The requirements for four-wheel drive have increased, learn about card-issuing asynchronous motor

Date:2023-03-08 Author:Shandong Xinda Motor Co., Ltd.

01 Stronger power and shorter acceleration time

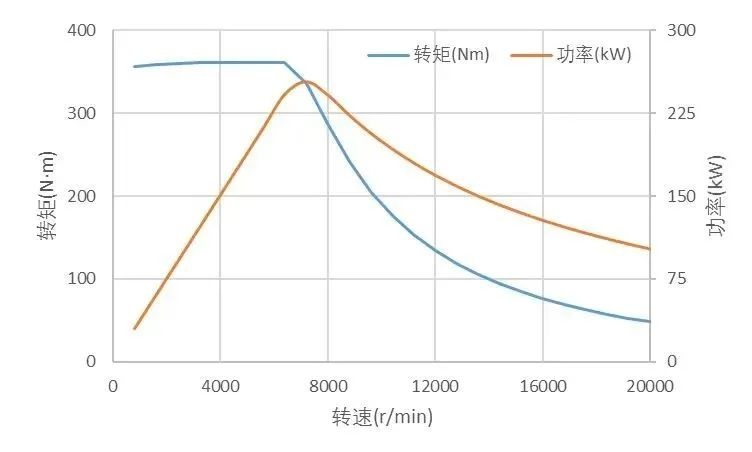

With the same size and the same voltage and current input, the peak torque is increased by 9%, and the peak power is increased by 25%.

-

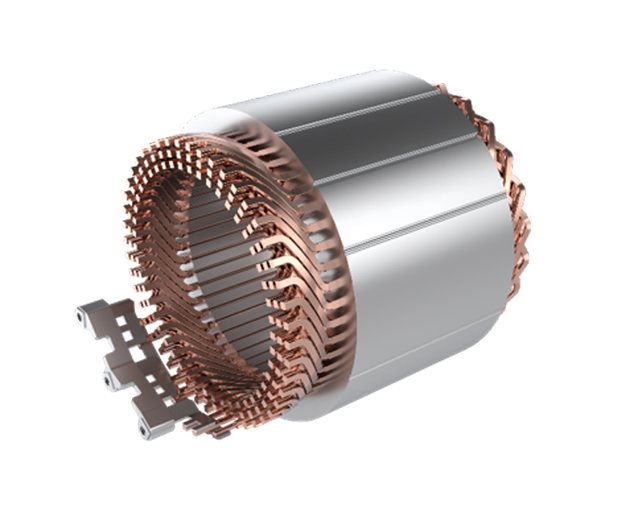

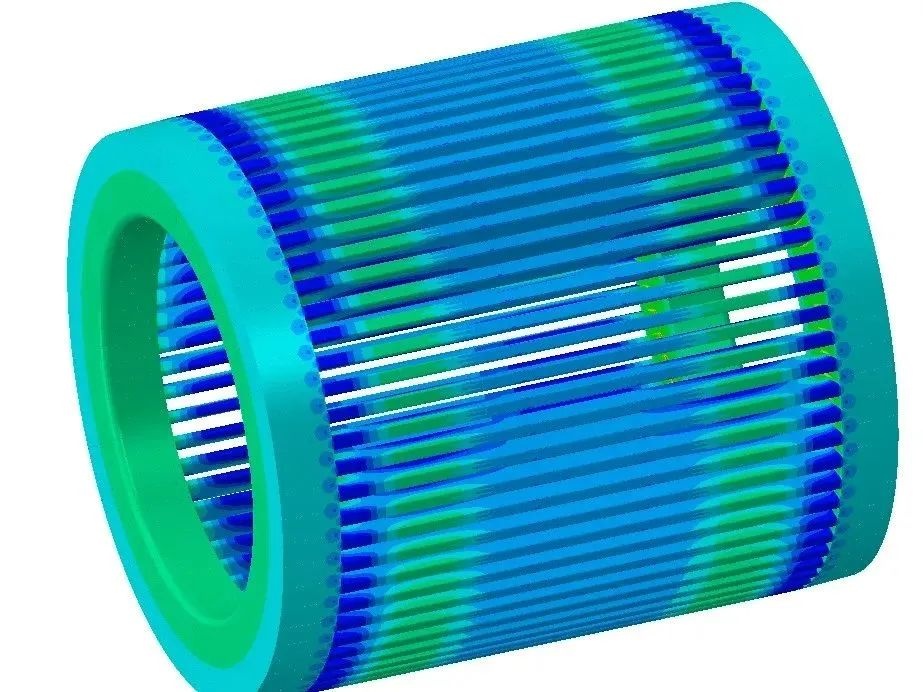

The flat wire solution has a higher split ratio, and a smaller ratio of leakage inductance to mutual inductance. Under the same size and same voltage and current input conditions, the peak torque is increased by 9%, and the acceleration performance at low speed is better. It is tailor-made for auxiliary drive;

-

4 pairs of poles scheme design, compared with the mature 2 pairs of poles scattered wire scheme in the industry, the end winding span is small, less copper is used and less heat is generated. In addition, the heat dissipation at the end of the hairpin winding in the oil cooling scheme is better, and the continuous working condition capability and frequent acceleration and deceleration capabilities are further enhanced, effectively supporting the multiple rapid acceleration and deceleration requirements of the vehicle;

-

By increasing the thickness of the winding paint, the flat wire can greatly increase the PDIV value, improve the insulation reliability, meet the needs of the high-voltage vehicle platform, and realize the extraordinary experience of fast charging for 200km after charging for 5 minutes. It can effectively solve the problem that the PDIV value of loose wire windings has limited room for improvement and it is difficult to meet the insulation requirements of 800V high-voltage platforms;

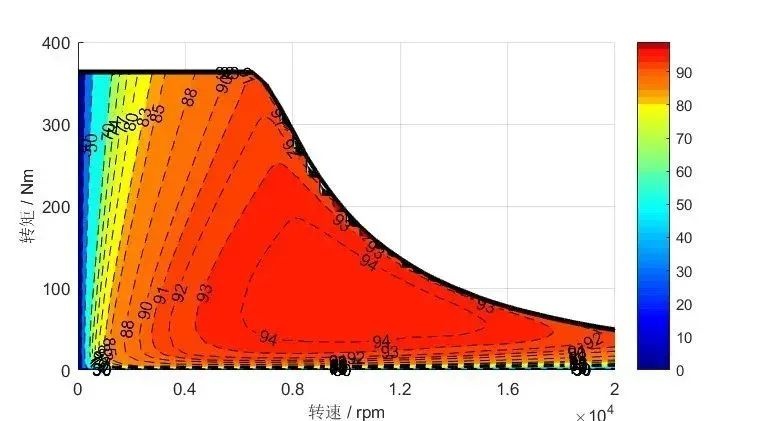

02 Small dragging loss, high operating efficiency and longer battery life

The drag loss is less than 2kW, the maximum efficiency of the motor is increased by more than 1.5%, and the cruising range of the vehicle is increased by more than 2%.

-

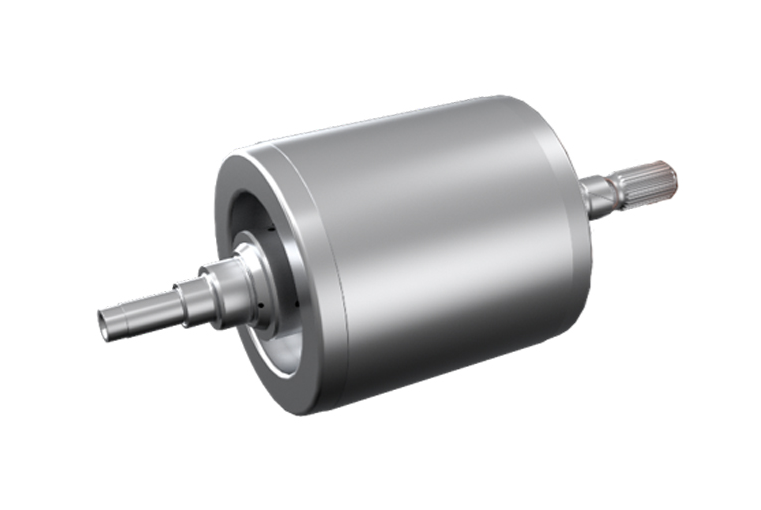

Innovative use of new cast aluminum alloy material, conductivity ≥ 50% IACS, effectively reducing the resistance value of the rotor aluminum strip;

-

Multi-layer card issuance scheme design, the slot full rate has been greatly increased to about 70%, and the peak efficiency of the motor has increased by more than 1.5% compared with the industry's loose line scheme;

-

Cooperate with the asynchronous motor assembly to optimize the mechanical loss in multiple dimensions, including the development of a small aspect ratio solution, the precise optimization of the cooling oil circuit and the flow rate, etc., effectively reducing the zero torque loss of the assembly, dragging loss below 2kW@15krpm, and effectively improving the cruising range of the vehicle2 %above;

03 Higher power density, smaller size and lighter weight

The power density of the motor is increased by 20%, and the weight of the whole vehicle is reduced by 10kg.

-

Yield strength ≥ 90Mpa, the maximum speed of the platform is 20krpm, the power density is 20% higher than that of the industry's 16krpm loose wire motor solution, and the weight of the whole vehicle is reduced by 10kg;

-

Optimize the height of the end wire package, which is more than 5mm lower than the traditional loose wire, and further improve the power density of the motor;

-

The peak speed of the motor reaches 20krpm, matching the peak speed of customer A up to 250km/h, which meets the export demand of overseas models and lays the foundation for subsequent models to expand overseas markets; -

XINDA

XINDA