Aian owns the X-PIN flat wire winding stator configuration design and the carbon fiber high-speed rotor design with its own patented technology. This is the key to the miniaturization and weight reduction of electric drives. The voltage resistance of the motor is improved by the composite paint film copper wire with a voltage exceeding 2100V, the low-circulation flat copper wire winding reduces the heat generation of the winding, the precise application of rare earth magnets improves the efficiency of the motor, and the high-speed, high-torsion carbon fiber rotor and low magnetic saturation magnetic circuit design improve power and torque output. , In the case of reducing the volume of the motor by 25%, the power is increased by more than 30%, laying the supercar gene for Haobo.

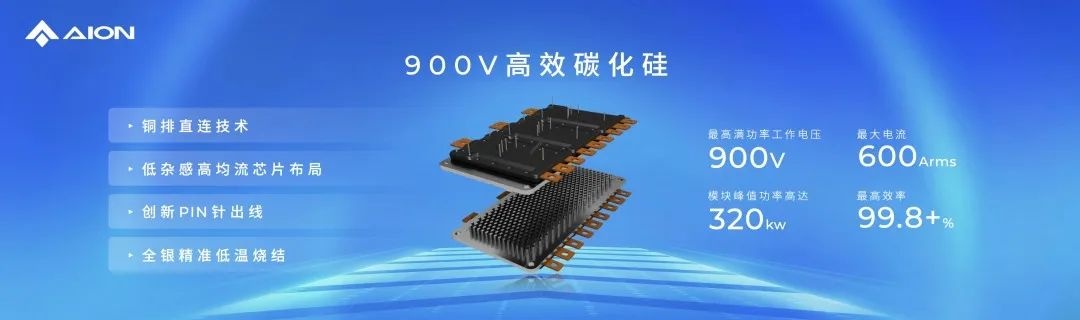

900V SiC Power Module

Quark electric drive technology adopts a 900V high-voltage platform system, replaces the traditional packaging process with a unique trench gate structure, and innovates in many aspects such as chip layout, chip current sharing, reducing chip switching delay, and all-silver precise low-temperature sintering process , to achieve a 50% reduction in SiC module circuit noise, a 25% reduction in thermal resistance, a 16% increase in the maximum operating junction temperature of the chip, and a 10% increase in chip flow capacity.

The design of high voltage and high current enables the peak power of silicon carbide modules to reach 320kw, ranking first in the industry.

Let future technology shine into reality

"Quark is the smallest particle discovered in human physics so far, and it is also the basic unit of matter. It not only represents Ian's pursuit of the ultimate power density of electric drive, but also presents the beautiful vision of quark electric drive to drive all things." Deputy Ian General Manager Zhang Xiong's speech shows the brand's determination and original intention to pursue technology. The breakthrough and innovation of technology is no longer limited to the single field of "car".

The release of the quark electric drive is undoubtedly stronger performance and larger space for new energy vehicles, but its impact is far less than that.

In the sci-fi movie "Alien", Ellen Ripley is invincible when fighting against the alien queen with a set of mechanical armor.

When the "Iron Man Suit" came into reality from science fiction, due to the need for multiple motors to control, only when the size of the motor is miniaturized and the power is huge can the giant be lifted without affecting the movement of the hip joint. The quark electric drive with small size and high power will lead to technological innovation and even mass production in the fields of mechanical exoskeleton, medical technology, aviation, aerospace and other forward-looking technologies.

Taking the Mars rover as an example, power is needed when exploring outer space, but limited by the environment and drive system (heat loss, self-weight, etc.), the current technical level may only last for one hour, but with the advancement of electric drive technology, the volume Shrinking and increasing power density, it may be possible to go out and explore for a day, a week, or even longer in the future. Another example is in the field of medical science and technology, quark electric drive can be used to make powered prosthetics, so that disabled people can also have the mobility of normal people; the field of drones can also use quark electric drive technology, which greatly improves its carrying capacity and battery life. Perhaps In the not-too-distant future, the unmanned express delivery business is no longer a distant fantasy...

Just like the steam engine drove the first industrial revolution, the motor will be the key to open the door to smart technology in the future world. Quark electric drive allows people to have a broader imagination space for future technological life.

Open up the growth space of Aian

At present, the wave of intelligent electrification is sweeping, and a stable ecological niche has not yet been formed. "Luxury" is no longer exclusive to BBA, and "technology" is no longer the only traditional luxury brand. Tesla, Wei Xiaoli New car companies such as , Aion, etc. are struggling to compete for the right to speak in the era of smart electric vehicles. The breakthrough of key technologies and the implementation of mass production are the core competitive advantages of vehicle manufacturers.

Up to now, Aian has formed a power technology full-stack self-research team with more than 1,000 people, invested a total of more than 10 billion special funds, and built more than 800 core fields covering software algorithms, control strategies, hardware development, and simulation design. patented technology.

A series of Hyper Tec, such as Quark electric drive, a new generation of high-end pure electric exclusive platform AEP 3.0, and the "all-weather smart driving safety" Protoss architecture, continue to shape the DNA of Aion Technology, and the million-dollar supercar Hyper SSR and benchmark Tesla Model 3 The Hyper GT has been unveiled. While technology iterations and high-end branding continue, Aian is stepping up the pace of mass production of technology.

At the end of last year, Ruipai Power Technology Co., Ltd. started construction, focusing on the research and development and industrialization of power technology, and built a technical moat integrating research, production and sales. Because of Pai Battery Company and Energy Technology Company, further strengthen competitiveness, better cost control and realize the independence of the industrial chain.

With the advantage of sales scale and the blessing of full-stack self-research, the rapid rise of Aian has made the outside world see the potential of a new generation of new forces. The capital market is very confident in Aian. A few days ago, Aian introduced a total of 53 strategic investors in the A round of financing, with a total financing of 18.294 billion yuan, released 17.72% of the shares, and a valuation of over 100 billion, creating the current new energy vehicle industry. The largest single private equity financing is also the highest valuation of an unlisted new energy car company so far.

XINDA

XINDA