![]()

1. How to improve the efficiency of the motor?

Someone asked: What are the ways of high-efficiency motors? Is it not as simple as using more materials? I have been selling motors for many years, and I have never been under such great pressure recently. I clearly feel that customers are becoming more and more demanding on motors, especially in terms of high efficiency and energy saving. Yes, after all, each company has cost pressure. High-efficiency motors are indeed more than just using more materials. To some extent, multi-purpose materials may be the main factor restricting efficiency improvement .The pressure of energy and environmental protection is forcing the motor to upgrade its efficiencyThe energy crisis and environmental protection issues have become the barometers of the normal operation of various industries, and people are paying more and more attention to the efficiency of energy utilization. Although electric motors are already very efficient at converting electrical energy into mechanical energy, there is no end to achieving maximum efficiency. In order to match the motor reasonably with the application, it is necessary to continuously carry out design optimization and technological innovation, so as to achieve high efficiency→ultra-high efficiency→ultra-ultra-high efficiency.How to improve motor efficiency?The study of motor efficiency is essentially the process of analyzing various types of losses and figuring out the key factors that affect various types of losses.●Reduce the loss when the current flows through the winding. One of the most straightforward ways to improve motor efficiency is to reduce armature winding losses. For example, by increasing the slot area so that more copper is used to increase the cross-sectional area of the winding and thereby reduce its resistance, the losses when current flows through the winding are reduced.●Core loss control. The core loss is related to two factors: the magnetic flux density and the frequency in the core. Usually the frequency of the power supply is fixed, so in order to reduce the loss of the iron core, the method of lengthening the iron core is generally adopted.●Efficiency improvement is closely related to material consumption. In order to achieve the required energy consumption level, it is inevitable to increase the amount of copper used and the volume of the iron core. But the reduction in loss is not always positively correlated with the increase in copper and iron consumption. When the cross section of the iron core and coil increases to a certain extent, the loss will increase instead, because the increase in the volume of the iron core will also increase the loss of the iron core and coil. If it exceeds the reduction caused by the decrease in resistance and the unsaturated iron core, the efficiency On the contrary, it decreases. There may be a point beyond which losses actually increase when the core volume is increased. Similarly, for a given flux density, eddy current losses can be reduced by using thinner laminations.

●Technological innovation improves efficiency. Break through the closed-slot rotor and cast copper rotor and other technical forbidden areas, and the efficiency level of the motor will achieve a qualitative leap.Efficiency improvement is not as simple as using multiple materialsEfficiency improvement will indeed come at the cost of more effective material consumption, but due to the existence of effective materials such as copper wires and iron cores, various losses are inevitable. The product of the loss value per unit of material and the total amount of material consumption is relatively certain There is always a minimum value under stable conditions. The process of achieving the minimum value or optimizing the design is a traditional method of improving efficiency. How to improve relatively stable conditions or improve material grades and break through the bottleneck of traditional technology depends on innovative technologies.

2. Analysis of the reasons for the low efficiency of the motor

● The resistance of the stator winding is large : (1) The wire resistivity is large or the wire diameter is small, the wire diameter is uneven or the number of parallel windings is small; (2) the wiring is wrong or the welding is not strong; (3) the actual number of turns is more than the design value.The stator current is large : (1 ) other losses are large; (2) the three-phase imbalance is caused by the asymmetry of the stator winding; (3) the air gap between the stator and the rotor is seriously uneven; (4) because the number of turns is less than the normal value, this When the resistance will be less than the normal value; (5) winding wiring is not correct.● The resistance of the rotor winding (or guide bar) is large : (1) the resistivity of aluminum (copper) is relatively large; Thin strip problem; (3) The stator slot is not neat (expressed as notch sawtooth), there are wrong pieces and reversed pieces, resulting in insufficient effective area of the rotor slot; (4) The structure of aluminum is loose due to improper selection of cast aluminum parameters, directly This leads to an increase in resistivity; (5) The material does not meet the requirements, such as the use of alloy aluminum for ordinary aluminum rotors; (6) The use of wrong rotors, etc.● The rotor current is large; (1) The wrong rotor is used; (2) The wrong aluminum is used when casting aluminum, for example, the alloy aluminum rotor uses ordinary aluminum; Cause excessive rotor transverse current.● Improper choice of stator winding type or pitch;● Improper selection of stator and rotor slot fit;● The air gap is too small or seriously uneven;● Serious short circuit between the rotor guide bar and the iron core;● Stator winding ends are too long, etc.● The quality of silicon steel sheets is poor or the materials are used incorrectly, for example, 600 materials are used instead of 800 grades; motor factories that purchase iron cores should pay special attention to this problem.● Insulation between stator core sheets is not good: (1) The insulation treatment is not carried out or the treatment effect is not good; (2) When the iron core is laminated, the pressure is too high, which damages the insulation between the sheets; (3) The bore of the stator is turned or the file is repaired When the iron core is removed, it will cause a short circuit between the core pieces and the pieces (this problem exists in most iron core manufacturers).● Insufficient number of iron core pieces and insufficient iron weight: (1) Insufficient number of chips (missing pieces); (2) The stacking pressure is small and not compacted, and the direct result is insufficient iron weight; (3) The burr on the punched sheet is large , The iron weight cannot be guaranteed when the iron length meets the requirements; (4) The paint is too thick, which is a direct quality problem of the silicon steel sheet.● The magnetic circuit is too saturated, and the relationship curve between no-load current and voltage is seriously bent.● The no-load stray loss is relatively large, because it is included in the iron loss during the test, which makes the iron loss appear larger.● When the winding is removed by fire or electric heating, the iron core will be overheated, the magnetic conductivity will be reduced and the inter-chip insulation will be damaged. This problem mainly occurs when the winding is taken out by fire after the winding is faulty; some motor manufacturers have found a way to take out the winding by soaking in lye.● The quality of the bearing or bearing assembly is not good. At this time, the bearing will be seriously heated or rotate inflexibly.● The external fan is used wrongly (for example, a 4-pole fan is used for a 2-pole motor) or the blade angle is wrong; according to the conventional design, the fan of a 2P motor is relatively small, and the method of reducing loss by adjusting the fan is very effective, but the premise is that Ensure the temperature rise performance of the motor.● The machine base and the bearing chambers of both end covers are not in the same axis;● The diameter of the bearing chamber is small, which causes the outer ring of the bearing to deform under pressure, resulting in increased friction loss of the bearing; this situation may also lead to overheating and failure of the bearing.● There is too much lubricating grease in the bearing chamber or the quality of the lubricating grease is not good. This problem is obvious on high-voltage motors. Ms. Shen once did a test, and the highest point of the bearing cap temperature was 10K higher than the lowest point. Open it and check that there is indeed a lot of grease accumulation at this position.● Stator and rotor rub against each other, which is what we call sweeping. When the stator and rotor rub against each other, it will not directly cause the motor to stop rotating, but the loss of the motor will increase significantly.● The axial size of the rotor is not correct, causing the two ends to be stuck, making the rotation inflexible.● Oil seals or water throwing rings and other components are improperly installed or deformed, resulting in large frictional resistance.● With fan motor, the fan rubs against the associated parts, causing the rotation to be difficult.

Further reading: How to define a high-efficiency motor?

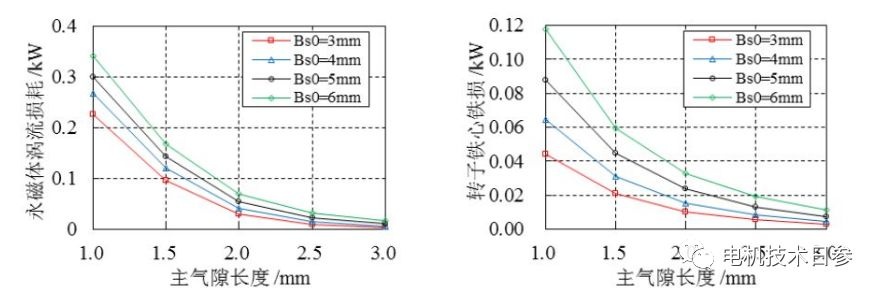

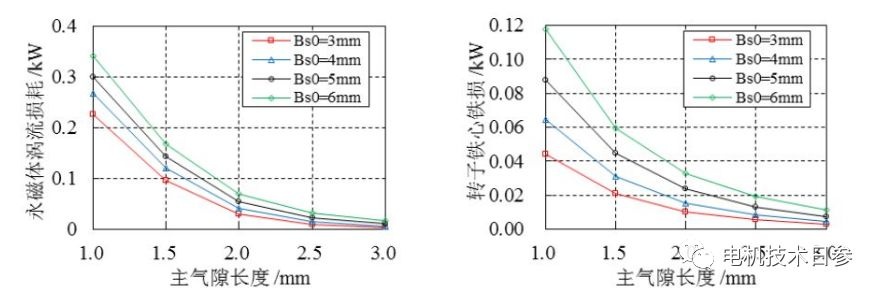

Ordinary motor: The motor is a device that converts electrical energy into mechanical energy. 70%-95% of the electrical energy absorbed by the motor is converted into mechanical energy. This is the efficiency value of the motor, which is an important technical indicator of the motor. The 5% part is consumed by the motor itself due to heat generation, mechanical loss, etc., so this part of electric energy is wasted. High-efficiency motor: A motor with a high utilization rate of electric energy is called a high-efficiency motor, or "high-efficiency motor" for short. For ordinary motors, it is not easy to increase the efficiency by 1 percentage point, and the material will increase a lot, and when the efficiency of the motor reaches a certain value, no matter how much material is added, it cannot be improved. Most of the high-efficiency motors on the market are replacement products of three-phase asynchronous motors, that is to say, the basic working principle has not changed.The high-efficiency motor mainly improves the efficiency of the motor through the following ways: 1. Increase the outer diameter of the iron core, increase the length of the iron core, increase the size of the stator groove, and increase the weight of the copper wire to achieve the purpose of improving efficiency. For example, the outer diameter of the Y2-8024 motor is increased from the current Φ120 to Φ130. The increase of Φ145, while increasing the length from 70 to 90. The amount of iron used for each motor increases by 3Kg. The amount of copper wire increases by 0.9Kg. 2. Silicon steel sheet with good magnetic conductivity is used. In the past, hot-rolled sheet with large iron loss was used, but now high-quality cold-rolled sheet with low loss is used, such as DW470. Even lower DW270. 3. Improve machining accuracy and reduce mechanical loss. Replace the small fan to reduce fan loss and use high-efficiency bearings. 4. Optimize the design of the electrical performance parameters of the motor, and optimize the parameters by changing the groove shape. 5. Adopt cast copper rotor (complicated process and high cost). Therefore, to make a real high-efficiency motor, the cost of design, raw materials, and processing is much higher, so that the electricity can be converted into mechanical energy to the greatest extent.Energy-saving measures for high-efficiency motors Motor energy saving is a systematic project, which involves the whole life cycle of the motor. From the design and manufacture of the motor to the selection, operation, adjustment, maintenance, and scrapping of the motor, the effect of energy-saving measures must be considered from the entire life cycle of the motor. Domestic In this aspect, the main consideration is to improve efficiency from the following aspects. The design of energy-saving motor refers to the use of modern design methods such as optimization design technology, new material technology, control technology, integration technology, test and detection technology to reduce the power loss of the motor, improve the efficiency of the motor, and design an efficient motor. When the motor converts electrical energy into mechanical energy, it also loses a part of energy. Typical AC motor losses can generally be divided into three parts: fixed loss, variable loss and stray loss. Variable loss varies with load, including stator resistance loss (copper loss), rotor resistance loss and brush resistance loss; fixed loss has nothing to do with load, including iron core loss and mechanical loss. The iron loss is composed of hysteresis loss and eddy current loss, which is proportional to the square of the voltage, and the hysteresis loss is also inversely proportional to the frequency; other stray losses are mechanical losses and other losses, including friction losses of bearings and fans, rotors and other windage losses due to rotation.

Features of high-efficiency motors1. Save energy and reduce long-term operating costs. It is very suitable for textiles, fans, water pumps, and compressors. The motor purchase cost can be recovered by saving electricity for one year;2. The asynchronous motor can be completely replaced by starting directly or adjusting the speed with a frequency converter;3. The rare earth permanent magnet high-efficiency energy-saving motor itself can save more than 15℅ of electric energy than ordinary motors;4. The power factor of the motor is close to 1, which improves the quality factor of the power grid without adding a power factor compensator;5. The motor current is small, which saves power transmission and distribution capacity and prolongs the overall operating life of the system;6. Power-saving budget: Taking a 55Kw motor as an example, the high-efficiency motor saves 15% of electricity compared with ordinary motors, and the electricity fee is calculated at 0.5 yuan per kilowatt-hour. Using an energy-saving motor can recover the cost of replacing the motor by saving electricity within one year.

XINDA

XINDA