Can the motor core also be 3D printed? New Developments in Research on Magnetic Cores for Motors

Date:2023-07-12 Author:Shandong Xinda Motor Co., Ltd.

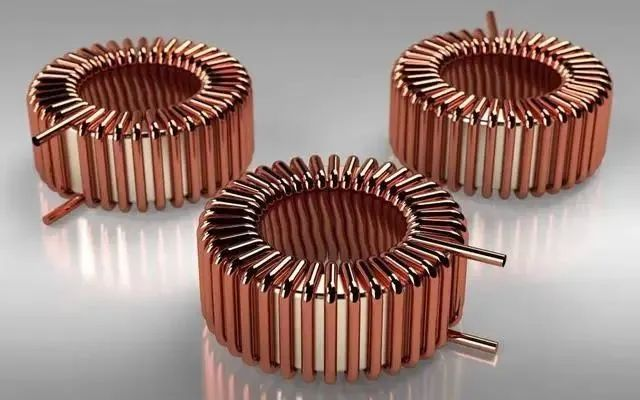

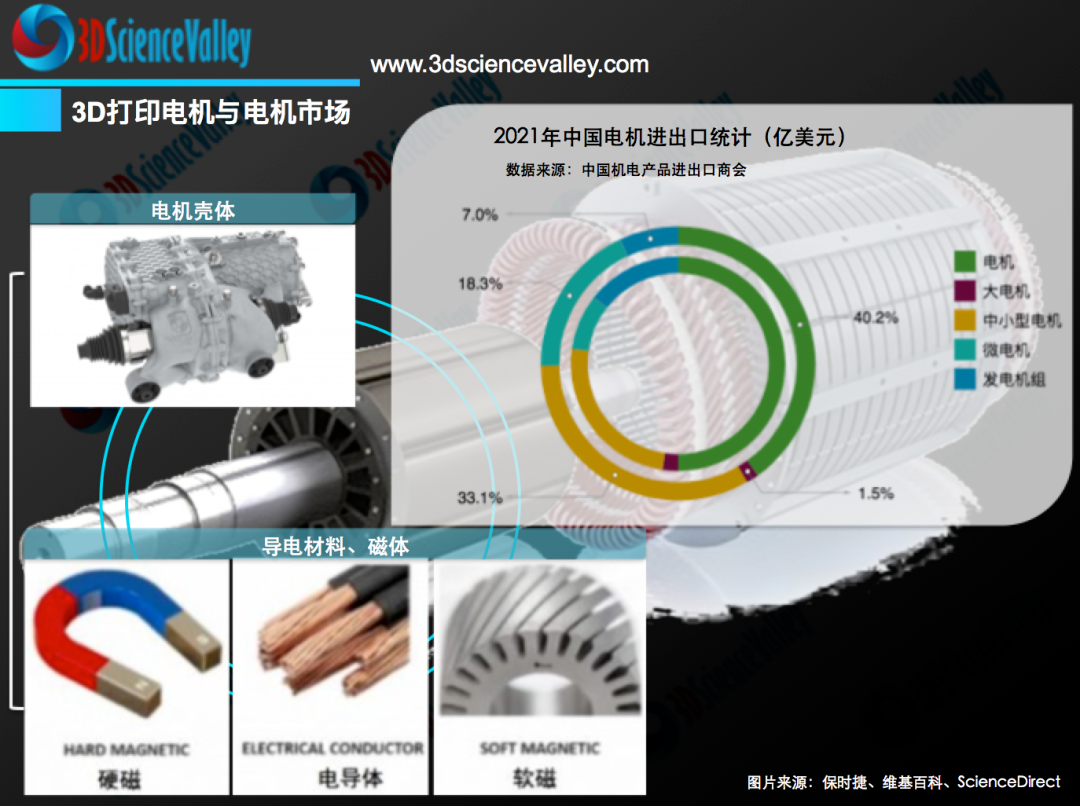

The magnetic core is a sheet of magnetic material with high magnetic permeability. They are commonly used for field guidance in a variety of electrical systems and machines, including electromagnets, transformers, motors, generators, inductors and other magnetic components.

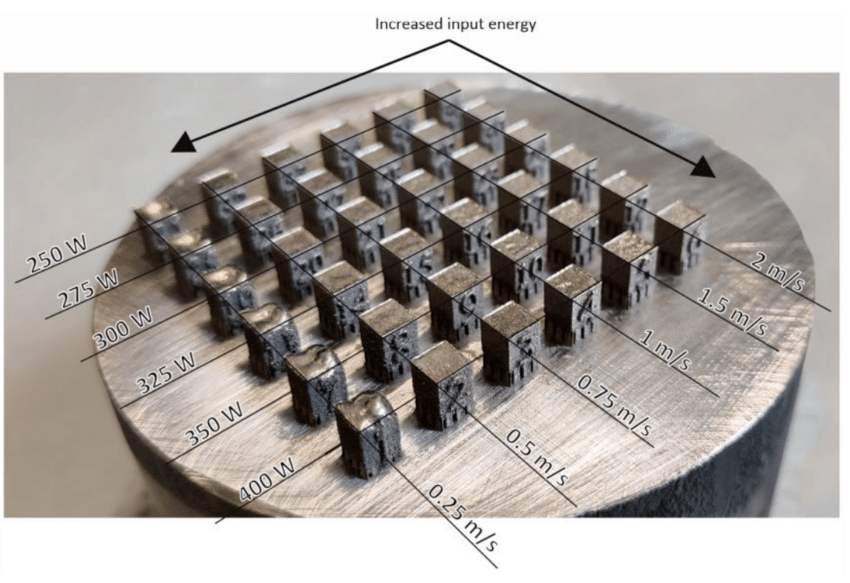

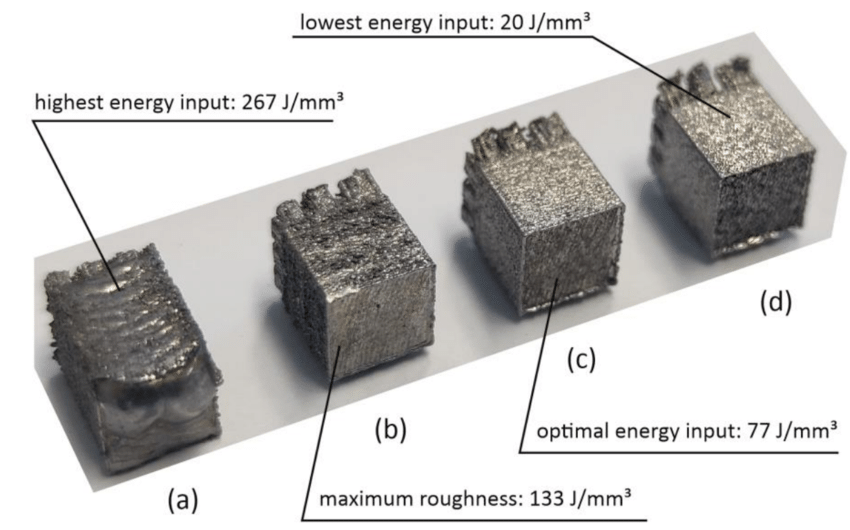

So far, the 3D printing of magnetic cores has been a challenge due to the difficulty of maintaining the efficiency of the magnetic core. But a research team has now proposed a comprehensive laser-based additive manufacturing workflow that they say can produce products with superior magnetic properties to soft magnetic composites.

Optimized 3D printing workflow

XINDA

XINDA