Lecture 5 on Basic Knowledge of Motors-stepper motor

stepper motor

1. Introduction

The stepper motor is an open-loop control element stepper motor that converts electrical pulse signals into angular displacement or linear displacement. In the case of non-overload, the speed and stop position of the motor only depend on the frequency and number of pulses of the pulse signal, and are not affected by the load change. When the stepper driver receives a pulse signal, it will drive the stepper motor to press The set direction rotates a fixed angle, which is called "step angle", and its rotation runs step by step at a fixed angle. The angular displacement can be controlled by controlling the number of pulses, so as to achieve the purpose of accurate positioning; at the same time , the speed and acceleration of the motor rotation can be controlled by controlling the pulse frequency , so as to achieve the purpose of speed regulation.

2. Working principle

The stepper motor is a kind of induction motor . Its working principle is to use the electronic circuit to convert the direct current into a time-sharing power supply. The multi-phase sequence controls the current. Using this current to power the stepper motor, the stepper motor can work normally. The driver is the time-sharing power supply for the stepper motor, and the multi-phase sequence controller

The stepper motor must be used in a control system composed of a double-ring pulse signal and a power drive circuit. Therefore, it is not easy to make good use of stepper motors . It involves many professional knowledge such as machinery, motors, electronics and computers.

3. Classification

Stepper motors include reactive stepper motors ( VR ), permanent magnet stepper motors ( PM ), hybrid stepper motors ( HB ) and single-phase stepper motors.

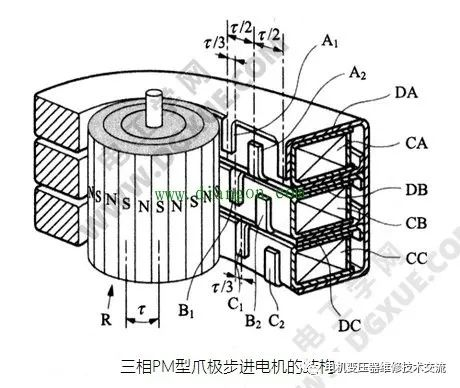

1. Permanent magnet stepper motor

Permanent magnet stepping motors are generally two-phase, with small torque and volume, and the step angle is generally 7.5 degrees or 15 degrees; permanent magnet stepping motors have large output torque and good dynamic performance, but the step angle is large.

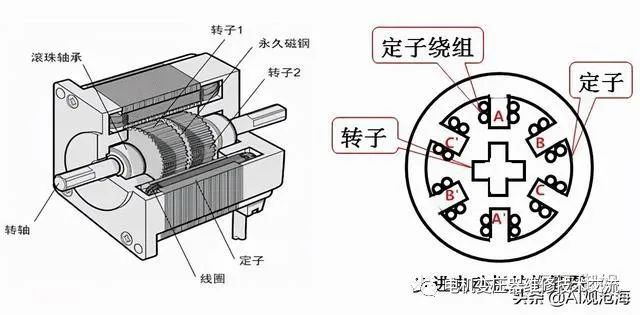

2. Reactive stepper motor

Reactive stepper motors are generally three-phase, which can achieve high torque output, and the step angle is generally 1.5 degrees, but the noise and vibration are very large. The rotor magnetic circuit of the reactive stepper motor is made of soft magnetic materials, and the stator has multi-phase excitation windings , which use the change of magnetic permeability to generate torque.

The reactive stepper motor has simple structure, low production cost and small step angle; but its dynamic performance is poor.

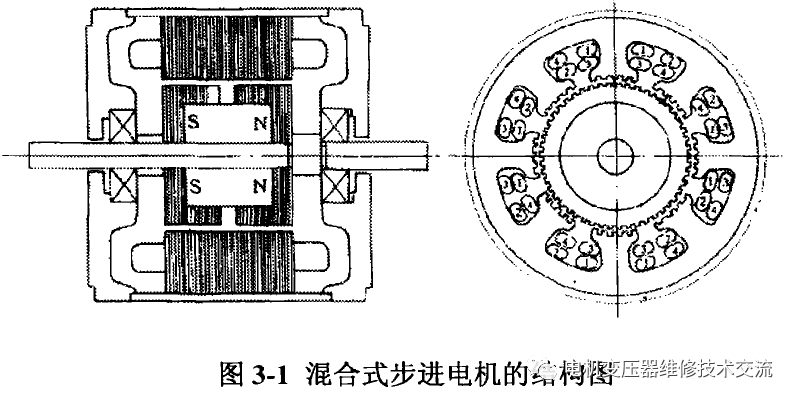

3. Hybrid stepper motor

The hybrid stepping motor combines the advantages of both reactive and permanent magnet stepping motors. It has a small step angle, large output, and good dynamic performance. It is the stepping motor with the highest performance at present. It is also sometimes called a permanent magnet induction stepper motor. It is divided into two-phase and five-phase: the two-phase step angle is generally 1.8 degrees and the five-phase step angle is generally 0.72 degrees. This type of stepper motor is the most widely used.

XINDA

XINDA