What should I do if the stator winding of the brushless motor is not neatly arranged?

Date:2023-11-27 Author:Shandong Xinda Motor Co., Ltd.

What should I do if the stator winding of the brushless motor is not neatly arranged? What are the main reasons?

During the winding and arranging process of the brushless motor stator, sometimes due to human operation or machine problems, some minor problems may occur, such as uneven and loose winding and arranging, etc. Then the brushless motor stator winding What are the main causes of uneven cable arrangement and how to solve it?

1. Machine configuration: Improper configuration of the winding machine and failure to configure it as required may result in uneven winding.

2. Machine design: If the machine structure design is unreasonable, it may also lead to uneven wiring. The structure should be as simple as possible, adaptable to most similar products, and have strong controllability.

3. Accuracy of enameled wire: The selection of enameled wire is also very important. If the selection is unreasonable, it is likely to cause overlap and jumpers.

4. Stator skeleton structure and mold accuracy: Unreasonable stator skeleton structure or insufficient mold accuracy may also lead to uneven wiring.

5. Controller accuracy: The control accuracy itself cannot meet the requirements, so no matter how good the debugging technology is, it may not be able to adjust to the appropriate accuracy.

6. The tensioner tension is not adjusted properly: the tension cannot be too large or too small, otherwise it will cause the winding and wiring to be uneven. It needs to be set according to the table requirements.

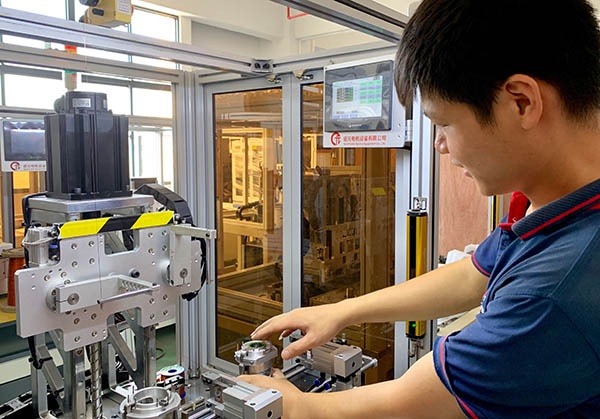

stator winding and wiring

To solve the problem of uneven stator winding and wiring, the above reasons must be analyzed and corresponding measures must be taken, such as adjusting the configuration of the winding machine, structural design, selection of enameled wire, stator skeleton structure and accuracy, controller accuracy, mold accuracy, etc. At the same time, attention should also be paid to issues such as tensioner control, the working status of the wiring device and mold device, and the accuracy of the PLC servo drive controller.

XINDA

XINDA