How motor control can achieve "doing the right thing at the right time"!

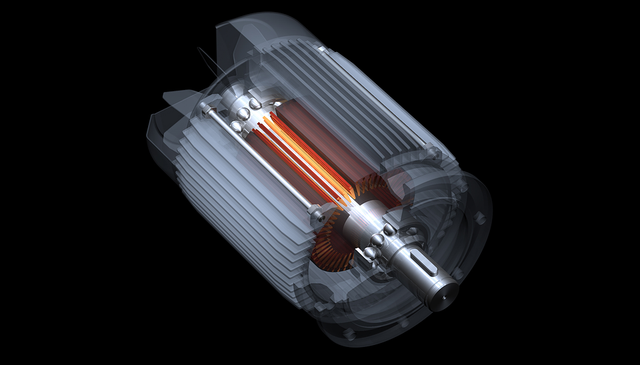

A motor, regardless of its type, needs to be paired with some type of controller, which can vary in characteristics and complexity, depending largely on the capabilities of the particular motor. The simplest example of a motor control mechanism is a conventional switch that connects the motor to its power source. This switch can be a manual controller or a relay connected to an automatic sensor to start and stop the motor.

Preparation for control circuit design

Before facing the "right time", there is still a pre-work of "power transmission" that needs to be prepared, that is, the drive circuit needs to be determined. Its role is how to design a controllable power supply system. It needs the following information to ensure that circuit board design and heat dissipation design, electronic components and other hardware meet the system needs.

The size of the power supply capacity must match the specification of the motor.To receive control commands and operate, it needs to be matched with the controller.Power transmission efficiency, signal and power can be transmitted normally, without interference from other signals or electromagnetic waves.Whether the system can operate normally under the operating environment.Security protection capabilities.

The "right time" can only be determined after a complete drive circuit is in place. Although time is used as a noun, it really means "position", which is the relative position of the motor rotor's rotation, or it can be called an angle.

Τ=1/2π·I·L·D^2·N·Sin(δ)

The above equation is the motor torque formula, where Sin(δ) represents the angle between the current of the motor and the magnetic field, when Sin(90°)=1 is the maximum value, Sin(0°)=0 is the minimum value, in the "right" The angle position "delivers" current "to the motor to achieve the best output effect.

How to be "right at the right time"

To achieve "right time", the first step is to obtain the correct position of the motor rotor, which requires the use of position sensors. However, position judgment will be subject to errors caused by sensor resolution, installation position, signal processing, data transmission, programming calculation, etc. The possible reasons are analyzed as follows:

Insufficient resolution will cause the sensor to be unable to directly mark the location of the power transmission, which needs to be obtained indirectly through signal processing techniques.If you have a sensor with sufficient resolution, you don’t need to worry about the installation problem. On the contrary, if the installation position deviates, the correct position point cannot be directly marked.The sensor provides an electronic signal, which is used to judge the position change by observing the voltage level change. However, all voltage level changes are actually achieved by current transmission. In the sensor circuit, capacitors are often added for filtering and voltage stabilization to stabilize the voltage level, but it will also affect the current working time, making the voltage level take a long time to change, resulting in delays.The electronic signal obtained by the sensor needs to be transmitted to the controller before it can be used. Then, there will be capacitive and inductive elements on the control circuit board, which will affect the time when the electronic signal enters the controller.After the position signal enters the controller, it may need to be calculated or processed, or it may have to wait for other programs to finish running first, resulting in the inability to respond to the position signal immediately.

Several common causes are listed above as a reference. After obtaining the correct position information, it is necessary to send "current" into the motor. It should be noted that "correct time" refers to the time when the current enters the motor. The motor can be regarded as Inductive components, which cause a significant delay in the time for current to enter the motor. In fact, the inductance value in the motor will be changed by the magnitude of the inflow current and the switching frequency (speed) of the power supply. Therefore, the current delay time will also change at different speeds.

In addition, attention should also be paid to the time required for the controller to receive the position signal to process and complete the output control command, as well as the response time and bandwidth of the switching element, which may cause the time to input current to be affected.

How to be a good driver

Ensure the transmission rate of the signal: the delay of the signal is an inevitable result, but if the delay rate is fixed and known, it can be compensated by hardware or software; since the calculation function in the equation is Sin(δ), Therefore, if the difference angle is small, its calculated value is still very close to 1, and the influence is not great. To effectively ensure the signal transmission speed, it is necessary to rely on the ability of circuit design, including the selection of various electronic components, power supply energy allocation and circuit wiring planning, etc.

Software programming ability: The motor driver program does not place a heavy burden on the controller, but the controller needs to handle many tasks at the same time, so the weight, sequence and attention should be paid to mastering the calculation time. If you choose a high-end controller, its calculation response speed is fast, and you don't need to worry about the problem of delaying each other's time. For low-level controllers, it is necessary to pay attention to the compilation of the program. It may be necessary to directly use the assembly language to write the program code to achieve the shortest program execution time.

The overall comprehension of the motor system: A deep understanding of the motor is still required for motor drive. At present, most electronic circuit systems are used for control and processing of voltage signals. First, the current value is not large. Second, the loss and The influence of electromagnetic waves. In the motor system, the current is the direct source of the torque force, and the importance of observing the change of the current is far more than that of the voltage. The inductance and electromagnetic waves generated in the motor are much larger than the electronic circuit system. If not properly considered, it is very likely that it will be fed back into the drive circuit and directly cause adverse effects. Furthermore, the environment in which the motor is used is relatively harsh, and special attention must be paid when placing the circuit directly inside the motor.

in conclusion

Depending on the application of the motor, the controller can provide different functions, they help the motor start under low voltage conditions, allow multiple speeds or reverse control operation, protect against overcurrent and overload faults, and perform various other functions. Some complex motor controls also help to efficiently control the speed and torque of the motor, and may also be part of a closed-loop control system responsible for the precise positioning of the motor-driven machine.

XINDA

XINDA