The comparison in production automation between small motors and large motors

Compared with the production automation of small motors, why is the production process of large motors still so "backward"?

At present, China's motor manufacturing process is relatively mature, and the production automation of small and medium-sized motors is basically close to 100%. But why is the manufacturing process of large motors still so "backward"? Today we will see how the next large motor is manufactured.

To build a giant motor , the first step is to build the corresponding mechanical equipment and auxiliary facilities. The second step is to process and assemble parts. The movement of large parts is realized by cranes, and some turning, milling, planing, etc. are processed by special machine tools.

1. Iron core pressing

The press-fitting process of the stator core and rotor core of large motors is done by robots. The height of the robot can be adjusted according to the height of the iron core stack.

After the core pressing is completed, it will be transported by the crane to the next working platform---the stator coil assembly.

2. Manufacture of stator coil

The maximum length of the stator coil of a large motor can reach more than ten meters, and the insulation is wrapped by an automatic tape machine. There are generally two processes for insulation treatment: VPI and hot molding.

3. Stator Coil Assembly

After the coil is manufactured, it relies on manual coil assembly. Because the coil is slender and needs to pass through the stator cavity, it is not convenient for mechanically assisted assembly, so it is basically purely manual installation at present.

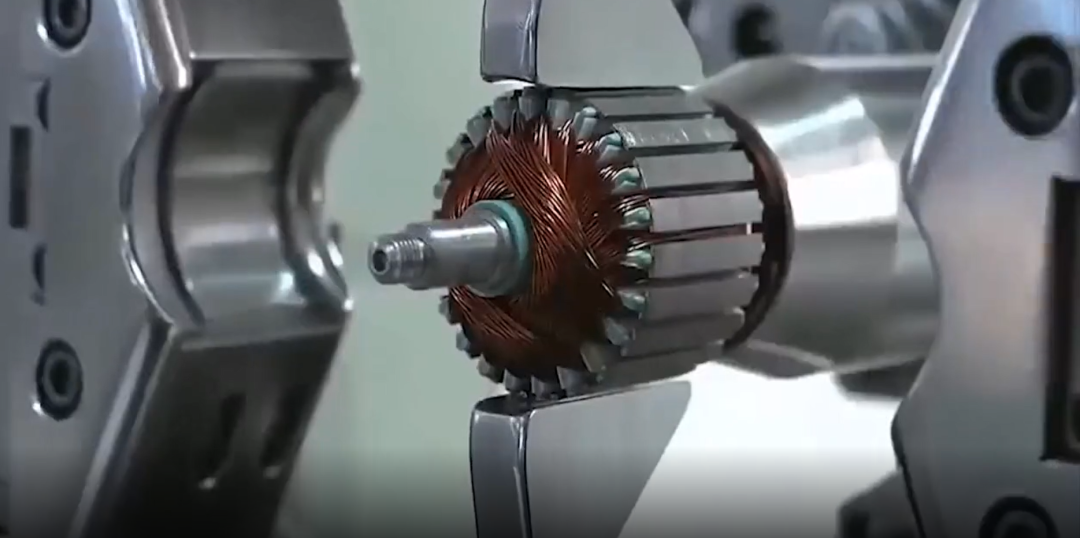

4. Rotor Coil Assembly

Like the stator coil, the rotor coil is first wound into a coil group, and then a coil group is embedded in the rotor slot as a whole. It usually requires five or six people to lift it together to assemble it.

5. Processing of stator frame

External processing of machine base shell

In-chamber machining

6. Rotor dynamic balance

7. The rotor penetrates the stator

In motor manufacturing, the quality of products made of the same design structure and the same batch of raw materials often varies greatly (the difference in iron consumption can reach 40%, and the difference in the dielectric strength of the coil can reach 80%. The service life is several times different.) The reason for this is that, in addition to the factors of raw materials, purchased parts, and outsourced parts, an important reason is that the process is not perfect or not carefully processed according to the process regulations.

At present, the production scale of motor varieties is getting larger and larger, and the degree of automation is getting higher and higher, and the requirements for the operation reliability and quality stability of the motors used are becoming more and more stringent.

Therefore, adopting a reasonable process plan and process method and implementing it carefully are the main conditions necessary to ensure the quality of the motor. The larger the production volume, the more special equipment and tooling are used, and the more meticulous the workmanship, the higher the production efficiency, the lower the product cost, and the more stable

XINDA

XINDA