Chinese domestic TOP20 servo motor suppliers

The high-performance servo system can provide flexible, convenient, accurate and fast drive for electromechanical equipment, and optimize the control of production links such as industrial product inspection, scheduling and management. Next, the editor will take stock of well-known manufacturers in the domestic servo motor industry!

|

enterprise |

business field |

|

Inovance Technology |

General Servo Service |

|

Collier |

Mainly used in robotics, industrial automation, artificial intelligence and New energy vehicles and other fields |

|

Jiangsu Leili |

Mainly used in medical equipment, automobile field and other fields |

|

Star Technology |

Mainly used in military fields, industrial fields and new energy fields |

|

Haozhi Electromechanical |

Master high-end servo drive, servo motor and CNC system technology, And reserves the application capabilities in the fields of hydrogen energy and environmental protection |

|

Sine Electric |

High-precision servo drive products |

|

VEICHI Electric |

Widely used in mask machines, machine tools, food packaging machinery and other mechanical equipment. |

|

Weiguang shares |

Mainly used in textile machinery, industrial automation, robots, etc. field. |

|

Hechuan Technology |

Widely used in 3C electronics, lithium batteries, logistics and other industries |

|

Jiangte Motor |

Mainly used in new energy, military industry and industrial construction |

|

Eston |

At present, all-electric servo presses and servo turret punches have been developed Complete solution for automation , electro-hydraulic hybrid servo system, Motion control system, DC servo drive, robot Dedicated Servo System |

|

Blue Ocean Huateng |

The key development areas are new energy electric vehicles and industrial automation field |

|

Kinco shares |

Developed several series of low-voltage servo systems for mobile robots, Logistics sorting equipment high-voltage servo system, medical European standard servo system etc. |

|

Huazhong CNC |

For popular CNC lathes, CNC milling machines, new energy vehicles Car provides servo products |

|

INVT |

The products are mainly used in new energy vehicles, robots and other fields. |

|

Raytheon Smart |

Mainly used in photovoltaics, lithium batteries, robots, inkjet printing, Textile and garment, packaging and other industries |

| New Times |

Mainly used in industrial robots |

| Wolong electric drive | General Servo Service |

| Aerospace appliances | Aerospace field, industrial robot |

| MOONS' | Medical equipment, electrical appliances, industrial robots |

At present, the servo products independently developed by domestic listed companies are mainly used in the fields of industrial people and new energy vehicles.

Part 1

Concept and working principle

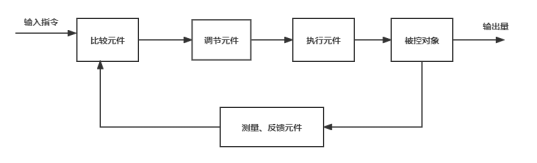

A servo system is a motion control component consisting of a servo drive and a servo motor. The servo drive refers to the power electronic device that controls the angle, speed, and torque of the servo motor, and belongs to the drive layer. Servo motor refers to the engine that controls the operation of mechanical components in the servo system. It is an auxiliary motor indirect speed change device and belongs to the executive sensing layer.

In the servo system, the servo driver sends a signal to the servo motor to drive its rotation. At the same time, the encoder feeds back the motion parameters of the servo motor to the servo driver. The servo driver then summarizes, analyzes and corrects the signal. The speed is the control quantity, which dynamically tracks the change of the target position.

Part 2

Classification and representative manufacturers

According to the size of the power, the servo system can be divided into small servo, medium servo and large servo system. According to the different implementation components, it can be divided into hydraulic servo system, electrical servo system and pneumatic servo system, and the electrical servo system can be divided into DC servo system and AC servo system.

|

product structure |

power range |

Application industry |

Representative manufacturer |

|

small servo |

<1KW |

It is mostly used in small machinery such as industrial robots, electronic manufacturing, and textile packaging equipment. |

Panasonic, Mitsubishi, Delta |

|

medium servo |

1-7.5KW |

It is mostly used in medium-sized machinery such as milling machines, injection molding machines, packaging machines, and drilling machines. |

Yaskawa |

|

large servo |

>7.5KW |

It is mostly used for large-scale CNC machine tools, all-electric injection molding machines, wind turbines and other large machinery. |

Siemens, Bosch Rexroth |

There are differences between DC servo and AC servo in principle, control mode and performance. Compared with AC servo, DC servo is widely used in AGV, medical equipment, instrumentation and other fields due to its advantages of simple structure, reliable operation, convenient maintenance, and high operating efficiency. For printing equipment, laser processing, robots, machine tool equipment, manipulators and other industrial production lines that have higher requirements for control accuracy, speed and torque.

|

the difference |

DC servo |

AC servo |

|

principle |

The rotor is also a permanent magnet, and the stator winding is powered by a servo-encoded pulse circuit. |

The three-phase coil of the stator is powered by the servo coding control circuit, the rotor is permanent magnet, and the steering, speed and rotation angle of the motor are all determined by the coding controller. |

|

control method |

Armature voltage control, field field control |

Amplitude Control, Phase Control, and Amplitude-Phase Control |

|

performance advantage |

Accurate speed control, hard torque and speed characteristics, simple control principle, good linear adjustment characteristics, fast time response, easy to use, and cheap |

The structure is simple, the cost is low, and the rotor inertia is smaller than that of the DC motor; the capacity of the AC motor is larger than that of the DC motor |

|

performance disadvantage |

The brushes and commutator are easy to wear, and sparks are generated during commutation, which limits the speed; the structure is complex, difficult to manufacture, and high in cost |

The control is more complex, the drive parameters need to be adjusted on site to determine the PID parameters, and more connections are required |

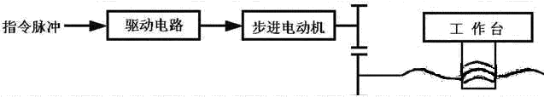

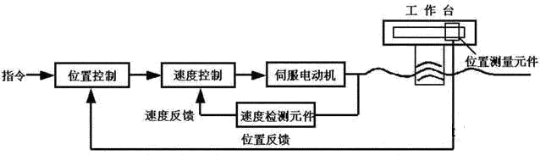

According to different control and adjustment principles, it can be divided into open-loop servo system, closed-loop servo system, and semi-closed-loop servo system. The open-loop servo system is a system without position feedback, and its driving components are mainly power stepping motors or hydraulic pulse motors. The closed-loop servo system is an error control follow-up system. The actuator cannot reflect the position of the movement, and a position detection device is required. The control structure of the closed-loop servo system is the same as that of the open-loop system.

Open loop servo system structure

Part 3

Technology Status

The servo system is an industrial automation control product. The technical difficulties mainly lie in whether it has the self-adjustment function, the response speed of the servo driver, and the electromagnetic design technology. Product with high reliability and stability.

Relying on the technology application experience accumulated in the industry for a long time, leading foreign manufacturers still have relatively high competitive advantages in terms of control performance, product reliability, software core algorithms and overall solutions. The research on servo system in our country started relatively late, and domestic manufacturers started the research and development of civilian servo system after 2000. At present, my country has completed the research and development and mass production of low-end servo systems, and high-end servo technology is still in the research and development stage.

Part 4

Policy Support

According to the "Strategic Emerging Industries Classification (2018)" issued by the National Bureau of Statistics, the industry in which the servo system is located is "manufacturing of intelligent key basic components" in the "high-end equipment manufacturing industry".

2015

The State Council issued "Made in China 2025", which included servo drives and servo motors for high-precision robots as key components for key development, and supported the development and industrial application of key components.

2019

Thirteen departments including the Ministry of Industry and Information Technology and the National Development and Reform Commission issued the "Special Action Plan for Improving Manufacturing Design Capabilities (2019-2022)", proposing key designs for strengthening the high-end equipment manufacturing industry. In the field of high-end CNC machine tools and robots, focus on breakthroughs in system development platform and servo mechanism design.

2021

The State Council issued "The 14th Five-Year Plan for National Economic and Social Development of the People's Republic of China and Outline of Long-term Goals for 2035", clearly proposing to focus on the development of distributed control systems, programmable logic controllers, data acquisition and video surveillance systems and other industries Control equipment, breakthroughs in key technologies of intelligent robots such as advanced controllers, high-precision servo drive systems, and high-performance reducers.

2022

The "Industrial Energy Efficiency Improvement Action Plan" jointly issued by six departments including the Ministry of Industry and Information Technology proposes to implement actions to improve the energy efficiency of energy-consuming systems, carry out energy-saving transformation of key energy-consuming equipment systems, and optimize operation control. Accelerate the application of technologies such as high-efficiency centrifugal fans, low-speed high-torque direct drives, high-speed direct drives, and servo drives to improve the efficiency and quality of motor systems such as fans, pumps, and compressors. The development of servo drive technology is of great significance, whether it is from the domestic substitution of technology to deal with the situation of foreign technology monopoly, or from the perspective of industrial energy efficiency improvement.

Part 5

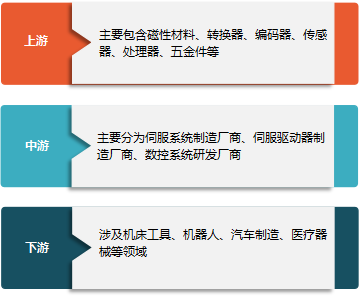

Industry chain map

As the main raw material for the production of magnetic materials - rare earth, the raw material, reserves and output rank first in the world, and will maintain a long-term loose supply in the future. The overall upstream supply is relatively loose. As an indispensable component of the servo system, encoders and sensors are supported by national policies, and key technologies have made continuous breakthroughs. However, with the rise of raw material prices, the manufacturing cost of servo enterprises has also risen.

At present, the scale of my country's servo market has exceeded 20 billion yuan, and the compound annual growth rate between 2017 and 2021 will reach 23.3%. Some organizations predict that with the advancement of industrial automation and intelligent manufacturing, the servo system market will benefit from the rapid development of industrial robots, smart cars and other industries and usher in a new round of explosive growth. The market size is expected to reach 29.5 billion yuan in 2023. Among them, the market share of servo systems for robots will increase to more than 40%, and the market size will reach 4.10 billion yuan. According to the data from Enterprise Check, there are currently more than 5,000 servo companies in my country.

Part 6

Market analysis

From the perspective of market share, my country's domestic servo market share continues to increase, mainly in the field of small servo breakthroughs, most of the market is still occupied by foreign brands. Among them, Japanese brands account for the largest proportion, mainly including Panasonic, Mitsubishi Electric, Yaskawa, Fuji, Sanyo and other old Japanese industrial automation equipment manufacturers. Secondly, European and American brands mainly occupy the medium and large servo system market, mainly including American brands such as Rockwell, Danaher, and Paguang, and German brands such as Siemens, Bosch Rexroth, Lenz, and Schneider.

|

area |

enterprise |

business |

|

Japanese brand |

Matsushita |

The small AC servo motors and drivers launched by Panasonic are very popular in the market, among which the large inertia series are suitable for CNC machine tools, and the medium inertia series are suitable for robots. |

|

Yaskawa |

The first company in Japan to produce servo motors, its products are known for their stability, speed, and high cost performance. It is the servo brand with the largest sales volume in the world and the most used industry. From general industrial machinery to semiconductor and electronic component manufacturing equipment, Yaskawa can provide the most suitable servo and controller products for various purposes. |

|

|

mitsubishi |

Mitsubishi servo amplifiers in Mitsubishi servo systems are widely used, not only for work machinery and general industrial machinery that require high-precision position control and smooth speed control, but also for speed control and tension control. |

|

|

European and American brands |

Siemens |

Siemens servo motors are rich in types and compact in structure, which can achieve excellent dynamic characteristics and operating efficiency, complete performance levels, and various installation specifications. |

|

Lenz |

The company's active product, the MCM synchronous servo motor, focuses on the robot market. It has a compact structure, a good ratio of load to motor inertia, a smooth shell, and is easy to use. It is suitable for packaging, handling and other application scenarios. |

|

|

Taiwan brand |

Delta |

The control loops of Delta's servo products all use high-speed digital signal processors (DSP), which can meet motion control requirements such as high-speed displacement and precise positioning with automatic gain adjustment, command smoothing function design, and software analysis and monitoring. |

XINDA

XINDA