Motor speed regulation requirements under different working conditions

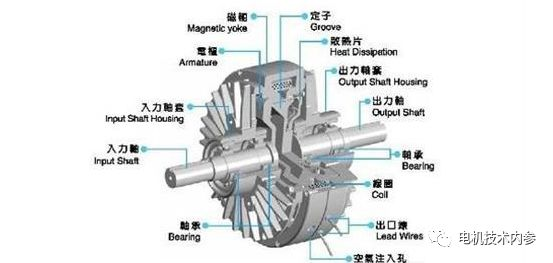

Composed of a single-speed or multi-speed squirrel-cage asynchronous motor and an electromagnetic slip clutch , it is also often called a slip motor and is a constant torque AC stepless variable speed motor.

Electromagnetic speed regulation or slip motor has excellent speed regulation characteristics such as wide speed regulation range, smooth speed regulation, large starting torque, and small control power. It has a series of advantages such as simple and reliable high-speed control, high mechanical properties and hardness, so it is widely used in printing machines and staplers, perfect binding, high-frequency drying linkage, chain boiler grate control.

The core of the electromagnetic speed regulation is the electromagnetic slip clutch. The claw poles with relatively fixed polarity and alternately distributed N poles and S poles rotate under the drag of the asynchronous motor. The solid armature cuts the magnetic force lines to induce eddy currents. Under the action of rotation, the output shaft is driven to output mechanical power. By adjusting the claw pole excitation current, the coupling degree or speed difference between the eddy current magnetic field and the claw pole magnetic field can be adjusted, so as to realize speed regulation. If the solid armature is synchronized with the rotation speed of the claw pole magnetic field, it is impossible to induce eddy current, and the solid armature loses the driving force of rotation—electromagnetic force, so it is also called electromagnetic slip speed regulating motor . It is not difficult to imagine that this type of motor is a combined structure, mainly composed of a drag motor, an electromagnetic slip clutch and a tachogenerator . Command to increase or decrease solid armature speed.

The typical motor that uses electromagnetic slip principle for speed regulation is YCT series electromagnetic speed regulation three-phase asynchronous motor, which is widely used in the occasions of speed regulation and tension control of constant torque loads , and is more suitable for occasions of blower and pump loads. For loads with high starting torque and large inertia, it has the function of buffering and starting, and at the same time has the protection function of preventing overload .

Advantages : simple structure, small capacity of control device, and cheap value. Reliable operation and easy maintenance. No harmonic interference.

Disadvantages : large speed loss. Because the electromagnetic slip clutch itself has a large slip, the maximum speed of the output shaft is only 80% to 90% of the synchronous transfer of the motor; during the speed regulation process, the slip power is all converted into heat loss, resulting in low efficiency and serious heating problems.

Frequency conversion speed regulating motor is a general term for motors driven by frequency converters . Variable frequency speed motor is referred to as variable frequency motor, which is a general term for motors driven by frequency converters. In fact, the motor designed for the frequency converter is a special frequency conversion motor, and the motor can achieve different speeds and torques under the drive of the frequency converter to adapt to changes in load requirements. The variable frequency motor is developed from the traditional squirrel cage motor, changing the traditional motor fan into an independent fan, and improving the insulation performance of the motor winding. In occasions with low requirements, such as low power and frequency at the rated operating frequency, ordinary squirrel cage motors can be used instead .

Frequency conversion speed regulation is to change the synchronous speed of the asynchronous motor by changing the frequency of the input power at the stator end of the asynchronous motor and making it continuously adjustable. Ms. The old customer of the senior salesman in the company wants to get involved in environmental protection projects. Frequency conversion motors should be the best option, with mature technology and high comprehensive economic indicators.

Advantages : no additional slip loss, high efficiency, wide speed regulation range; for occasions where the low-load running time is long, or the start-stop operation is frequent, the purpose of power saving and motor protection can be achieved.

Disadvantages : The technology is more complicated and the price is higher.

In some special drag circuits, two-speed motors are required ; sometimes even three-speed or four-speed motors are required. The principles and control methods of these multi-speed motors are basically the same. It is mainly used in various transmission machinery that requires step-by -step speed regulation according to the nature of the load, such as machine tools, mining, metallurgy, textile, printing and dyeing, chemical industry and other industries. The multi-speed requirements of the same motor can be solved by different connections of the same winding and multiple windings of the same motor.

Pole-changing speed regulation is to change the number of magnetic pole pairs of the motor by changing the wiring mode of the motor stator winding , so that the synchronous speed can be changed step by step , and the step-wise speed regulation of the motor speed can be realized . This speed-regulating motor is currently available in a series of finalized products, such as single-winding multi-speed motors.

Advantages : no additional slip loss, high efficiency; simple control circuit, easy maintenance, low price; cooperating with electromagnetic slip clutch can obtain smooth speed regulation with high efficiency.

Disadvantages : stepless speed regulation, stepless and smooth speed regulation cannot be realized. Moreover, due to the limitation of the motor structure and manufacturing process, usually only 2 to 3 kinds of stepwise speed regulation with pole pairs can be realized, and the speed regulation range is quite limited.

There are many occasions in the industry that require speed regulation, such as driving, fans, conveyor belts, machine tools, etc. The use of pole-changing speed regulation has the characteristics of low cost, low power consumption, and good output torque rigidity. Now, the two-speed motor still has a certain application space.

The DC motor is a stepless speed-adjusting motor with the best speed-regulating performance, but its operating speed is greatly limited due to the existence of an item changer.

Advantages: Excellent speed regulation performance, diversified speed regulation methods, and high operating efficiency.

Disadvantages : It cannot be used for high-speed operation, and must be equipped with carbon brushes and commutators.

Both the permanent magnet synchronous motor and the permanent magnet brushless motor realize stepless speed regulation through PWM frequency conversion speed regulation device . Permanent magnet motors are widely used in industries such as aerospace, shipbuilding, medical treatment, and new energy vehicles. On the one hand, there is no need for electric excitation, and there is no excitation loss and corresponding heating factors; on the other hand, stepless speed regulation can be realized and the speed regulation range is almost unlimited. any restrictions.

Advantages: Stepless speed regulation, theoretically there is no limit to the speed regulation range.

Disadvantages: Magnets are expensive and have problems with loss of magnetism.

XINDA

XINDA