Analysis of new energy vehicle drive motor

1 Basic characteristics of the drive motor

Drive motor: a motor used in electric vehicles to drive the wheels for motion. The basic principle is to realize electromechanical energy conversion or transmission through electromagnetic induction.

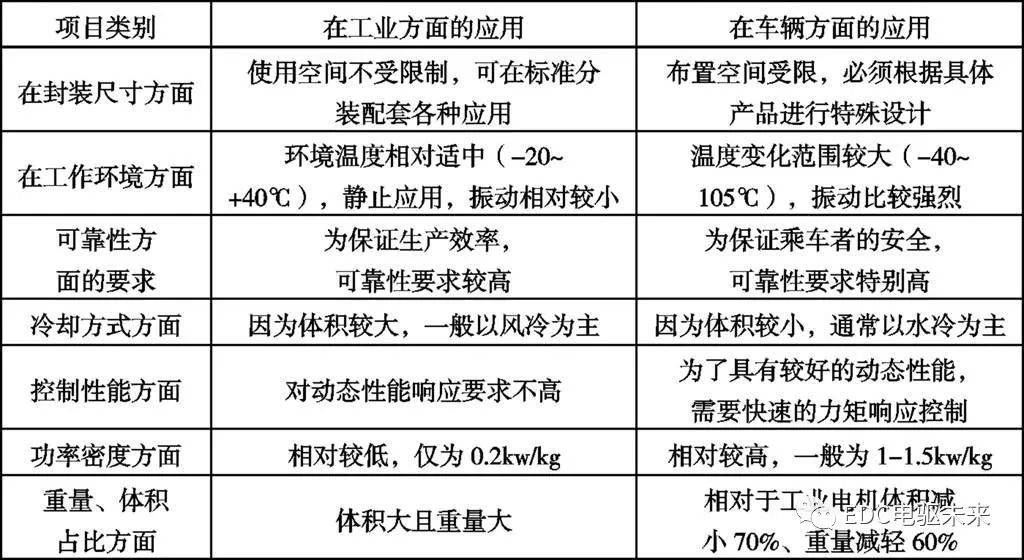

In order to meet the performance requirements of comfort, economy, power, cruising range and cost performance when driving, there are significant differences between vehicle motors and industrial motors, as follows:

Table 1 Differences between vehicle motors and industrial motors

Therefore, the basic characteristics of vehicle motors are as follows:

(1) Small size and light weight. high power torque density

Torque density and power density refer to the maximum torque volume ratio and the maximum power volume ratio respectively. On the basis of satisfying the mechanical strength, lightweight materials such as aluminum alloy should be used as much as possible to reduce the weight; components such as controllers should also be integrated as much as possible to reduce the volume.

(2) High efficiency and wide efficient area

It should have a higher mileage after a single charge, and can adapt to more complex road conditions and driving styles during the entire driving process, and should also have higher working efficiency at lower loads, that is, the efficient working area should be wider.

(3) It has a large starting torque and a wide range of speed regulation

In order to adapt to the torque and power required by the complex working conditions such as frequent starting, acceleration, constant speed driving, deceleration, load, load climbing, overtaking, braking, etc., to reduce the driver's manual work intensity and improve driving comfort, and to achieve the same control response performance as internal combustion engine vehicles, therefore, the motor must have automatic speed regulation characteristics.

(4) High security

In order to reduce the working current of the high-voltage part, reduce the size of the motor and wires, reduce the cost of the inverter and improve the energy conversion efficiency, within the safe range allowed by the national standard, high-voltage power should be used for output as much as possible. Therefore, The operating voltage of the drive motor and battery is relatively high.

(5) Energy conversion

It can convert electrical energy into mechanical energy, and can also recycle mechanical energy and convert it into electrical energy.

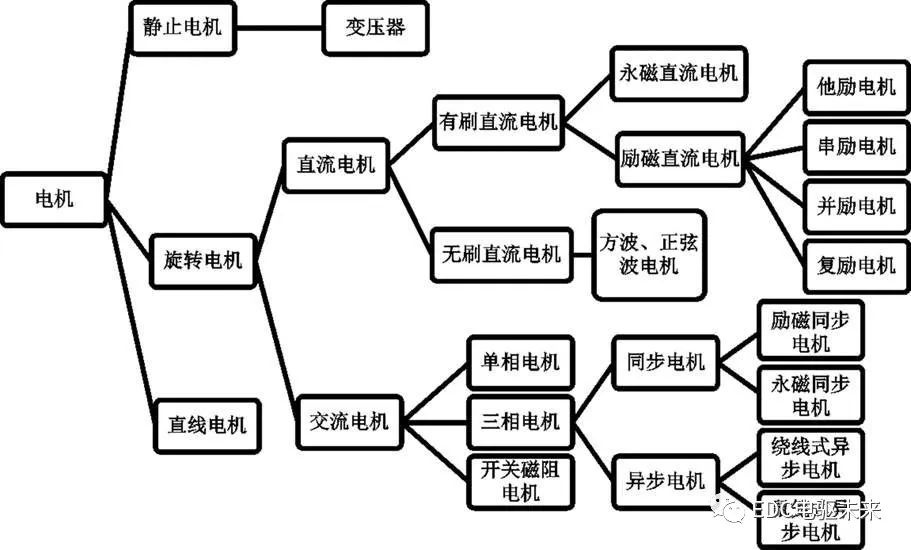

2 Classification of drive motors

Figure 1 Classification of drive motors

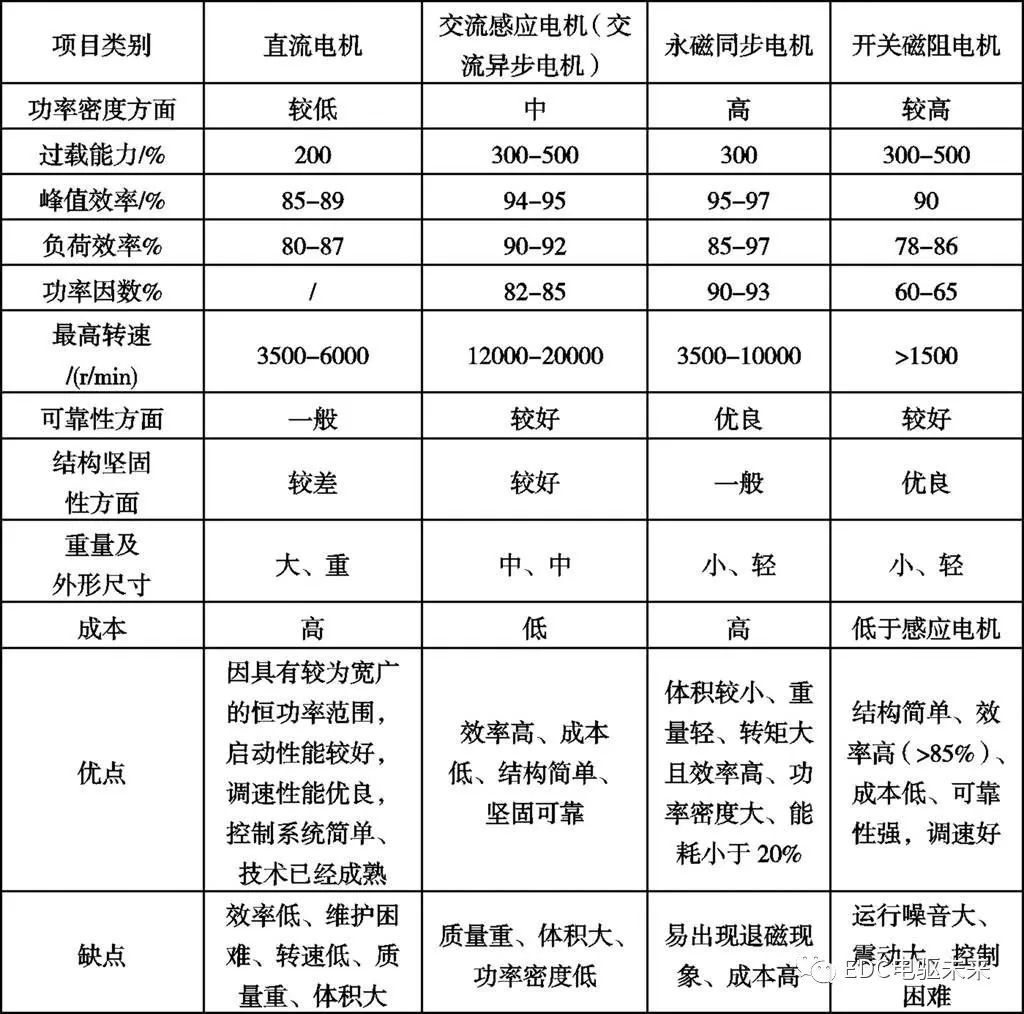

Currently commonly used motors are brushless DC motors, permanent magnet synchronous motors, squirrel cage asynchronous motors, and switched reluctance motors. The performance comparison of four common motors is shown in Table 2.

Based on various comparisons, AC induction motors and permanent magnet synchronous motors are currently widely used in electric vehicles. The following focuses on the permanent magnet synchronous motor.

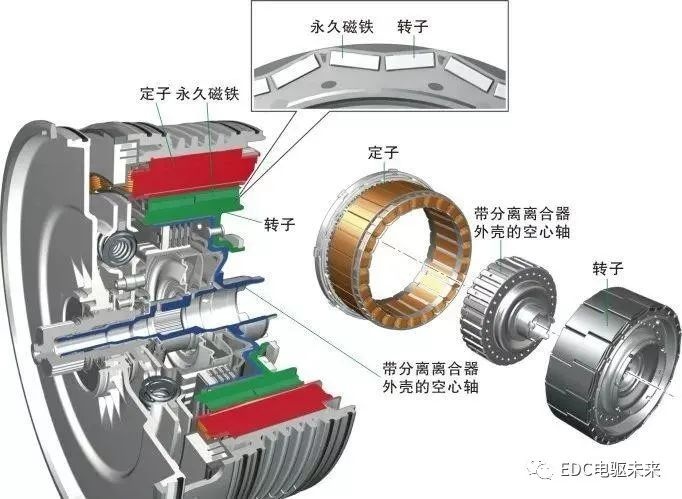

3 Structure of permanent magnet synchronous motor

A synchronous motor that is excited by permanent magnets to generate a synchronous rotating magnetic field is called a permanent magnet synchronous motor. The permanent magnet is used as the rotor part to generate a rotating magnetic field, and the three-phase stator winding generates a three-phase symmetrical current through armature reaction and induction under the action of the rotating magnetic field. The permanent magnet synchronous motor is used as a generator (G) to convert the mechanical energy (kinetic energy) of the rotor into electrical energy; since the three-phase stator has a difference of 120 in space, when three-phase symmetrical current is input on the stator side, the three-phase stator The current will generate a rotating magnetic field in space, and the rotor will be moved by the electromagnetic force in the rotating magnetic field. At this time, the electric energy is converted into kinetic energy, and the permanent magnet synchronous motor can be used as a motor (M).

Table 2 Performance comparison table of four common motors

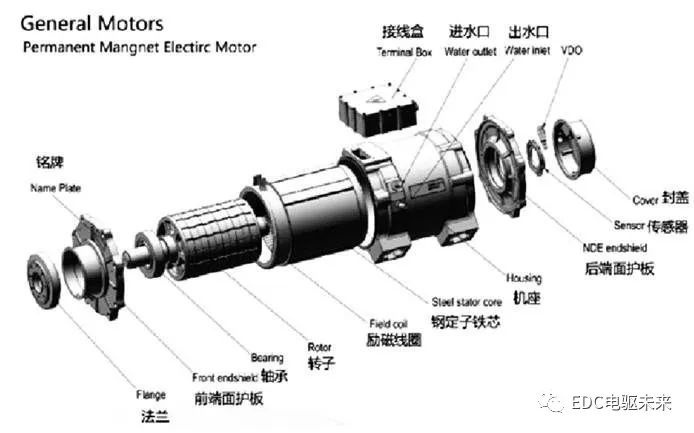

Generally, the stator, rotor, end cover, and various sensors are sub-packaged to form a permanent magnet synchronous motor. The stator structure of the permanent magnet synchronous motor is very similar to that of an ordinary induction motor, but the rotor part of the permanent magnet synchronous motor is very different from other motors - there are permanent magnet poles with better quality on the rotor. According to the placement of permanent magnets on the rotor, permanent magnet synchronous motors are generally divided into three categories: surface-mounted, embedded and plug-in.

Stator: The stator is mainly composed of iron core and coil; the stator core is formed by lamination of punched sheets; the enameled wire is wound into a coil, embedded in the core slot, and then insulated; the insulated core is inserted into the casing to obtain the stator.

Rotor: The rotor is made of iron core, magnetic steel and shaft.

Figure 2 Permanent magnet synchronous motor structure

Magnetic steel (NdFeB): The magnetic flux of the motor is provided by the magnetic steel, which has the greatest impact on the performance of the motor; NdFeB magnets are made by powder metallurgy, which is the magnetic material with the highest magnetic performance; the advantages are high resistance to demagnetization and high cost performance. The disadvantage is that the temperature dependence is relatively strong, the corrosion resistance is relatively weak, and proper coating or electroplating treatment is required.

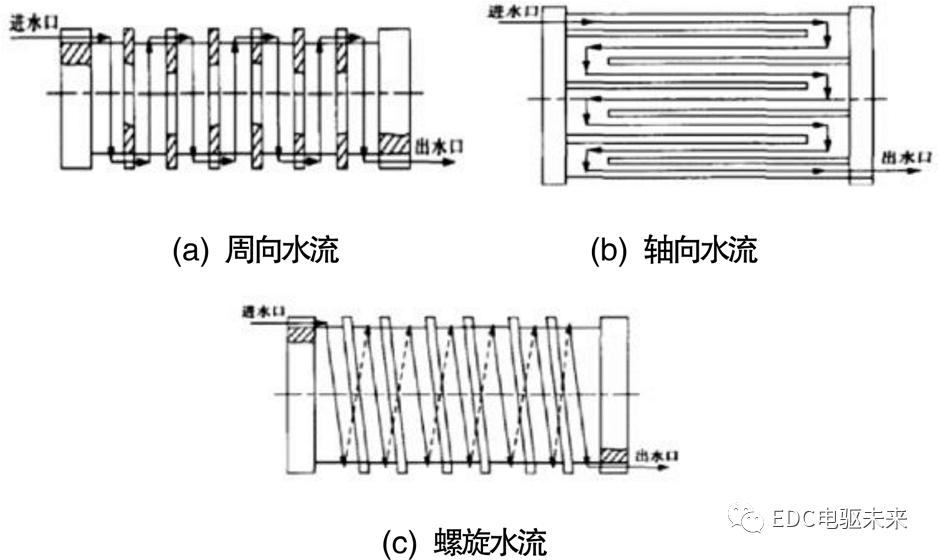

Machine base: Due to the large power and small size of the motor, it generates a lot of heat. In order to facilitate heat dissipation, the machine base contains cooling channels. Common forms of waterways are as follows:

(1) Axial channel (Z-shaped)

The 180-degree direction at the corner of the cooling water channel is likely to cause a large energy loss, and a large inlet water pressure needs to be provided.

(2) Circumferential water channel (spiral tube type)

In order to generate a temperature gradient at the inlet and outlet ends of the motor and form a temperature difference, the water inlet and outlet of the cooling water are generally designed at the left and right ends of the motor.

Figure 3 Cooling channel form of machine base

Punching: The speed range of the automobile motor is wide. Since the change rate of the magnetic flux in the stator core is proportional to the speed of the motor, the alternating frequency of the magnetic field in the iron core is relatively high, and the unit loss is proportional to the power of 1.3~1.5 of the frequency. . Due to the need to maintain high power density, the magnetic flux density in the iron core is the same, and the unit iron loss of the high-speed motor will increase dramatically. In order to reduce iron loss, it is necessary to use low-loss iron core materials.

4 Motor Control System

The main features and functions of the motor drive system are introduced:

(1) As one of the three core components of electric vehicles, the motor drive system is the main actuator for vehicle driving and plays a decisive role in the main performance indicators of the vehicle. The motor drive system directly affects the comfort, power and economy of the vehicle .

(2) Three-phase AC permanent magnet motor (DM) and motor controller (MCU) are used to adjust the output current and motor speed. The motor and motor controller adopt water cooling to prevent excessive temperature.

(3) The vehicle controller (VCU) must be able to issue various operating instructions according to the driver's intentions, and the motor controller completes the response and provides feedback, so as to adjust the output of the driving motor in real time and realize various driving functions of the vehicle.

The main functions of the motor controller (MCU) are as follows:

1) Idling (creep)

2) Control the motor to rotate forward (forward)

3) Control the motor to reverse (reverse)

4) Energy recovery (AC to DC)

It is another important function of the motor controller to perform real-time state and fault detection, communication, protection and fault feedback on the drive motor system.

5 Development trend of drive motor

5.1 Integration

In terms of motors: the motor can be integrated with the engine, transmission assembly and controller to the greatest extent.

In terms of controllers: more and more power electronic assemblies (controllers, power devices, sensors, power supplies, etc.) will be launched, which is also the trend of mass production, generalization and modularization in the future.

5.2 Permanent magnetization

The drive control system with vector control is used to achieve a wider range of speed regulation. Permanent magnet motors have the advantages of high torque density and power density, large specific power, high efficiency, high power factor, high reliability and easy maintenance. Permanent magnetization will become one of the important directions of motor development.

5.3 Digitization

Use software to replace the hardware part to the greatest extent to realize communication, diagnosis, protection, monitoring and other functions. Digitalization of the control system is an inevitable trend in the development of motor drive technology.

6 Technical level of drive motors at home and abroad

On the whole, my country's drive motors have made great progress, and have independently developed products that meet the needs of various new energy vehicles. Some of the main performance indicators have reached the international advanced level of the same power level. However, there is still a certain gap with foreign countries in terms of peak speed, power density and efficiency.

Table 2 Comparison of permanent magnet synchronous motor parameters of domestic and foreign drive motor companies

In terms of technical indicators, there are still gaps in the following aspects between domestic motors and foreign motors:

① Peak speed

The peak speed is an important indicator of the drive motor, and it is also the most obvious indicator of the gap between the domestic drive motor and the foreign motor. The peak speed of most permanent magnet synchronous motors in China is below 10,000 rpm, while that in foreign countries is above 10,000 rpm.

② Power density

Although domestic motors can basically reach the international level in terms of power, there is a weight disadvantage under the same power condition, so there is a big gap in power density compared with the international level. At present, the power density of permanent magnet synchronous motors in China is mostly in the range of 1 to 2 kw/kg, which is far from the target value of 3.5 kw/kg in 2020.

③ Efficiency

In terms of motor efficiency, the highest efficiency of domestic motors has reached 94% to 96%, which has reached the level of Siemens, Remy and other enterprises. However, there is still a certain gap in the area of high-efficiency areas, such as the proportion of areas where the system efficiency is greater than 80%. The proportion of high-efficiency area of motors in my country is concentrated at 70% to 75%, while that of foreign motors basically reaches 80%.

④ Cooling method

The cooling method of motors has gradually developed from natural cooling to water cooling. At present, domestic motor companies mainly use water cooling, and foreign advanced motor companies have developed to oil-cooled motors. Some domestic motor companies have also developed oil-cooled motors, such as Jingjin, which have further improved the cooling efficiency of the motor.

The development bottleneck of permanent magnet synchronous motor

At present, since pure electric passenger vehicles use permanent magnet synchronous motors as the main technical route, how to further improve their performance has become a key issue in the industry. At present, permanent magnet synchronous motors face the following technical difficulties:

① Power density

There are two ways to increase power, one is to increase torque, and the other is to increase speed. The main problem of the former is that the overload current increases, resulting in high heat generation and greater pressure on heat dissipation; the latter is due to the high ferromagnetic loss at high speeds, which requires the use of high-performance low-saturation silicon steel sheets, thereby increasing the cost; or the use of complex rotors structure, but affects power density.

② Materials

Permanent magnet materials are also an important factor restricting the performance improvement of permanent magnet synchronous motors. The commonly used permanent magnet materials NdFeB mainly have disadvantages such as poor temperature stability, irreversible loss, high temperature coefficient, and serious loss of magnetic properties at high temperatures, which affect the performance of motors. performance.

③ Production process

The difficulty in the production process of permanent magnet synchronous motors is an important factor restricting large-scale matching of passenger cars. Because permanent magnet synchronous motor manufacturers lack the accumulation of industrialization, the defective rate of domestic enterprises is relatively high, and they cannot meet the defective rate requirements of passenger car companies, especially with the expansion of the pure electric passenger car market. The annual output has brought great challenges to permanent magnet synchronous motors.

Development of in-wheel motors

① Technical status

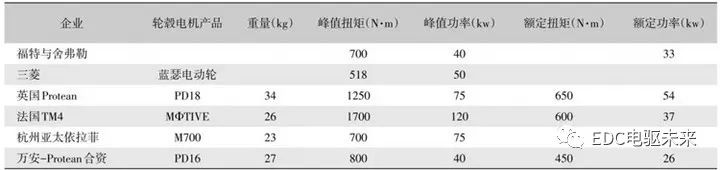

Hub motors were first installed on pure electric vehicles by Porsche in 1900. After more than 100 years of development, not only many American and Japanese OEMs have increased the development of hub motors, but motor companies (such as British Protean, French TM4, etc.) and Tire companies (Michelin, Bridgestone) have also developed in-wheel motor products. Domestically, Vie Technology has a joint venture with British Protean, and Asia Pacific and Slovenian Hub Motor Company have jointly developed hub motor products. The main in-wheel motor products and their parameters at home and abroad are shown in Table 3.

Table 3 Main in-wheel motor products and parameters at home and abroad

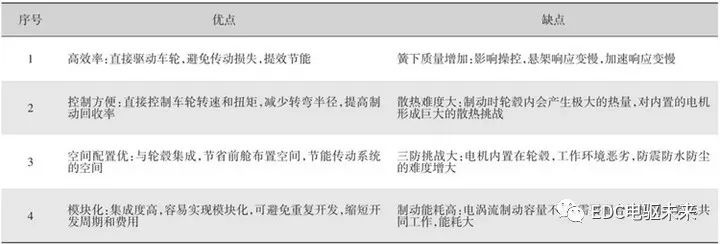

② Analysis of advantages and disadvantages

On the whole, permanent magnet synchronous motors are widely used in hub motors. In recent years, domestic and foreign vehicle and component companies have made many attempts to drive pure electric and hybrid passenger vehicles with in-wheel motors. The advantages and disadvantages of in-wheel motors are shown in Table 4 through comparison.

Table 4 Analysis of advantages and disadvantages of in-wheel motors

③ Performance improvement measures

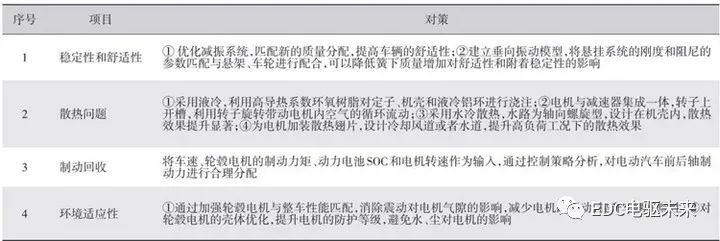

The main problems facing the performance of hub motors are the impact of the improvement of unsprung mass on comfort and handling; the heat dissipation and braking energy recovery problems after integration with the hub, and the subsequent shockproof, waterproof and dustproof Wait. The technical means and countermeasures for major improvements are shown in Table 5.

Table 5 Countermeasures for performance improvement of in-wheel motors

XINDA

XINDA