Damage to motor caused by inverter

Date:2023-11-21 Author:Shandong Xinda Motor Co., Ltd.

Although the phenomenon of motor damage caused by frequency converters has attracted more and more attention, people still do not know the mechanism causing this phenomenon, let alone how to prevent it.

1

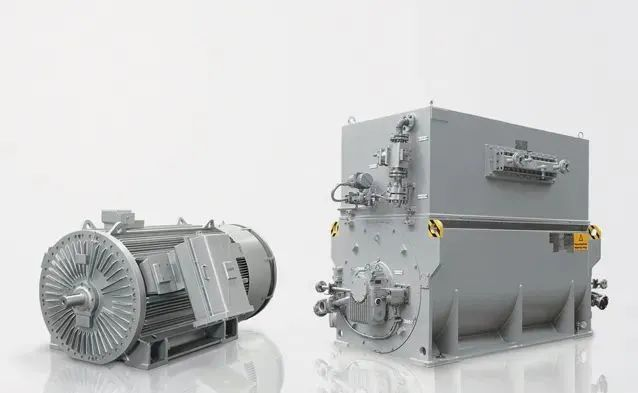

Damage to motor caused by inverter

2

The difference between inverter drive and industrial frequency drive

3

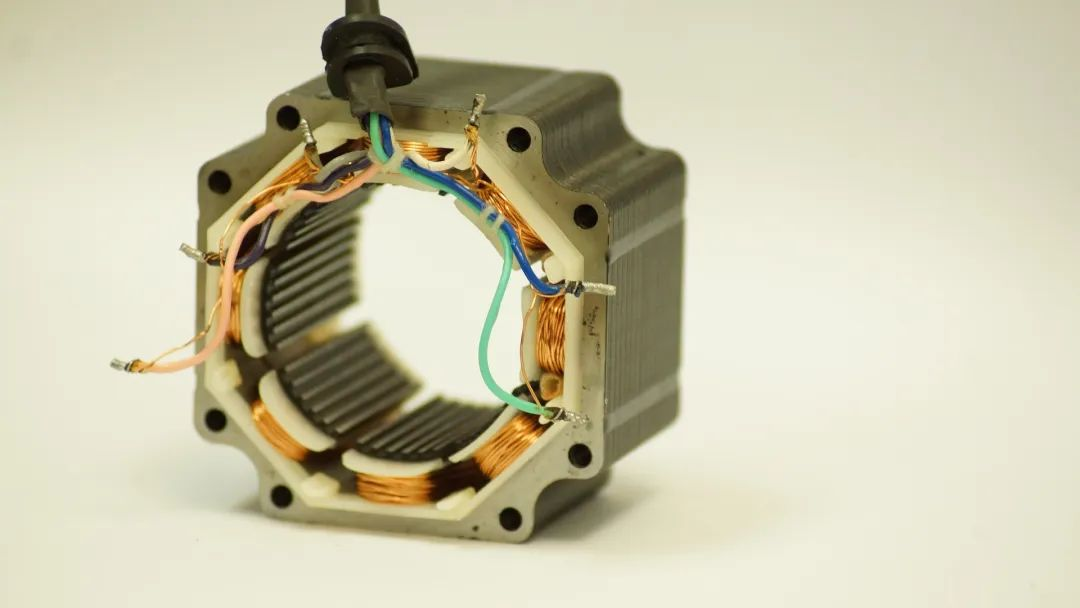

The mechanism of inverter damage to motor stator windings

4

The mechanism of inverter damage to motor bearings

5

Protection of motor stator windings

XINDA

XINDA