HOW TO CHOOSE THE IDEAL GEARBOX MOTOR SOLUTION FOR AN ENGINEERING PROJECT?

MOTOR CUSTOMIZATION | HOW TO CHOOSE THE IDEAL GEARBOX MOTOR SOLUTION FOR AN ENGINEERING PROJECT?

What is a gearbox motor?

A gear motor is a special type of electromechanical device that combines an electric motor with a gearbox designed to produce high torque while maintaining low horsepower output. Gear motors have a wide range of applications. Choosing the right gear motor for your project is no easy task. Sometimes, looking at what products your competitors are using may not be helpful to you, and you may end up wasting valuable time, energy, and budget. It's time to rethink this approach.

How to choose the ideal gearbox solution for your engineering project?

Basically, electric motors and gearboxes can be mixed as needed, and the optimal solution is adapted to the product application, but ultimately the gear motor as a whole is the primary driver. There are many types of motor and gearbox combinations on the market, for example, worm, spur and planetary gearboxes can be combined with universal, permanent magnet DC or brushless DC motors. Although many different motor and gearbox combinations can be used for your application, some combinations will be more efficient and cost-effective than others. Understanding gear transmission and reducer applications and obtaining accurate ratings and characteristics are basic knowledge for integrating gear reducers into systems.

Just four simple steps guide designers in selecting the best electric motor and gearbox for a specific application:

1. Determine application requirements, see Application Checklist

2. Select the motor type, please refer to the " Motor Selection Guide ".

3. Select matching speed and torque output for the gear motor, please refer to " Gear Motor Performance Curve "

4. Ensure application yield strength and torque meet application requirements.

|

Input power |

Voltage

Frequency (Hz) Maximum current (in amps) Control type (if applicable) |

|

Application Environment |

Protection IP level ambient temperature Application temperature

|

|

Gearbox Motor Specifications |

Dimensions and weight

Life/Maintenance noise |

|

Gearbox motor performance |

Speed/Torque Starting torque/stall torque Duty cycle ("on" and "off" time) |

Application Checklist - Use this checklist to help develop specific requirements to ensure the gear motor supplier has the critical information necessary to achieve the best match between the gear motor and the application.

As the motor or gearbox selection process begins, it is important that the design engineer gathers relevant technical and commercial requirements during the design process. The design input information gathered is used in the selection process and determines the ideal motor for the application. Failure to gather the right input can lead designers down an unintentional path. Therefore, it is helpful to use an "Application Checklist" when sizing your motor. These parameters, along with some project-specific requirements, will be essential when navigating the selection process.

Next, the design engineer must consider which type of motor technology is best suited for the intended application. Use the "Motor Selection Guide" as a reference for decision-making. This guide details three common motor types and provides general information to consider when selecting each motor. Since each application has its unique characteristics, it is important to determine which parameter (i.e. power, efficiency, durability, starting torque or noise level, etc.) is most important for the application under consideration. During the motor selection process, by observing the required speed and torque application, it should be obvious to the designer if the selected motor requires a gearbox to meet the necessary requirements. If the application requires a gear motor, another level of complexity is added and several additional criteria need to be evaluated.

|

|

|

|

|

|

Voltage |

DC |

comminicate |

AC or DC |

| Speed(rpm) | 1000-5000 | 1600-3400 | 1000-5000 |

| power | medium | Lower than average | high |

| efficiency | 60-70% | 40-80% | 65-80% |

| life | medium | very high | very high |

| maintain | medium | very low | very low |

| noise | medium | Quiet | very quiet |

| speed regulation | generally | good | excellent |

| Starting torque | very high | Lower than average | very high |

Motor Selection Guide - provides a comparison of commonly used parameters in the motor selection process

When design engineers consider selecting an integral gearbox motor, a quick way to make a selection is to look at a pre-designed, similar gearbox motor. This is an effective means of finding the most compatible gear motor as it reduces design time and project risk. When choosing a pre-engineered solution, the manufacturer has done a lot of startup work to ensure that the motor and gearbox combination will work properly. Since performance feasibility studies and testing have been conducted by the manufacturer, gear motor failures caused by incorrect calculations or improper component matching will be minimized. Due to the complexity of selecting motors and gearboxes, Power Motor focuses on finding the ultimate gear motor solution that meets or exceeds customer needs.

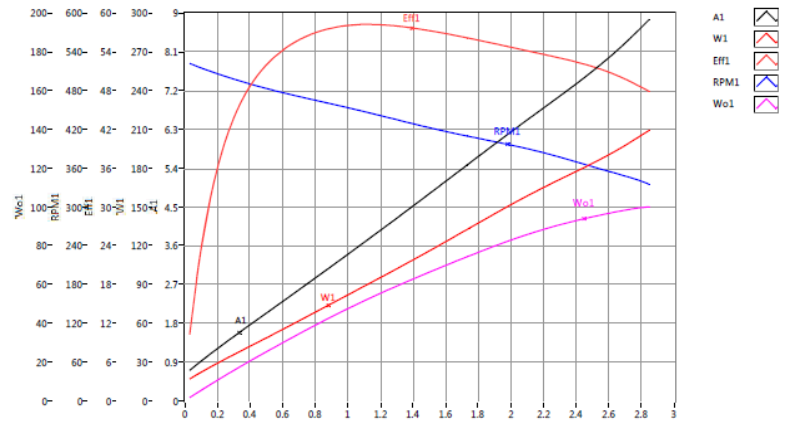

Again reviewing the gear motor performance data collected from the Application Checklist, the speed and torque required for the application are critical in selecting a gear motor combination. Designers can use speed and torque measurements to select performance curves that match application needs. The "Gear Motor Performance Curve" combines the performance of the motor and gearbox by showing speed, torque and efficiency.

Finally, after selecting a few performance curves that meet the needs of the application, it is important to examine the design limitations. Find the following information in the performance calculation and use it to determine if the selected gear motor will cause any problems in the application.

-

Thermal properties

-

Full load gearbox speed

-

Gearbox input speed

-

Gearbox Yield Strength

-

Considerations for Intermittent Duties

|

High Torque motor for coffee machine Model:PGM-W63 Voltage: 24V DC Power:100W Efficiency: 60% Torque: 1N.m Speed:457 rpm |

|

|

|

Gear Motor Performance Curves – Speed/torque and efficiency/performance curves for permanent magnet DC gear motors.

For more information or help selecting the ideal gear motor, please contact our sales engineers for any off-the-shelf products or custom engineering services.

XINDA

XINDA