How to reduce motor iron loss

To analyze the problem, we first need to know some basic theories, which will help us understand. First, we need to know two concepts. One is alternating magnetization, which is simply what happens in the iron core of the transformer and the stator or rotor teeth of the motor; the other is rotating magnetization, which is produced by the stator or rotor yoke of the motor. There are many articles that start from two points and calculate the iron loss of the motor according to different characteristics in the above solution method. Experiments show that the following phenomena exist in silicon steel sheets under two types of magnetization:

When the magnetic flux density is below 1.7 Tesla, the hysteresis loss caused by rotating magnetization is greater than that caused by alternating magnetization; when it is higher than 1.7 Tesla, the opposite is true. The magnetic flux density of the motor yoke is generally between 1.0 and 1.5 Tesla, and the corresponding rotating magnetization hysteresis loss is about 45 to 65% greater than the alternating magnetization hysteresis loss.

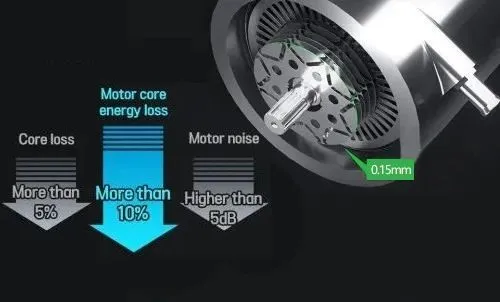

Of course, the above conclusions are also taken, and I have not actually verified them. In addition, when the magnetic field in the iron core changes, a current will be induced in it, which is called eddy current, and the loss caused by it is called eddy current loss . In order to reduce eddy current loss, the motor core is usually not made into a whole piece, but is stacked axially by mutually insulated steel sheets to hinder the flow of eddy current . The specific iron loss calculation formula will not be cumbersome here. If you search Baidu for the basic formula and meaning of iron loss calculation, it will be very clear. The following analyzes several key points that affect our iron loss, so that everyone can forward or reverse the problem in actual engineering applications.

After talking about the above, let's talk about why the manufacturing of punching sheets affects iron loss? The punching process characteristics are mainly determined according to the different shapes of punching machines, according to the requirements of different types of holes and slots, and the corresponding shear mode and stress level are determined to ensure the conditions of the shallow stress area outside the lamination. Because of the relationship between depth and shape, it is often affected by sharp angles, so that high stress levels will cause great iron loss in the shallow stress area , especially in the part with relatively long shear edges within the lamination range. Specifically, it mainly appears in the tooth groove area, so in the actual research process, it often becomes the focus of research. Low-loss silicon steel sheets are often determined by larger grain sizes. The impact will cause synthetic burrs and tear shear at the bottom of the punching sheet, and the angle of the impact will have a significant impact on the burr size and deformation area. If a high stress area extends along the edge deformation zone to the inside of the material, then the grain structure in these areas is bound to change accordingly, it will be distorted or broken, and an extremely elongated boundary will be produced along the tearing direction. At this time, the grain boundary density of the stress area in the shear direction is bound to increase, which will lead to a corresponding increase in the iron loss inside the area. Therefore, the material in the stress zone can be considered as a high-loss material that falls on the ordinary lamination along the impact edge. In this way, the actual constants of the edge material can be determined, and the iron loss model can be used to further determine the actual losses of the impact edge.

Effect of annealing process on iron loss

The influencing factors of iron loss mainly exist in silicon steel sheets, and mechanical and thermal stresses will affect silicon steel sheets as their actual characteristics change. Additional mechanical stress will cause changes in iron loss. At the same time, the continuous increase in the internal temperature of the motor will also promote the emergence of iron loss problems. Taking effective annealing measures to remove additional mechanical stress will have a favorable effect on reducing the iron loss in the motor.

Reasons for high losses in the manufacturing process

As the main magnetic conductive material of the motor, the performance compliance of silicon steel sheet has a great impact on the performance of the motor. The main thing is to ensure that the grade of silicon steel sheet meets the design requirements. In addition, the material performance of silicon steel sheets of the same grade from different manufacturers is somewhat different. When selecting materials, you should try your best to select materials from good silicon steel manufacturers. The following are some key factors that actually affect iron loss.

⏩The silicon steel sheet has not been insulated or has not been properly insulated. This type of problem can be found during the inspection of the silicon steel sheet, but not all motor manufacturers have this inspection item, and this problem is often not well identified by motor manufacturers.

⏩ Damage to insulation between sheets or short circuit between sheets. This type of problem occurs during the manufacturing process of the core. If the pressure during the lamination of the core is too high, the insulation between sheets will be damaged; or the burrs after the punching are too large, and the burrs are removed by grinding, resulting in serious damage to the insulation on the surface of the punching sheet; or the slots are not smooth after the lamination of the core, and the filing method is used; or the stator inner bore is not smooth, the stator inner bore and the machine base stop are not concentric, etc., and the turning method is used to correct it. These common usages in the motor production and processing process actually have a great impact on the performance of the motor, especially the iron loss.

⏩When the winding is removed by burning or heating with electricity, the core will overheat, causing the magnetic conductivity to decrease and the insulation between the sheets to be damaged. This problem mainly occurs during the repair of windings and motors during the production process.

⏩Stacking welding and other processes will also damage the insulation between the stacked sheets and increase eddy current losses.

⏩The iron weight is insufficient and the sheets are not compacted. The final result is that the iron core weight is insufficient, which will directly lead to excessive current and excessive iron loss.

⏩ Silicon steel sheet is painted too thickly, resulting in oversaturation of magnetic circuit. At this time, the relationship curve between no-load current and voltage is severely bent. This is also a key factor in the production and processing of silicon steel sheets.

⏩The production and processing of the iron core will cause the grain orientation of the silicon steel sheet punching and shearing surface to be destroyed, resulting in an increase in iron loss under the same magnetic induction; for variable frequency motors, there is also the additional iron loss caused by harmonics; this is a factor that should be comprehensively considered in the design process.

In addition to the above factors, the design value of motor iron loss should be based on the actual production and processing of the core, and try to make the theoretical value match the actual value. The characteristic curve provided by the general material supplier is measured according to the Epstein circle method, but the magnetization direction of different parts in the motor is different. This special rotational iron loss cannot be taken into account at present. This will lead to inconsistency between the calculated value and the measured value to varying degrees.

There are many ways to reduce iron loss in engineering, and the most important thing is to prescribe the right medicine for the disease. Of course, it is not only a problem of iron loss, but other losses are the same. The most fundamental way is to know the reason for the high iron loss, whether it is due to high magnetic density, high frequency, or excessive local saturation, etc. Of course, according to the normal way, on the one hand, it is necessary to try to get as close to reality as possible from the simulation side, and on the other hand, the process matching technology reduces the additional iron loss. The most common way is to increase the replacement of good silicon steel sheets. If the cost is not taken into account, imported super silicon steel can be selected. Of course, with the development of domestic new energy drive technology, it has also led to better development of upstream and downstream. Domestic steel mills are also launching special silicon steel products. The spectrum has a better product classification for different application scenarios. Here are a few more direct methods:

⏩ Optimize magnetic circuit

Optimizing the magnetic circuit, or more precisely, optimizing the sinusoidality of the magnetic field. This is critical, and it is not only necessary for fixed-frequency induction motors . Variable-frequency induction motors and synchronous motors are both crucial. When I was working in the textile machinery industry, I made two motors with different performances in order to reduce costs. Of course, the most important thing was whether there was a skew pole, which led to inconsistent sinusoidality of the air gap magnetic field. Because they work at high speeds, iron loss accounts for a large proportion, so the loss of the two motors is very different. Finally, after a series of reverse calculations, the iron loss of the motor under the control algorithm differed by more than 2 times. Here I would also like to remind everyone that when making variable-frequency speed-regulating motors, you must couple the control algorithm to do it.

⏩ Reduce magnetic density

Increasing the length of the iron core or increasing the magnetic conductivity area of the magnetic circuit can reduce the magnetic flux density, but the amount of iron used in the motor will increase accordingly;

⏩Reduce the thickness of the iron core to reduce the loss of induction current

For example, using cold-rolled silicon steel sheets instead of hot-rolled silicon steel sheets can reduce the thickness of the silicon steel sheets, but thin iron sheets will increase the number of iron sheets and the manufacturing cost of the motor;

⏩ Use cold-rolled silicon steel sheets with good magnetic conductivity to reduce hysteresis loss;

⏩ Using high-performance iron core insulation coating;

⏩ Heat treatment and manufacturing technology

The residual stress after iron core processing will seriously affect the loss of the motor. When processing silicon steel sheets, the cutting direction and punching shear stress have a greater impact on the core loss. Cutting along the rolling direction of silicon steel sheets and heat treating silicon steel punching sheets can reduce the loss by 10% to 20%.

XINDA

XINDA