RV reducer model speed ratio and application range analysis

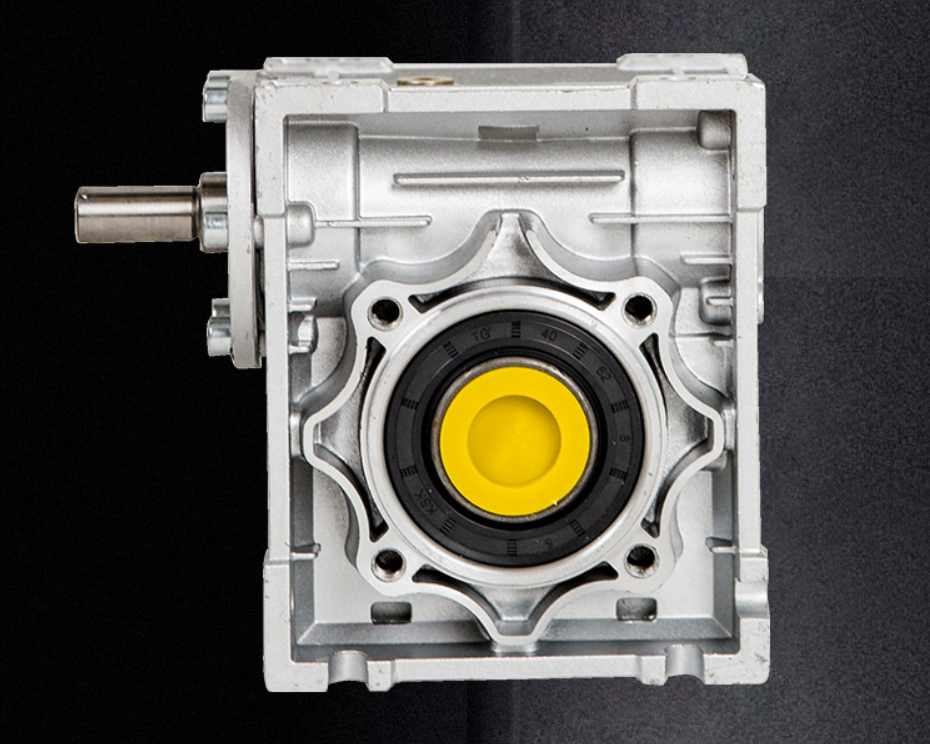

The NMRV reducer is relatively light in weight. The shell is made of aluminum alloy. It has the advantages of light weight, superior strength, beautiful appearance, high heat dissipation performance,longlifeis convenient and simple to connectwith the motor. Easy to install. NMRV reducer is a more practical transmission equipment, and its appearance design and its body aremore in line with the needs of the public than other types of reducers.

Although the RV reducer made of aluminum alloy only emerged in 2007, its application field and popularity are superior to other types of reducer. It is a reducer with high practicability. It is the integration of domestic and foreign technologies. The NMRV reducer is very convenient to connect with ordinary motors, stepless speed changers, and flange electromagnetic clutch brake groups, and does not need a coupling to connect. It is suitable for installation, and the output torque is relatively large, and the work is quite stable.

1. The operating environment of NMRV reducer is lower than -30°C or higher than 60-30°C, and the oil seal of special material must be replaced;

2. The motor matched with the NMRV reducer must be suitable for working in a low temperature environment, and the power of the motor must meet the torque requirements when starting at low temperature;

3. The viscosity of the lubricating oil will be high before it is ready to be put into use, so the machine should be allowed to run without load before loading to avoid equipment failure;

4. When using the NMRV reducer, replace the lubricating oil after 150-400 hours of operation, and the subsequent oil change reducer cycle is less than or equal to 4000 hours;

5. Regularly check the quantity and quality of the oil, keep enough lubricating oil, and replace the oil mixed with impurities or deteriorated in time. The service factor of the NMRV reducer depends on the actual working environment. When choosing an appropriate service factor, factors such as the nature of the load at the output end, the daily operating time, and the frequency of startup must be considered.

Center / center distance: 25 30 40 50 63 75 90 110 130 (unit: mm).

Output hole /shaft diameter: 11, 14, 18, 25, 28, 35, 42, 45 (in mm)

1 to 5, 1 to 7.5, 1 to 10, 1 to 15, 1 to 20, 1 to 30, 1 to 40, 1 to 50, 1 to 60, 1 to 80, 1 to 100 (single-stage transmission ratio, double level is calculated separately). Models are: NMRV025, NMRV030, NMRV040, NMRV050, NMRV063, NMRV075, NMRV090, NMRV110, NMRV130, NMRV150

Motor power: 0.06KW-7.5KW

Scope of application: used in food, packaging, textile, medical, printing, conveying, machine tool, leather, glass, ceramics, chemical industry, light industry and other mechanical deceleration devices, especially suitable for all kinds of automatic wire transmission reducers.

XINDA

XINDA