What is a DC brushed motor? What are its internal structures

This section discusses DC brushed motors. As mentioned in the previous section, when using a motor to drive a mechanism, we need continuous power and want the mechanism to keep moving. The motor used in this case is a drive motor, which moves as soon as it is powered on; it is also known as a general-purpose motor.

DC brushed motor:

So, a DC brushed motor is a type of drive motor. Because it has brushes, it's also called a DC carbon brush motor, similar to the motor in the four-wheel drive cars we played with as kids.

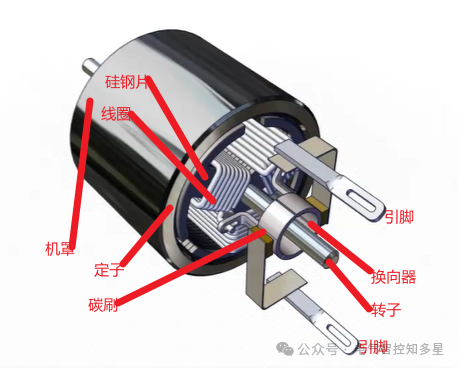

Here's a diagram of its internal structure. The top and bottom pins are used for energizing, and the pins connect to the carbon brushes. The three copper plates that the carbon brushes contact are the commutator or rectifier. The middle part is the rotor, and above the rotor are coils composed of many coils and silicon steel sheets. The outermost shell is the housing, and inside the housing is the stator.

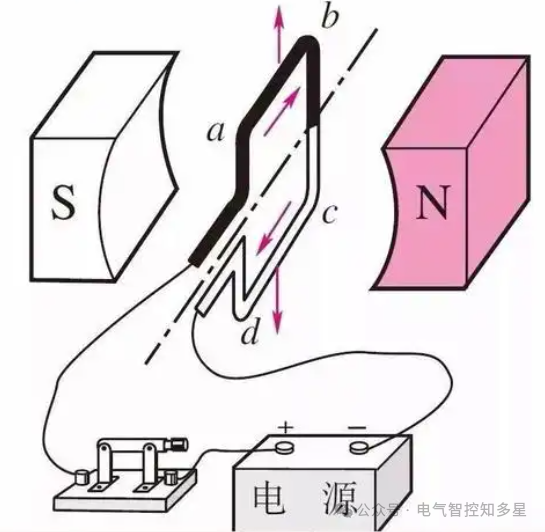

The principle of motor rotation:

It's worth noting that the stator is a permanent magnet, meaning it has its own magnetic field. If the coil above the rotor is energized, it will also generate a magnetic field. Since the stator itself is both a permanent magnet and has a magnetic field, the interaction between these two magnetic fields, based on the principle of like poles repelling and unlike poles attracting, can drive the rotor to rotate.

DC brushed motor pinout:

The two pins are for power connection; one is connected to 12V/24V/36V/48V, and the other is connected to 0V, creating a voltage difference.

Advantages and disadvantages of DC brushed motors :

Advantages: Carbon brushes are mostly made of graphite because they are wear-resistant, have good electrical conductivity, are self-lubricating, and have a simple and inexpensive structure.

DC brushed motor voltage :

XINDA

XINDA