Technology used in brushless motors

In this section, we will explain the efficiency aspects of brushless motors and compare them with AC motors.

5.5 High efficiency and energy saving

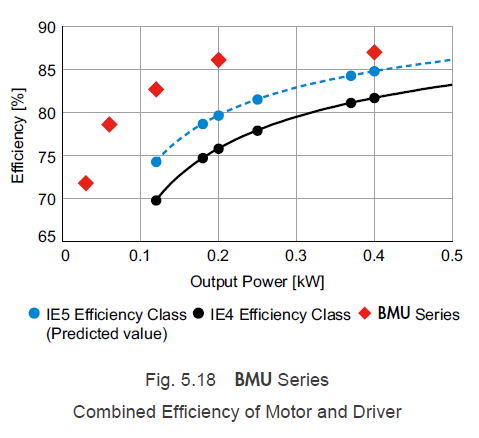

According to the "2016 World Energy Outlook" released by the IEA (International Energy Agency), more than half of the world's electricity consumption is related to motors. Reducing energy consumption is a global issue, and regarding improving motor efficiency, the international standard IEC 60034-30-1 defines efficiency classes for induction motors from 120 W to 1,000 kW. Currently, a rating up to IE4 has been established, but an IE5 efficiency rating will be introduced, which is said to reduce losses in IE4 motors by 20%. Please refer to Figure 5.18.

Brushless motors with built-in permanent magnets do not fall under IEC 60034-30-1, but are more efficient than three-phase AC induction motors. The efficiency of the motor combined with the drive circuit exceeds the IE5 efficiency level (expected value). Here, we will mainly use Dongfang Motor’s BMU series products as an example to explain the loss reduction technology of brushless motors.

5.5.1 Motor losses

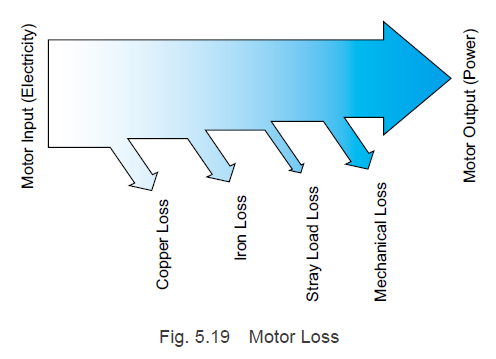

The loss categories are shown in Figure 5.19. Motor losses are divided into copper losses, iron losses, stray load losses and mechanical losses. Generally speaking, a large number of losses in motors include copper losses and iron losses. In addition, the smaller the motor, the greater the proportion of copper losses, so it is important to take effective loss reduction countermeasures based on the size of the motor.

The following describes the main types of losses and techniques for reducing losses.

5.5.2 Copper loss

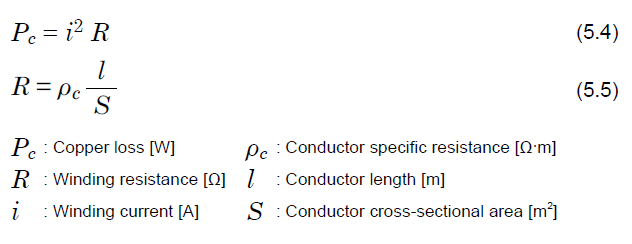

Copper loss refers to the Joule loss caused by current flowing through copper wires, and can be calculated by the following formula.

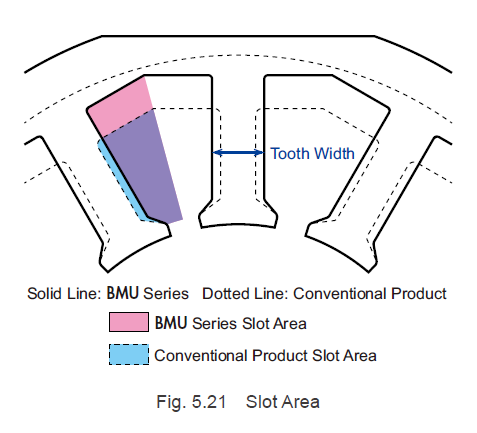

As shown in equation (5.4), the lower the current value and winding resistance value, the smaller the copper loss. In addition, it can be seen from equation (5.5) that the larger the cross-sectional area of the conductor, the lower the winding resistance and the lower the copper loss. Therefore, it is crucial to wrap thick copper wire with a high duty cycle. The ratio of the slot cross-sectional area occupied by the copper wire (the cross-sectional area of the stator and the copper wire winding) is called the space coefficient. The larger the value, the less unused space there is for the copper wire winding.

A. Present value decreases

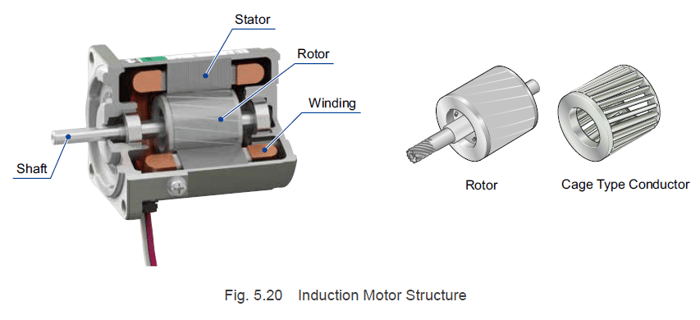

Due to the rotating magnetic field generated by the stator, an induction motor produces torque when an induced current flows through the cage conductors inside the rotor. Therefore, the winding current includes the current used to generate torque and the current used to generate induced current. Additionally, copper losses occur in the stator windings and cage conductors due to winding currents and induced currents.

Since brushless motors use permanent magnets in their rotors, no induced current is required. Since only current is required to produce torque, they can reduce winding current unlike induction motors. Since there are no copper losses in the rotor, the copper losses in the stator winding can be reduced, so the copper losses are less than in induction motors.

b. Reduce the winding resistance value

Brushless motors developed in recent years, including the BMU series, use neodymium sintered magnets with a magnetic energy product six times that of traditional neodymium bonded magnets. Due to the increased magnetic flux density from the rotor magnets, the number of turns of the coil can be reduced compared to conventional products with the same output power.

However, due to the increase in magnetic flux density, the tooth width needs to be enlarged, as shown in Figure 5.21. To this end, a frameless structure without a motor casing is adopted, the outer diameter of the stator core is increased, and the slot area is increased. Additionally, techniques to increase line alignment have been developed. These measures make it possible to use thicker conductors, thereby reducing winding resistance and copper losses.

In addition, the increased magnetic flux density not only reduces the number of turns in the coil, but also shortens the length of the stator core.

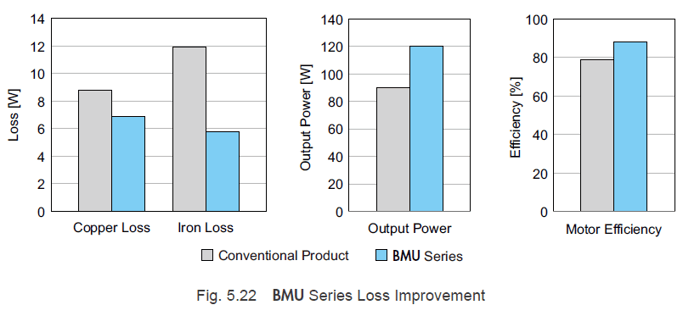

The BMU series uses high-performance magnets and improves the space factor by improving the stator shape and winding technology. Compared with traditional products, the stator core length is halved and copper loss is reduced by 11%.

5.5.3 Iron loss

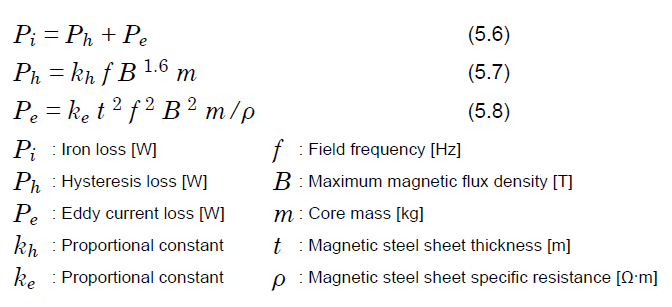

Iron losses are divided into eddy current losses and hysteresis losses. As the magnetic flux density changes with time and flows through the stator core and rotor core, eddy current losses occur in the core. Hysteresis losses occur in the magnetizing energy generated by alternating magnetization. They are represented by the following formulas.

As shown in equations (5.7) and (5.8), factors related to motor iron loss can be divided into:

Proportionality constant and resistivity determined by the material of the magnetic steel sheet

Thickness of magnetic steel sheet

Excitation frequency, maximum magnetic flux density and core mass are determined by the motor design

To reduce iron losses in motors, thin electromagnetic steel sheets with low iron losses, high saturation flux density, and good frequency dependence are ideal, but each of these characteristics requires a trade-off. Additionally, which features are used depends on the desired motor characteristics due to processability and cost considerations. Regarding design-related elements, the magnets used and the balance between copper losses and iron losses need to be optimized.

Tip: Hysteresis loss and eddy current loss

For more information about hysteresis losses and eddy current losses , see Design World's article "Hysteresis losses and eddy current losses: What's the difference?" on motion control tips.

BMU series and BLE2 series new generation brushless motors use high-performance magnets. The stator length is half that of traditional motors, and combined with high-performance magnetic steel sheets, the iron loss is reduced by 50%. Utilizing these technologies, the BMU series has an overall length that is 12% shorter than conventional products, an output power that is 33% higher, and an efficiency that is 7% higher.

5.5.4 Stray load losses

The losses remaining after subtracting the copper losses, iron losses and mechanical losses from the total losses in the motor are the stray load losses. By convention, this is considered an unexplained loss. However, in recent years, with the advancement of analysis technology, stray load losses have begun to appear as local losses caused by leakage flux, etc.

5.5.5 Mechanical losses

Mechanical losses in motors refer to friction losses in bearings, oil seals and other mechanical contact areas. One example is the loss in windage due to the type of cooling fan installed in most induction motors. Brushless motors have low losses and do not require internal cooling fans, which can suppress mechanical losses.

5.6 Small and lightweight motor

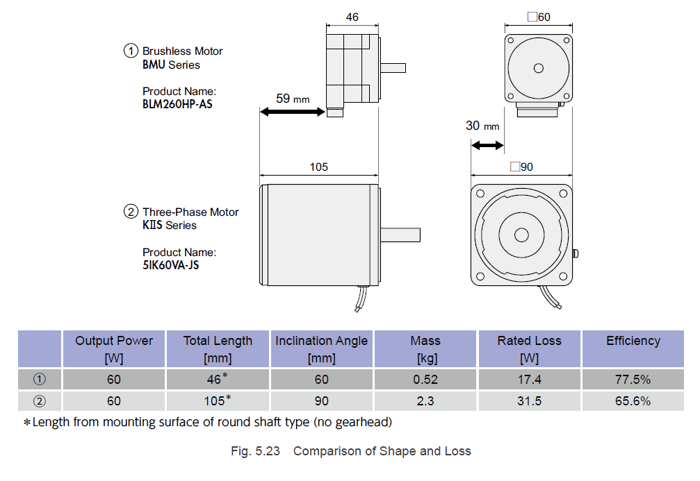

Brushless motors are smaller and lighter than three-phase AC motors while still providing the same output power rating. The rated output power of a motor is the output power when the temperature rise of the components used (mainly windings) meets the allowable temperature range when the motor operates continuously under certain conditions specified in the specification, such as ambient temperature, power supply voltage, etc.

Thanks to the high-efficiency and energy-saving technology explained in "5.5 High Efficiency and Energy Saving", the motor loss of the brushless motor is very small. The temperature rise of the motor balances losses and heat release, so the smaller the losses, the smaller the motor can be.

Figure 5.23 shows a comparison of the shapes and losses of a brushless motor and a three-phase AC motor with the same output power.

Because the motor is small and lightweight, the machine is also smaller and lighter. Especially for battery-driven vehicles, miniaturization and lightweight are emphasized because they are directly related to the battery life of the vehicle.

XINDA

XINDA