Why do motors of the same specification have high efficiency but low temperature rise?

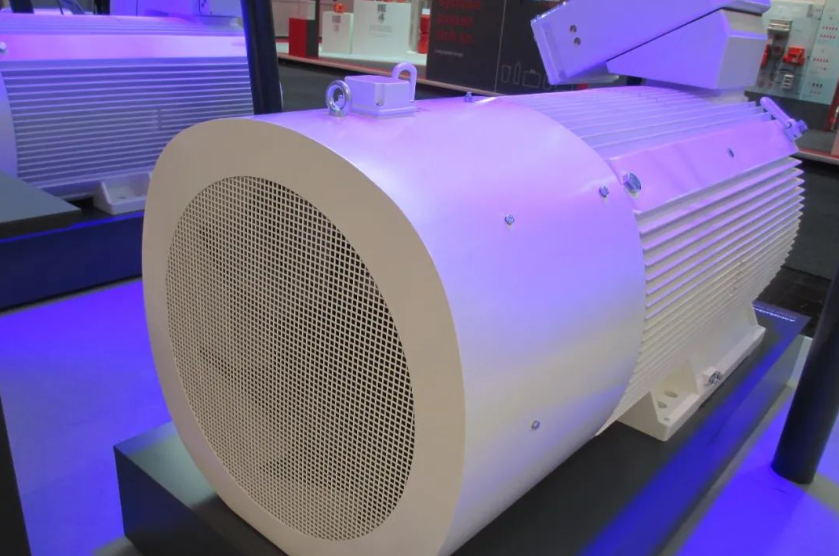

The most effective way to improve the efficiency of the motor is to reduce various losses. From the characteristics of the parts of the high-efficiency motor that are most directly different from those of the ordinary motor, it can be found that the fan of the high-efficiency motor is relatively small, and the corresponding hood shape is also different from the simple cylindrical shape. , but a conical shape that matches the fan, its purpose is to effectively control the mechanical loss during the operation of the motor, which is also an effective way to improve the efficiency of the motor.

When the fan of the motor is reduced, the mechanical loss will also be reduced accordingly, but whether it can meet the heat dissipation requirements of the motor is very critical, which will involve the compliance of an air path and heat dissipation components, such as the chassis, end caps and other components In addition, measures such as increasing the effective material may be adopted, that is, the iron length of the motor and the corresponding conductor material may be increased on the original basis. These comprehensive measures will better ensure the temperature rise level of the motor, thereby improving the efficiency of the motor, which is one of the characteristics of the low temperature rise of the high-efficiency motor.

In addition to material factors, high-efficiency motors are very important for the dimensional control of machined parts, ensuring the coaxiality requirements during motor operation to the greatest extent, and can effectively reduce the vibration caused by unilateral magnetic pull during motor operation; The size control and shape optimization of the motor winding end can effectively improve the air path of the motor, which is also the control difficulty in the motor manufacturing process.

Under the conditions of the same scheme and the same material consumption, some can achieve lower motor efficiency at high temperature, while others can only be inferior products, which is reflected in the differences in motor manufacturing processes. Therefore, a good design must be guaranteed by a good process .

XINDA

XINDA