Technical advantages of vertical outer rotor permanent magnet variable speed direct drive motor

The Carbon Neutrality Research Center of the Central Research Institute of State Power Investment Corporation took the lead and jointly developed the first vertical outer rotor permanent magnet variable speed direct drive motor for the air-cooled island of a thermal power plant in China with Shengyilun Power Investment Technology Co., Ltd. and China Shipbuilding 712 Research Institute . The motor has the characteristics of low noise, low loss, simple structure and low maintenance cost, which can effectively reduce maintenance and maintenance costs while achieving high efficiency and energy saving.

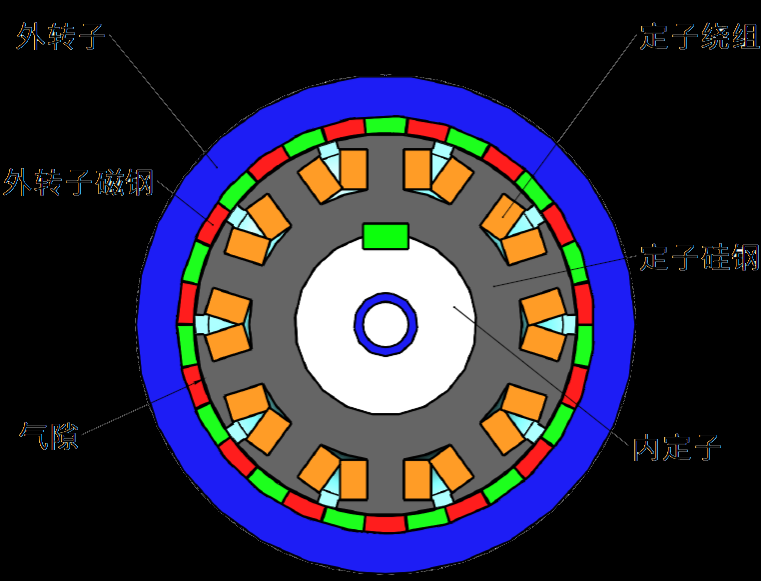

Vertical outer rotor permanent magnet variable speed direct drive motor

Technical principle

Compared with the structure of traditional asynchronous motors , the rotating body of the vertical outer rotor permanent magnet variable speed direct drive motor specially used for the air-cooled island is located in the outer shell of the fuselage, and multiple pairs of permanent magnets are embedded inside the rotating body. Low-speed and high-torque direct drive is achieved by increasing the number of magnetic pole pairs. The drive windings are distributed inside the fuselage, and speed change is achieved through variable frequency vector control.

Schematic diagram of the internal structure of the motor

Technological innovation

1. Simple structure. Compared with the original complex structure of asynchronous motor + coupling + gear box + load, the vertical outer rotor permanent magnet variable speed direct drive motor is directly connected to the load through the outer rotor, which increases the moment of inertia of the outer rotor , can significantly reduce the loss of power transmission efficiency and improve the utilization rate of electric energy.

2. Energy saving and consumption reduction. The permanent magnet magnetic field is used to realize the transmission of electrical energy and mechanical energy, which improves the power factor and efficiency. In addition, the outer rotor is directly connected to the load, which reduces the loss of multi-stage transmission of the system and greatly reduces energy consumption.

3. Low maintenance cost. The direct drive motor is directly connected to the load, without any mechanical gearbox or accessories in between, which reduces the failure rate of the overall system and also reduces a lot of maintenance cost and time.

4. Environmentally friendly and low noise. The air-cooled island cooling system composed of an outer rotor permanent magnet direct-drive motor avoids the oil cooling system and reduces the excitation noise.

Product Specifications

|

Parameters of permanent magnet direct drive motor for air cooling island of thermal power plant |

|

| power | 110kW |

|

Rated speed |

81.2r/min |

|

efficiency |

95.3% |

|

Power Factor |

0.986 |

|

Forward speed control range |

30%~110% |

|

Reverse speed control range |

0~30% |

|

Protection level |

IP45 |

|

gross weight |

2600kg |

Product Advantages

The motor drive system has the advantages of large moment of inertia, material saving, good heat dissipation, environmental protection, low failure rate, and reduced daily maintenance workload. Compared with asynchronous motors, low-speed, high-torque permanent magnet direct-drive motors also have the advantages of flexible load driving mode, excellent starting performance, and easy speed regulation, while reducing the volume of air-cooled island drive units.

Economic Benefits

A single cooling system consisting of a vertical outer rotor permanent magnet variable speed direct drive motor dedicated to the air cooling island can save 39,900 yuan in electricity per year. A 2×600,000 kW thermal power plant requires 112 air cooling island cooling units. If all of them replace the original system, it can save 4.4688 million yuan in electricity bills and 1.1 million yuan in maintenance costs per year, which can save nearly 5 million yuan in total per year.

Application Scenario

The vertical outer rotor permanent magnet variable speed direct drive motor can replace the air-cooled drive unit of the air-cooled island of a thermal power plant. By replacing the output type of the original motor plus a mechanical gearbox through the outer rotor direct drive, it can be widely used in outer rotor fans , various transmission motors, and ship electric propulsion.

XINDA

XINDA