Why are the motor stator and rotor not made in one piece but one piece by one piece?

Date:2023-08-01 Author:Shandong Xinda Motor Co., Ltd.

★Because three-phase or single-phase asynchronous motors use the principle of electromagnetic induction to transmit electric energy from the stator of the motor to the rotor through the coupling of the rotating magnetic field, and output mechanical energy from the rotor. It has many similarities with the transformer, so some analysis methods of the transformer are also applicable to the analysis of the stator and rotor of the motor.

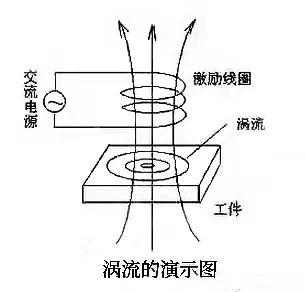

★The eddy current of AC exists in power transformers, three-phase AC induction motors, generators and other equipment. The eddy current is invisible but it exists.

The principle of electromagnetic induction is used in electrical equipment. The existence of eddy current mainly affects the utilization rate of electric energy in the AC circuit. Because eddy currents can generate Joule heat, the heat generated is proportional to the square of the current. For applications such as motors, generators, and transformers, this general law of heat is a waste of electrical energy. If it is a three-phase AC motor, since the stator coil and the rotating part of the rotor use the air gap to transmit the induced electromotive force, if the air gap between them is too large, the no-load running current of the motor will increase, and in severe cases it will The motor heats up seriously and burns the stator coil. This is the effect of excessive eddy current.

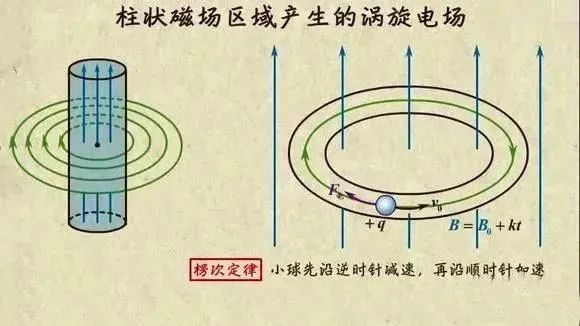

★AC eddy current is under the action of AC magnetic field. Due to the principle of electromagnetic induction, the magnetic core attached to the AC coil will have magnetic lines of force passing through the magnetic core (or silicon steel sheet), and current will pass through the closed coil conductor. At the same time, in the silicon steel sheet There are magnetic field lines passing through. The induced current is generated on the plane line perpendicular to the magnetic force line, and the current automatically forms a closed loop (that is, eddy current), so it is called eddy current. That is, any substance whose conductor changes in the strength or direction of the magnetic field can generate eddy currents. The size of the eddy current is proportional to the size of the magnetic field, the cross-sectional area of the coil and the change of the magnetic flux, and inversely proportional to the resistivity of the conductor (read Lenz's law).

Furthermore, there is a certain resistance in the silicon steel sheet magnetic core, so the existence of eddy current will cause the silicon steel sheet magnetic core to heat up, causing a part of the loss of electric energy. Therefore, when manufacturing the motor, it is necessary to leave a proper gap between the motor stator and the rotor, even if the gap is too large.

The structure of three-phase AC asynchronous motor

The main components of the three-phase AC asynchronous motor are shown in the figure below.

Sectional drawing of three-phase AC asynchronous motor

It consists of two parts, the stator and the rotor.

1. Stator

The stator refers to the stationary part of the motor. It is mainly composed of machine base, stator core, end cover, stator three-phase symmetrical winding and so on. The frame is usually made of cast iron or steel. The stator core is press-fitted in the frame. The stator core is a part of the magnetic circuit of the motor. In order to reduce iron loss, silicon steel sheets with a thickness of 0.5 mm are stacked into a circular shape and pressed into the frame.

On the inner circumference of the iron core N, a number of evenly distributed slots are punched for embedding in the three-phase winding of the stator. The stator winding of a small motor is generally made of enameled wire. The three-phase symmetrical winding of the asynchronous machine has a total of 6 outlets. The start and end of each phase winding are represented by U1, V1, W1 and U2, V2, W2 respectively. Usually, they are all drawn out from the junction box on the machine base. The three-phase symmetrical stator windings can be connected in a star shape or in a delta shape, depending on the line voltage of the power supply and the rated voltage of the winding. For example, the line voltage of the power supply is 380v, and the rated phase voltage of the motor stator group is 220v, then the winding must be connected in a star; if the rated voltage of the winding is 380v, the winding must be connected in a delta. See the picture below

Only in this way can each phase winding be guaranteed to work under its rated voltage. There are certain regulations on the arrangement of the outlet terminals of each phase winding on the junction box.

2. Rotor

The rotor is the rotating part of the motor, which is composed of a rotating shaft, a rotor core, a rotor winding, and a fan.

The rotor core is also stacked into a cylinder with 0.5mm thick silicon steel sheets, and the rotating shaft is pressed in the middle. The outer circular surface is punched with a number of evenly distributed slots, and the rotor winding is placed in the slots. diangon.comAccording to the different structural forms of the rotor winding, asynchronous motors are further divided into two forms: squirrel-cage rotor and unified-wire rotor.

The squirrel-cage rotor is a squirrel-cage rotor with bare copper bars embedded in the rotor core slot, and the two ends of the copper bars are respectively welded to two copper rings.

(also known as end ring), because its winding shape is similar to that of a squirrel cage, it is called a squirrel cage motor.

In order to save copper, the current squirrel-cage motors below 100 kilowatts generally use cast aluminum rotors for their rotor junctions. Cast aluminum rotors are cast in molten aluminum in the rotor core slot by pressure casting or centrifugal casting, and The rings at both ends and the inner fan are also cast together. It simplifies the manufacturing process and reduces the cost of the motor.

XINDA

XINDA