Running and speed control principle of DC motor

A DC motor refers to a rotating electrical machine that can convert DC electrical energy into mechanical energy (DC motor) or mechanical energy into DC electrical energy (DC generator). It is a motor that can realize mutual conversion of DC electrical energy and mechanical energy.

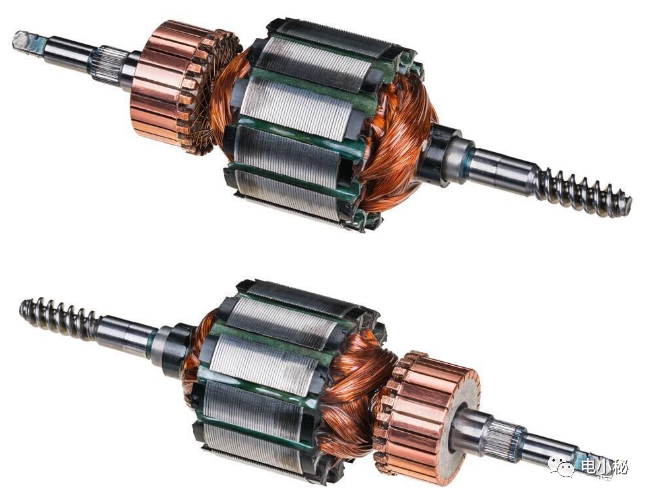

How DC motors work

1. The DC power supply current flows along the positive pole of the power supply to the brush on the left. The brush and the commutator rub against each other, and the current passes through the commutator on the left (also called a commutator. This motor has two commutators on the left and right). It flows into the coil, flows out from the right side of the coil, flows back to the negative pole of the power supply through the right commutator segment and the right brush, forming a closed loop.

2. Since the coil is in the magnetic field of the main magnetic poles (N and S in the figure), the coil will be affected by the electromagnetic force. The two sides of the coil have different directions of current (the current on the left flows inward, and the current on the right flows outward. ), so the two coil sides are subjected to electromagnetic forces of the same magnitude and opposite directions. These two electromagnetic forces just form electromagnetic torque. Under the pull of the electromagnetic torque, the coil begins to rotate. The coil in the DC motor is embedded in the rotor slot, and the motor starts to rotate.

3. The left and right commutator segments rotate with the rotating shaft, while the brushes are fixed. After one rotation, the right coil goes to the left, and the left coil goes to the right. However, due to the existence of the commutator segments, the coil is now in the left coil. The direction of the current flows in the same direction as the original coil on the left, so the direction of the electromagnetic force it receives does not change, and the same applies to the right side. Therefore, from a spatial perspective, the direction of the electromagnetic force received by the coil at the same position remains unchanged, which ensures the cyclic rotation of the motor.

4. But for a coil, because the magnetic field is different when the coil rotates to different positions, the electromagnetic force experienced by the coil is also constantly changing, so the coil rotates unstable, sometimes fast and sometimes slow. Therefore, you can install several more coils to ensure uniform and stable force on the coils.

DC motor characteristics

1. High operating efficiency. Due to the small resistance of the motor when working under no load, the operating efficiency is high and the performance is relatively stable, which can ensure high efficiency and long-term operation;

2. The starting current is very small. When the rotor is idling, the magnetic field has been formed on the rotor. It only operates normally without starting current;

3. Easy to control, it can be controlled by frequency converter or control panel according to the initial situation, enjoying the stability of constant control.

DC motor advantages

1. Large driving power: DC motors can rotate relatively large mechanical loads. They can provide greater power output and better impact resistance than AC motors of the same capacity;

2. Stable and reliable work: Stable operation, especially suitable for long-term continuous work, and work efficiency has nothing to do with the degree of moisture;

3. Controllable control: Various circuits such as inverters, control panels, and slippers can be used to control a stable speed, and constant speed control can be achieved. Compared with other motors, it is more stable and reliable.

Disadvantages of DC motors

1. Limited air cooling: Due to the topological structure of the DC motor, its air cooling capacity is limited, so it will generate more heat during work, affecting stable operation.

2. Unable to achieve braking output: Due to its topological structure, when running at high speed, braking output cannot be achieved, which will affect stable operation.

3. Affected by power supply: Due to high power requirements, power outages and power switching will affect the operating performance of the DC motor.

4. Interference by the magnetic field: The magnetic field drift of the meat layer caused by changes in the internal magnetic field of the machine will affect the torque speed regulation and noise intensity.

DC motor control principle

(1) Trial and error method

The trial and error method is to manually select the PID parameters to make the control system response meet the predetermined requirements. This method is both simple and complex. To put it simply, if you have experience and luck, you may achieve the goal quickly in SIMULINK. What is difficult to say is that in actual on-site combat, a lot of time and energy may have been spent adjusting the three parameters, but the task was not completed.

(2) Critical proportion method

The critical proportion method is to adjust the proportion to make the system oscillate with constant amplitude only under the action of P, and then calculate the PID value effect according to the formula. The left half is the constant amplitude oscillation of the system, and the right half is the control effect. The curve effect controlled by the PID critical proportion method simulated by MATLAB.

(3) Decay curve method

The attenuation curve method is to adjust the proportion so that the system response curve attenuates at a ratio of 4:1 or 10:1 only under the action of P, and then calculate the PID value effect according to the formula. The left half is the system attenuation curve, and the right half is the control effect. . The curve effect is controlled by the PID decay curve method simulated by MATLAB.

(4) Reaction curve method

The reaction curve method is to add a step signal in the open loop state, and then use a first-order pure hysteresis system to approximate the original system, and then calculate the PID value effect according to the ZN or CC formula. The left half is the system response curve, and the right half is It is the control effect. A third-order system, the relevant parameters obtained by the critical proportionality method. The figure below is the curve effect controlled by the PID response curve method simulated by MATLAB.

Three methods of DC motor speed regulation

1. Adjust the armature supply voltage U

Changing the armature voltage is mainly to reduce the armature voltage downward from the rated voltage and change the speed downward from the rated speed of the motor, which is a constant torque speed regulation method. This method is best for systems that require stepless and smooth speed regulation within a certain range. The time constant encountered by armature current changes is small and it can respond quickly, but it requires a large-capacity adjustable DC power supply.

2. Change the main magnetic flux φ of the motor

Changing the magnetic flux can achieve stepless smooth speed regulation, but it can only weaken the magnetic flux and adjust the speed upward from the rated speed of the motor, which is a constant power speed regulation method. The time constant encountered when the armature current changes is much larger, and the response speed is slower. However, the required power supply capacity is small.

3. Change the armature circuit resistance R

The method of adjusting the speed by adding a series resistor outside the motor armature circuit has simple equipment and easy operation. However, it can only have step speed regulation, which has poor smoothness and soft mechanical properties; it consumes a lot of electric energy on the speed regulation resistor. Changing the resistance to adjust speed has many disadvantages and is rarely used at present.

There are specifically the following 7 methods for motor speed regulation:

1. Pole-changing logarithmic speed regulation method

This method of speed regulation achieves the purpose of speed regulation by changing the stator winding wiring method and thereby changing the number of stator pole pairs of the cage motor. Its characteristics are as follows.

① The mechanical properties are hard and the stability is good.

② No slip loss and high efficiency.

③ Simple wiring method, convenient control and low price.

④ Stepped speed regulation can be achieved, but the step difference is large, so smooth speed regulation cannot be obtained.

⑤ It can be used in conjunction with voltage regulation speed regulation and electromagnetic slip clutch to obtain smooth speed regulation characteristics with higher efficiency.

The pole-changing logarithmic speed regulation method is suitable for production machinery that does not require stepless speed regulation, such as metal cutting machine tools, elevators, hoisting equipment, fans, pumps, etc.

2. Frequency conversion speed regulation method

Variable frequency speed regulation refers to a speed regulation method that changes the frequency of the motor's working power supply, thereby changing its synchronous speed. The main equipment of the variable frequency speed control system is the frequency converter that provides variable frequency power. The frequency converter can be divided into two categories: "AC-DC-AC" frequency converter and "AC-AC" frequency converter. At present, most of the domestic use "AC-DC-AC" "Inverter, its characteristics are as follows.

① There is no additional power loss during the speed adjustment process, and the efficiency is high.

② It has a wide range of applications and can be used in cage-type asynchronous motors.

③ Large speed range, hard mechanical properties, and high speed accuracy.

④ The technical design is complex, the cost is high, and maintenance and repair are difficult.

The variable frequency speed regulation method is suitable for occasions with higher precision requirements and better speed regulation performance.

3. Cascade speed regulation method

Cascade speed regulation refers to inserting an adjustable additional electromotive force into the rotor circuit of a wound motor to change the slip of the motor, thereby achieving the purpose of speed regulation. The additional electromotive force inserted in series absorbs most of the slip power of the motor, and then the device that generates the additional electromotive force is used to convert the absorbed slip power into energy for utilization or return to the grid. According to the different ways of absorbing and utilizing slip power, cascade speed regulation can be divided into three types: thyristor cascade speed regulation, mechanical cascade speed regulation and motor cascade speed regulation. Thyristor cascade speed regulation is mostly used in engineering. Its characteristics are as follows.

① The slip loss during the speed regulation process can be fed back to the production machinery or power grid with high efficiency.

② The speed regulation range changes in direct proportion to the device capacity, requiring low investment. It is suitable for production machinery with a speed regulation range of 70% to 90% of the rated speed.

③ When the speed regulating device fails, the system can switch to full-speed operation without affecting production.

④ The power factor of thyristor cascade speed regulation is low and the harmonic influence is large.

The cascade speed regulation method is suitable for fans, water pumps and rolling mills, mine hoists and extruders.

4.Series resistor speed regulation method

The series resistor speed regulation method is only applicable to wound rotor asynchronous motors. Adding additional resistors in series to the motor rotor increases the slip rate, allowing it to run at a lower speed. The greater the series resistance, the lower the motor speed. The lower. This method has simple equipment and convenient control, but the slip power is consumed in the resistor in the form of heat. It belongs to step speed regulation and has soft mechanical characteristics.

5. Stator voltage and speed regulation method

According to the mechanical characteristics of the motor, when the stator voltage of the motor is changed, a different set of mechanical characteristic curves can be obtained, thereby obtaining different speeds of the motor under various stable working conditions. Since the torque of the motor is proportional to the square of the voltage, the maximum torque of the motor drops a lot during the voltage drop, and its speed regulation range is small, making it difficult to apply to general cage motors. In order to expand the speed regulation range, the stator voltage regulation and speed regulation should use a cage motor with a large rotor resistance, such as a torque motor specially used for voltage regulation and speed regulation, or a frequency-sensitive resistor in series with the wound rotor motor; in addition, in order to ensure For a larger stable operating range, feedback control should be used when the speed adjustment range is above 2:1 to achieve the purpose of automatically adjusting the speed.

The main device for stator voltage and speed regulation is a power supply that can provide voltage changes. Currently, commonly used voltage regulation methods include autotransformers, series saturated reactors and thyristor voltage regulation, among which the thyristor voltage regulation method has the best effect. The characteristics of the stator voltage and speed regulation method are as follows.

① Advantages: The voltage and speed regulation circuit is simple and easy to realize automatic control.

② Disadvantages: The slip power during the voltage regulation process is consumed in the rotor resistance in the form of heat, and the efficiency is low.

Stator voltage regulation and speed regulation are generally suitable for production machinery with a capacity below 100kW.

6. Electromagnetic speed regulating motor speed regulation method

The electromagnetic speed-regulated asynchronous motor is composed of three parts: an ordinary cage asynchronous motor, an electromagnetic slip clutch and an electrical control device. The asynchronous motor is used as the prime mover. When it rotates, it drives the armature of the clutch to rotate together. The electrical control device provides the excitation current of the slip clutch excitation coil. The electromagnetic slip clutch consists of three parts: armature, magnetic pole and excitation coil. The armature is a cylindrical structure made of cast steel, which is connected to the rotating shaft of the cage asynchronous motor, commonly known as the active part; the magnetic poles are made into a claw-shaped structure and mounted on the load shaft, commonly known as the driven part. There is no mechanical connection between the active part and the driven part. When the excitation coil passes current, a magnetic field is generated, and the claw-shaped structure forms many pairs of magnetic poles. At this time, if the armature is dragged and rotated by a cage-type asynchronous motor, the relative motion between the armature and the magnetic poles will cause the armature to induce eddy currents. This eddy current interacts with the magnetic flux to generate torque, driving the rotor with the magnetic poles in the same direction. It rotates, but its speed is always lower than the armature speed. This is a slip speed regulation method. Changing the DC excitation current of the slip clutch can change the output torque and speed of the clutch. The speed regulating characteristics of electromagnetic speed regulating motor are as follows.

① The device structure and control circuit are simple, reliable in operation and easy to maintain.

② The speed regulation is smooth and stepless speed regulation can be achieved.

③ No harmonic impact on the power grid.

④ The speed distortion is large and the efficiency is low.

The electromagnetic speed-regulating motor speed regulation method is suitable for production machinery with small and medium power that requires smooth start and low-speed operation.

7. Hydraulic coupler speed adjustment method

Hydraulic coupling is a hydraulic transmission device, also called hydraulic coupling, which mainly consists of three parts: housing, pump wheel and turbine. The pump wheel and turbine are collectively called the working wheel and are placed in a sealed housing. A certain amount of working fluid is filled into the shell. When the pump wheel rotates under the driving of the prime mover, the pump wheel blades push the hydraulic oil in it to rotate. Under the action of centrifugal force, the hydraulic oil enters the turbine along the outer ring of the pump wheel, and in the same direction Torque is applied to the turbine blades to drive the production machinery. The power transmission capacity of the hydraulic coupling is proportional to the relative fluid filling volume in the shell. As the hydraulic oil volume increases, the output torque increases, and the turbine speed increases accordingly, thereby achieving the purpose of adjusting the speed. In engineering practice, as long as the liquid filling rate is changed, the turbine speed of the coupler can be changed to achieve stepless speed regulation. Its characteristics are as follows.

① The power adaptability range is large and can meet different power needs from tens of kilowatts to several megawatts.

② Simple structure, no electrical connections, reliable operation, low environmental requirements, easy maintenance and low cost.

③ The size is small and the energy volume change range is relatively large.

④ Convenient control and adjustment, easy to realize automatic control.

⑤ The speed regulation depends on the amount of oil and load, and the speed regulation accuracy is low. When the load changes, the speed changes accordingly.

XINDA

XINDA