What should I do if I find high-frequency electromagnetic sound during the use of the motor?

Electromagnetic sound is a kind of noise that often occurs in motor products. High-frequency electromagnetic sound is sharp and relatively harsh, similar to a whistle; low-frequency electromagnetic sound is relatively dull, similar to the sound of a tractor. High-frequency electromagnetic sound is often a congenital defect of the motor, which is difficult to solve during later use.

In most cases, the electromagnetic noise, mechanical noise and ventilation noise of the motor exist at the same time, but their respective weights are different. Sometimes it is not easy to distinguish them, especially the high-frequency electromagnetic and ventilation noise, which sometimes sound very similar. Here I will share with you a simple method.

When the motor is operating normally, block the air outlet of the motor. If the sound drops significantly, it means that the ventilation noise is quite obvious. Otherwise, it means that the noise is not caused by ventilation.

Use power-off method to identify: when the power is cut off, the original screaming sound of the motor basically disappears, then it is determined to be electromagnetic noise, otherwise, the noise will not disappear due to power cut-off.

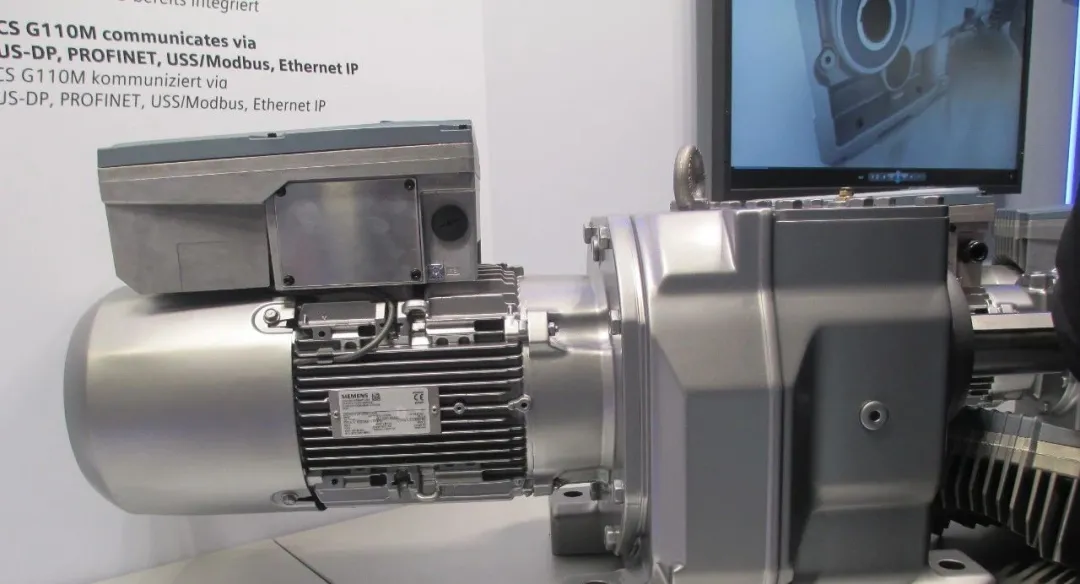

High-frequency electromagnetic noise is related to the voltage and frequency of the power supply. The higher the voltage, the more obvious the noise. For variable frequency motors, obvious electromagnetic noise may appear in a certain frequency band, while there is basically no electromagnetic noise when working in other frequency bands. Some motors have electromagnetic noise during the starting stage of the motor, and the electromagnetic noise is not obvious during normal operation.

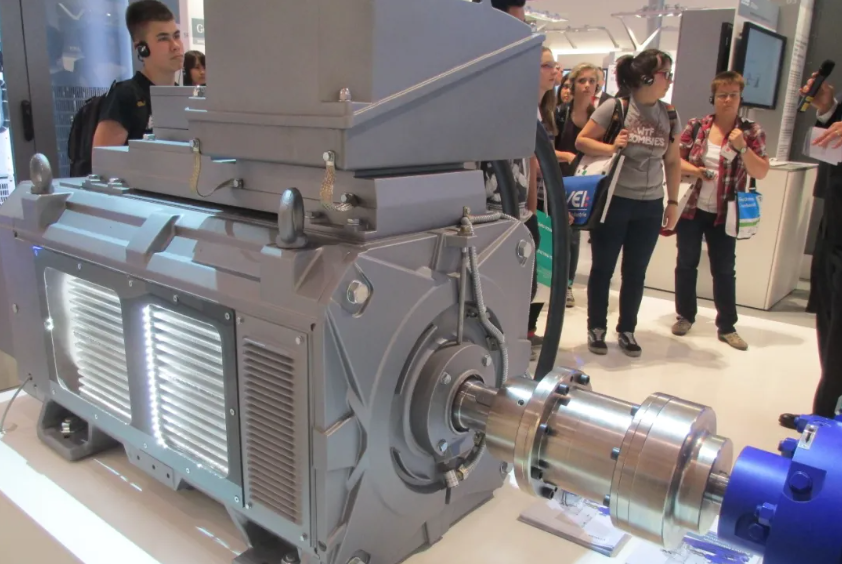

From the analysis of the mechanism of electromagnetic noise generation, low-frequency electromagnetic sound is more caused by defects in the later manufacturing process, such as uneven air gap between the stator and the rotor, loose stator winding and iron core, rotor imbalance and other factors; while high-frequency electromagnetic sound requires more adjustments and improvements in the design process, such as reasonable slot matching, the use of low-harmonic windings, rotor skew slots, the use of closed slots and other specific measures for control.

For motors, unstable power supply may also excite stator vibration and generate noise. The main characteristics of electromagnetic noise are related to factors such as alternating electromagnetic field characteristics, forced vibration components and the size and shape of the space.

XINDA

XINDA